At Manufacturing Solutions 2018, taking place at the Limerick Institute of Marketing, Ireland, on 13th June 2018, the latest version of VERICUT, V8.1, will be featured on CGTech’s stand 44. VERICUT is the world’s leading independent machine simulation, verification and optimisation software, simulating all types of CNC machining, including drilling and trimming of composite parts, water jet, riveting, robots, mill/turn and multi-axis machine tools. It operates independently, but can also be integrated with leading CAD/CAM systems.

A key focus for the exhibition will be the time savings that can be achieved using the comprehensive capabilities of VERICUT. As Managing Director, Tony Shrewsbury, explains: “In today’s globally competitive environment, software verification is essential to the ability of any manufacturing business to attain the goals of producing on-time, high quality parts at a minimum cost. VERICUT helps companies achieve these goals in five significant areas.”

These five areas include avoiding costly collisions, scrap parts and broken tools as VERICUT’s virtual environment offers the opportunity to program parts, determine their accuracy and verify post processed NC code for any CNC machine, offline at a workstation. Secondly, the VERICUT digital twin of any machine tool identically reflects the static and dynamic attributes of your real machine, which can rapidly speed up the introduction of new equipment on to the shop floor.

For many machine shops any capacity shortage is a serious issue and by doing the prove-out process on a computer, in the VERICUT virtual world, it frees up your CNC machines for round the clock production, while reducing costs and improving quality. VERICUT also provides a great opportunity for training programmers, operators, and apprentice’s offline.

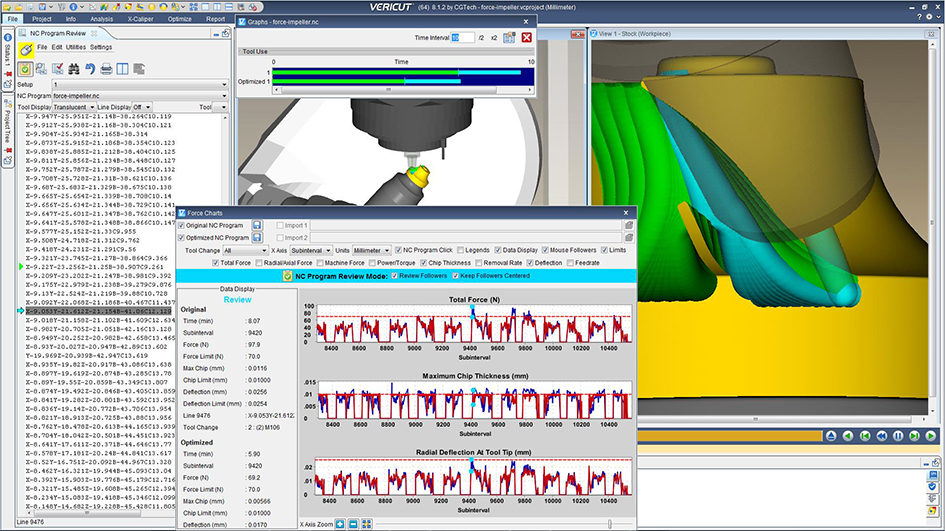

Finally, VERICUT of course optimises the CAM program to modify feed rates to make the tool path faster and more efficient, ensuring any parts are machined safely and in the least amount of time. This capability has recently been enhanced with the introduction of the new Force module.

Force is a physics-based optimisation method that determines the maximum reliable feed rate for a given cutting condition based on four key factors: force on the cutter, spindle power, maximum chip thickness, and maximum allowable feed rate. It calculates ideal feed rates by analysing tool geometry and parameters, material properties of the stock and cutting tool, detailed cutting tool geometry, and VERICUT cut-by-cut contact conditions. Force interpolates cutting conditions using a proprietary set of materials coefficients to account for the strength of material and the effects of friction and temperature. The materials data is generated by actual machining tests and does not rely on extrapolating from finite element analysis results. The bespoke cutting coefficients used by Force result in the most accurate cutting force calculations available today.

For more information, visit the CGTech website at www.cgtech.co.uk, call +44 (0)1273 773538, or email info.uk@cgtech.com.