At MACH 2018, taking place at the NEC, Birmingham, from 9 to 13 April 2018, the latest version of VERICUT, V8.1, will be featured on CGTech’s stand 626, Hall 17. VERICUT is the world’s leading independent machine simulation, verification and optimisation software, simulating all types of CNC machining, including drilling and trimming of composite parts, water jet, riveting, robots, mill/turn and multi-axis machine tools. It operates independently, but can also be integrated with leading CAD/CAM systems, including Dassault Systemes CATIA, Siemens PLM NX, Autodesk PowerMill and FeatureCAM, Vero EdgeCAM, DP Technologies Esprit, CNC Software MasterCAM, Missler TopSolidCAM and Open Mind HyperMil, to provide a seamless link between the conceptual and the deliverable.

A key focus for the exhibition will be the time savings that can be achieved using the comprehensive capabilities of VERICUT. As Managing Director, Tony Shrewsbury, explains: “In today’s globally competitive environment, software verification is essential to the ability of any manufacturing business to attain the goals of producing on-time, high quality parts at a minimum cost. VERICUT helps companies achieve these goals in five significant areas.”

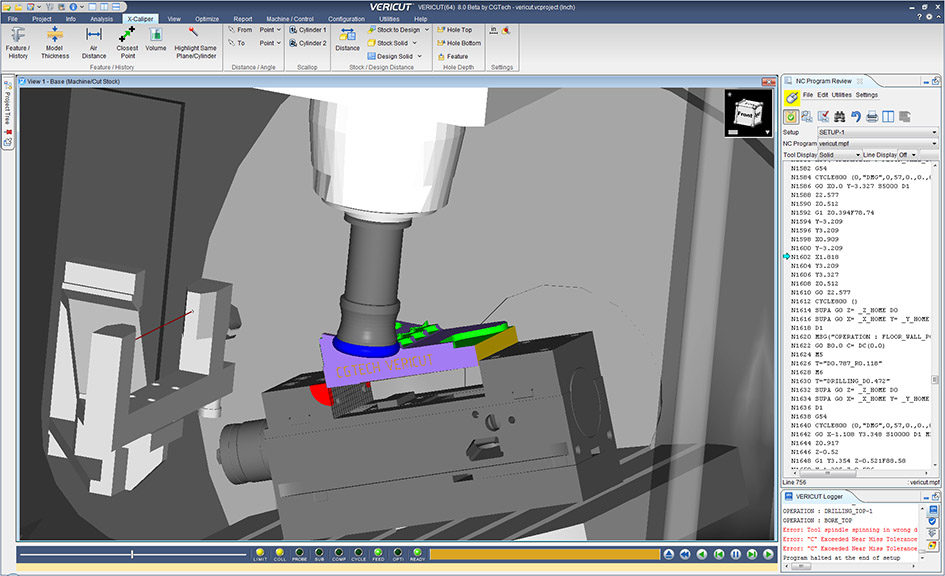

The first area that VERICUT focuses on is avoiding collisions, scrap parts and broken tools. Machine simulation within VERICUT detects collisions and near-misses between all machine tool components such as axis slides, heads, turrets, rotary tables, spindles, tool changers, fixtures, workpieces, cutting tools, and other user-defined objects. Setting up ‘near-miss zones’ around the components to check for close calls, and detect over-travel errors. Removing the risk of collisions avoids any gouging of the workpiece or raw material, with the subsequent reduction in damage to the cutting tool.

With machines modelled in a virtual world, VERICUT can speed the implementation of new CNC onto the shopfloor. As the software version of any machine tool identically reflects the static and dynamic attributes of the actual machine, any company can virtually operate any machine before it is installed. For many machine shops any capacity shortage is a serious issue. Here, VERICUT again delivers in two important ways. The first involves the relocation of any prove-outs for new parts away from the actual machine into the VERICUT virtual world. The second is the optimisation of the post processed CAM program to remove any inefficiencies.

Says Tony Shrewsbury: “Every machine shop has to introduce and prove new NC programs at some point. For most engineering companies around 10 to 15 per cent of a machine tool’s spindle time is allocated to this. On a single 10-hour shift, working 20 days per month with 12 CNC machine tools this equates conservatively to 240 lost hours. Assuming the machine is charged out at a very reasonable £70 per hour, that’s £16,800 worth of lost production time. So, the cost for a shop manually proving-out programs is over £201,000 per year.”

As VERICUT uses the same NC code to drive the machine model as that used by the actual machine it accurately reflects what the machine will do in the physical world, giving users the confidence that a proven program will run without any problems once any errors have been corrected. VERICUT simulates every leading machine tool brand, including DMG Mori, MAZAK, Makino, Matsuura, Hermle, Chiron, Starrag, WFL, Nakamura-Tome and more.

Of course, VERICUT also optimises the CAM program to modify feed rates to make the tool path faster and more efficient, ensuring any parts are machined safely and in the least amount of time. This capability has recently been enhanced with the introduction of the new Force module.

Force is a physics-based optimisation method that determines the maximum reliable feed rate for a given cutting condition based on four key factors: force on the cutter, spindle power, maximum chip thickness, and maximum allowable feed rate. It calculates ideal feed rates by analysing tool geometry and parameters, material properties of the stock and cutting tool, detailed cutting tool geometry, and VERICUT cut-by-cut contact conditions. Force interpolates cutting conditions using a proprietary set of materials coefficients to account for the strength of material and the effects of friction and temperature. The materials data is generated by actual machining tests and does not rely on extrapolating from finite element analysis results. The bespoke cutting coefficients used by Force result in the most accurate cutting force calculations available today.

Tony Shrewsbury concludes: “We will be running demonstrations highlighting all the capabilities of VERICUT at MACH, with actual customer data substantiating our confidence in the software and the benefits it can unlock for engineering businesses in the UK.”