At MACH 2018 on Stand H7-46, Tewkesbury based Quickgrind will be demonstrating the very best in UK manufactured cutting tool technology with an exhibition debut for its Eliminator range of end mills.

The rise of innovative 5-axis machining strategies from leading CAM vendors that focus upon maximum material removal rates has seen cutting tool manufacturers slip behind the curve with respect to tool geometry developments for such strategies. That was until Quickgrind launched its ground breaking Eliminator Series of end mills.

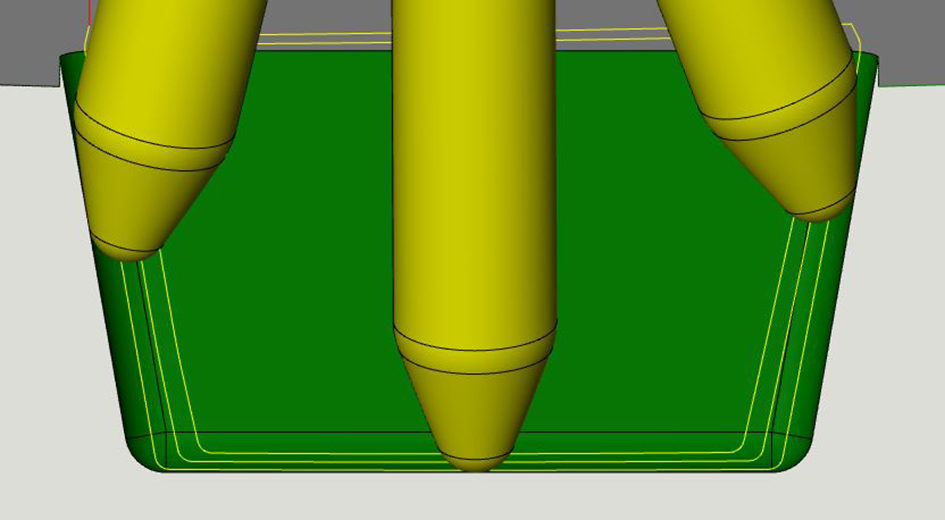

The QuickGrind Eliminator 10mm Conical Barrel Tool with Xred coating

The new series of Eliminator end mills for 5-axis machining incorporate a conical or tapered form that will deliver a cycle time reduction of up to 95%. This bold claim is substantiated by the ability of the Eliminator to significantly reduce tool path distances whilst utilising the full flute length to increase the step down rate and the subsequent material removal rates.

From an application perspective, the new Eliminator conical barrel tools are suited to semi-finish and finish machining processes on a wide range of components and materials that span the mould & die, motorsport, medical, oil & gas and particularly the aerospace sector and turbine blade production. The solid carbide end mills are available uncoated or with Quickgrind’s Type D geometry with an MX coating for the machining of low and medium alloy steel, tool steel, cast iron and hardened steels whilst the Type S end mills are XRED coated for the high performance machining of high temperature alloys such as Inconel, Hastelloy and Titanium as well as the complete range of stainless steels.

The Eliminator takes an area of a circle to form the radius of the flute, which improves the step down strategies when compared to ball nose end mills. The Eliminator series is available as a 3 or 4 flute tool as standard. The three flute and four flute end mills are offered with a shank diameter of 6, 8, 10, 12 and 16mm that respectively tapers down to a ball nose diameter of 1, 2, 3 and 4mm with a flute radius of 250, 500, 1000 and 1500mm. Custom made Eliminators have been produced as small as 1.80mm diameter with 6 flutes and 15,000mm flute radii. As always, Quickgrind pride themselves on producing tools to meet customer’s specific requirements and on a short delivery time.

These end mills are provided with an overall length from 58 to 93mm with a tapered flute length from 9.5 to 31mm. For further details on how Quickgrind can revolutionise your 5-axis machining strategies and performance with its UK manufactured cutting tools, come and see us at MACH in the GTMA pavilion Stand H7-46.