OPEN MIND Technologies AG, one of the leading CAD/CAM software developers, will present a host of new technology advancements at the Tire Technology EXPO 2018. On Booth 6000 from 20th to 22nd February at the Deutsche Messe in Hannover, OPEN MIND will introduce its latest edition of hyperMILL®, Version 2018.1, the tire module and the hyperMILL® MAXX Machining performance package.

The tire module of the hyperMILL® CAM suite offers a range of special functions for the NC programming of tire moulds. At its heart is the Tire Clock, where the tire design is defined with all segments, tracks, pitch sequences and pitches. Automated functions support the creation and management of the elements and geometries required for programming. The user can display the suitable geometry for each operation in order to avoid errors and this means that each pitch only has to be programmed once. The new Multiple Track Support function allows a separate pitch sequence to be defined for each track.

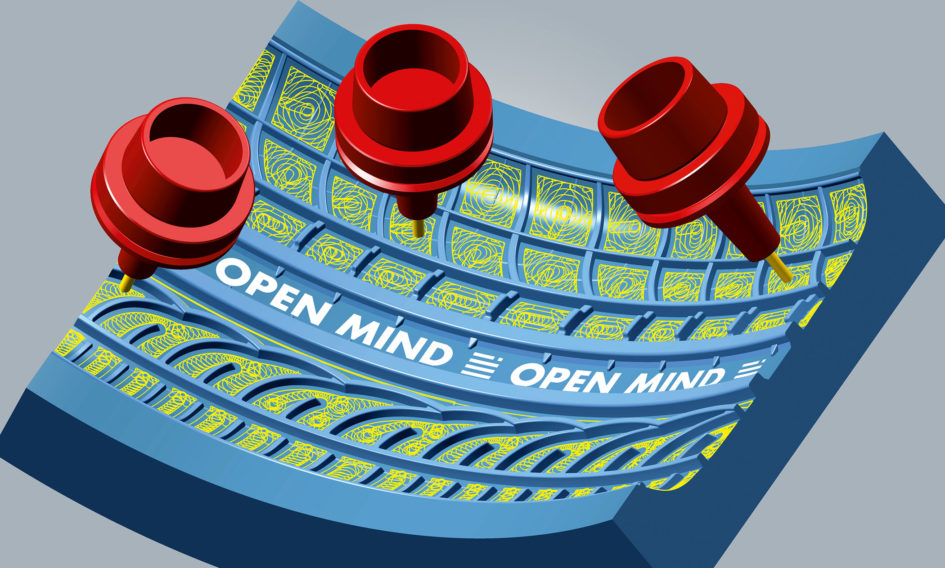

For Tire Manufacturers striving for optimal production performance, OPEN MIND will demonstrate the benefits of its hyperMILL® MAXX Machining performance package. With three highly efficient modules for roughing, finishing and drilling, hyperMILL® MAXX Machining promises a major boost in efficiency. Manufacturers that use these innovative CAM strategies will be able to achieve time savings of up to 90 percent during finishing and time savings of up to 75 percent during roughing.

Certain to draw the interest of visitors to the event will be the new hyperMILL® VIRTUAL Machining. This new simulation solution creates a perfect virtual rendering of reality in the machine based on NC data. Built with Industry 4.0 in mind, hyperMILL® VIRTUAL Machining represents a major step forward toward digitised production.

The exhibition will also be the first opportunity for the Tire Industry to witness the benefits of OPEN MIND’s latest hyperMILL® release, Version 2018.1. Innovative additions to Version 2018.1 include 3-axis simultaneous Turning. Two new strategies for simultaneous machining enable even more efficient mill/turning. Complex workpiece geometries can be machined in a single job step by simultaneously adapting the approach angle during the turning operation. In hyperCAD®-S, the new global fitting functions have been implemented. This new function allows multiple faces to be joined into one face with a defined ISO orientation.