The latest release of the market-leading sheetmetal software, Radan, includes new functionality giving users a greater degree of manual control where flexibility is required for certain aspects of their individual production processes.

Product Manager Olaf Körner says while Radan 2018 R2 continues to provide important automation tools for improving productivity, users’ knowledge and experience of a company’s components can address certain specifics that are often unique to their own manufacturing procedures.

“Full automation is ideal for simple parts. And while automation also plays a big role in manufacturing complex parts, there’s often the need for some manual input as well, so we’ve added a number of more focused tools to allow them to easily take control of that.”

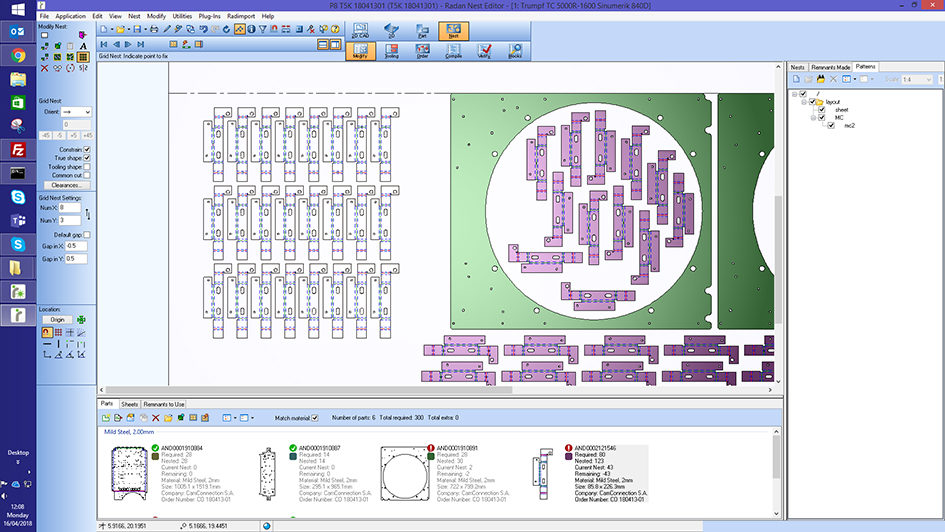

One such new tool is Grid Nesting, which gives additional flexibility for users wanting to create or manipulate a nest manually. “For example, if a sheet isn’t completely full, they can either let the automatic nester take over, or, if they have a clear idea of what they want to do, this new function provides an easy way of filling a space with a particular part. Users can even stipulate the direction they want individual parts nested in.

“The previous version allowed you to manipulate the automation to get the result you want, but grid nesting achieves it much faster.”

Reverse Cutting Direction is another example of providing additional user control. Olaf Körner says this new functionality is particularly important for plasma CNC machine tools. “Plasma cutting of thicker material often generates considerable heat, which can cause the metal to distort. This can now be resolved with a single mouse click to simply reverse the cutting direction on certain areas of the material where there might be an issue.”

Moving on to the new automation functions – a major update is an improved way of calculating the most effective remnants. Previously, the operator had to manually choose the shape of the remnant – a square or rectangle – but the Improved Remnant Handling function, ensures the best possible option is always cut.

Picker Arm Movement provides additional automation on the machine tool. “Automated systems manipulating the part after it’s cut are becoming increasingly popular, even for large, complex different shaped and sized components,” he says. “Radan now automatically predicts the best way to handle the part, so the operator doesn’t have to make that decision.”

Picker Arm Movement provides additional automation on the machine tool. “Automated systems manipulating the part after it’s cut are becoming increasingly popular, even for large, complex different shaped and sized components,” he says. “Radan now automatically predicts the best way to handle the part, so the operator doesn’t have to make that decision.”

A single click now creates a detailed Production Pack for all nests. Every NC program traditionally comes with an instruction sheet for the shop floor, which until this latest version, was a manual process for each individual nest. Now, one mouse click introduces additional information into the pack, which is produced automatically for any number of nests. “Some jobs could contain up to 50 nests or more, so this is a major time-saver.”

RADBEND

With the dedicated press brake module, Radbend, making a major contribution to Radan’s global growth, a new set of Automation Options means templates can be created to specify steps which previously had to be set up manually. It not only applies to the part shown onscreen, but also to the same repetitive work for other parts without the user having to do anything.

DIN Unfolding enhances the way a part is unfolded in Radbend, placing more emphasis on the designer’s intentions, particularly regarding the importance of the radius.

Improvements to the Bend Sequence Templates allow information to be brought in detailing where joggles and hems should occur. Olaf Körner says: “When we calculate automatic sequences the operator can specify rules…but joggles and hems are complex, time consuming, operations. These templates give the option of carrying them out in one place before moving on to another operation.”

Show Unfold Dimensions is an onscreen overview showing the key dimensions of the blank. It also appears on all reports so operators can readily check they have the correct part, streamlining the shopfloor process.

RADM-AX / RADTUBE

As Radm-ax continues to develop its relationship with Mazak, providing software for their powerful and complex tube cutting machine tools, Olaf Körner says Common Cutting for Tubes is an important enhancement. “Separating tubes by just one cut, instead of cutting the end of each tube individually, improves efficiency, especially on thick, complex tubes with large diameters.”

The new Auto-Cut Review function provides assisted automation for more complex parts. “Software can’t cater for everything about a particular business – its USPs or what gives it added value. So instead of trying to analyse the entire cutting strategy for a complex part, users can now review the suggested solution, and either apply it or make any changes.”

Clone Change Points is a way of duplicating manual changes. “For example, if we need the cutter to slow down a little or stop, and we need that operation repeated at multiple points, we can clone the instruction. So something that happened a few centimetres back can now be done again, time and again. It’s a quicker way of replicating the changes.”

RADAN LOGISTICS

A number of updates to Radan’s Logistics suite include giving users three different options on how they calculate the cost of material used to make an individual part. Also new to the quoting system in 2018 R2 is the ability to mark purchased items on the complete assembly drawing, and the cost per piece, so they can be included in customer quotes.

A workflow enhancement to import parts from CSV files into quotes and orders leads to a more streamlined process. “This is particularly useful when customers send CSV files with a quotation request for different quantities of different parts. All the parts can be brought into the Radan Logistics module at the same time, instead of having to upload the parts first, and then the quotation request.”

Finally, Batch Bending reduces the number of mouse clicks, by introducing all single part 3D files into the module. “Programming a press brake part involves a number of steps, and can take up to 21 clicks. But by combing everything through Radan Logistics, the operation can be automated, while flagging up anything that requires manual input. This means the operator may not need to adjust anything…and if they do, it’s only on parts that need it, rather than them having to work on all parts.”

CONCLUSION

In conclusion, Olaf Körner says: “The theme of Radan 2018 R2 has been balancing the quest for automation to improve productivity even further, with quick, manual options to give an extra degree of flexibility where required.”