WNT’s XHeadClamp system makes it possible.

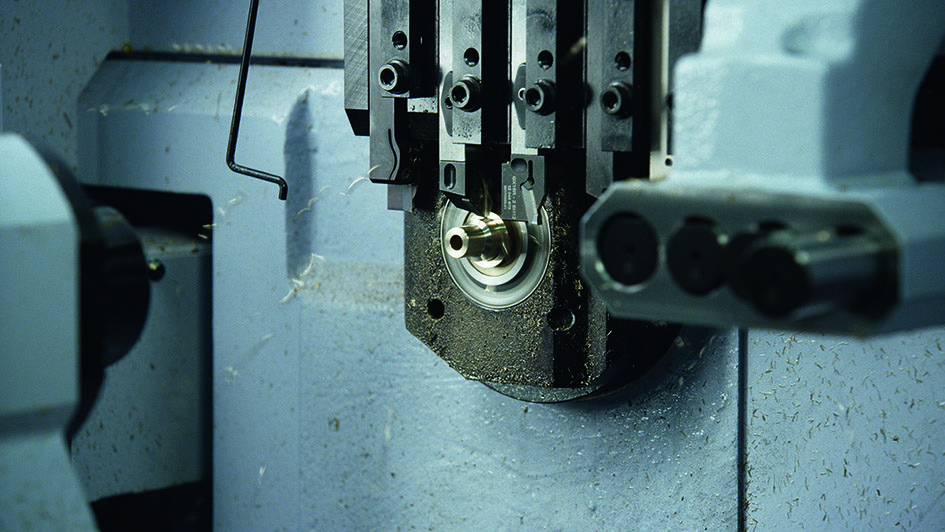

Tool Selection for Sliding Head Tooling, is the dedicated catalogue from WNT for all users of sliding head machines. The catalogue contains details of over 11,000 cutting tools and accessories designed especially for sliding head lathes, including 5,000 completely new products to the WNT range.

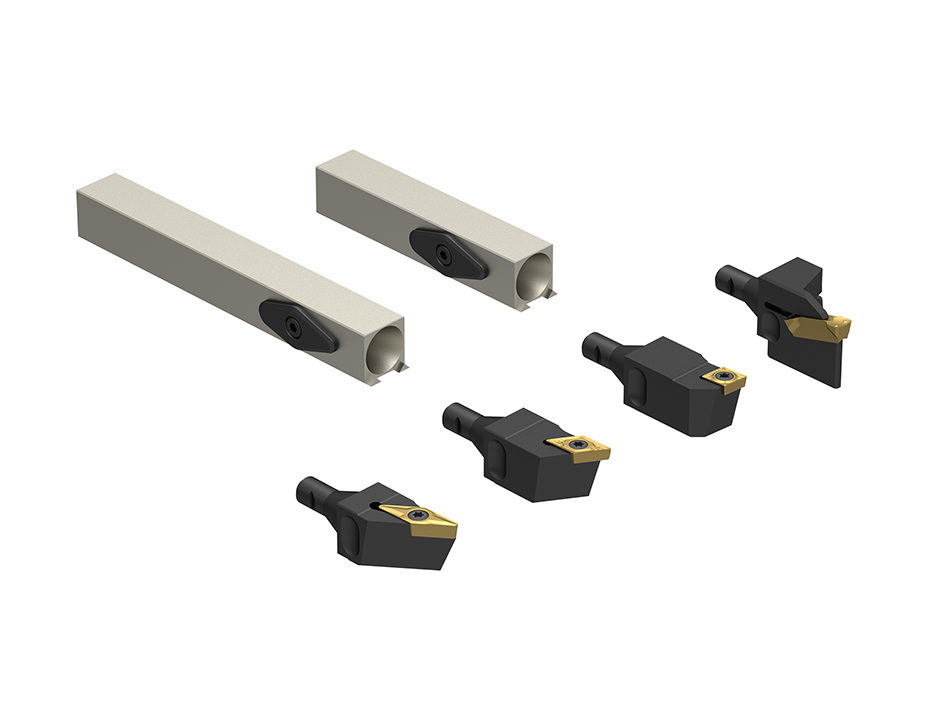

Among these new tools is the innovative XHeadClamp system, which can be used to change the cutting edge or geometry of a tool in a matter of seconds. This clever exchangeable head system significantly reduces machine downtime and therefore costs. The design eliminates, in most cases, the need to re-datum tools even when changing from one insert style to another.

The basis of the XHeadClamp system from WNT is the modular interface between the square tool shank and the interchangeable cutting head. These cutting heads come with a variety of insert pockets allowing various turning, grooving and threading applications to be undertaken. Once a batch of components has been machined it is a simple procedure to exchange heads to either refresh an existing tool or to change the style of insert completely. Typically, a single screw secures the head in place, with this removed the head can be exchanged in a matter of seconds. As long as the new head contains an insert with the same nose radius the coordinates/datum points of the tool will be the same, making programming straightforward.

The simple, straightforward, uncomplicated way XHeadClamp works means the next component/batch can be machined immediately with practically no corrections needed, thereby maximising the machine’s efficiency. Process security is assured as it is impossible to fit the head incorrectly.

“The XHeadClamp reduces tool change times so significantly that set-up time savings can be maximised leaving more time for machining the workpiece after changing the cutting edge. The high repeatability and stability is also very impressive,” explains Dirk Martin, Product Manager at WNT. “The fast and secure handling and, above all, the enormous flexibility of the system should impress everyone who uses it.” The versatility of the system means that, not only can it be used for various indexable insert dimensions, but also for any indexable insert geometry within the same system size – regardless of whether they need to be positioned on the left or right. When combined with the wide selection of indexable inserts available from WNT suitable for machining a variety of materials, such as steel and non-ferrous metals, but also super alloys such as titanium or Inconel, the efficiencies are there to be taken advantage of. WNT will further develop the XHeadClamp range with the addition of through tool coolant soon. Users will be assured that the current and future development of the XHeadClamp system will be fully compatible with each other.

A copy of Tool Selection for Sliding Head Tooling can be requested by speaking to your local WNT Technical Sales Engineer, calling 0800 073 2073 or, by completing the form at the bottom of the page linked here for an informative sliding head product video https://www.wnt.com/uk/support-know-how/practical-knowledge-cutting-tools/sliding-head-tooling.html