Following the MACH 2016 exhibition at the NEC, a UK based packaging company with specialist plastics bottling applications placed an order on Mollart Engineering for a Prismabore PRB25 multi-axis, two-spindle deep hole drilling and milling centre. The order was won against strong European competition with the final purchase decision made following drilling trials which led to a massive improvement in the level of production being achieved.

During visits to Chessington to discuss the machine the customer became aware of demonstrations being run on a Drillsprint LD2-750 two-spindle gundrill. Then following trials and the machine’s capability to accommodate tight concentricity tolerances, the Drillsprint was also ordered.

The machines are being used to produce moulds for plastic bottles requiring a heavier wall section, incorporating pre-formed cores with accurate and uniform positioning of cooling holes within thin wall section areas of the moulds. Hole sizes are between 3.3 mm and 22 mm diameter by up to 400 mm deep.

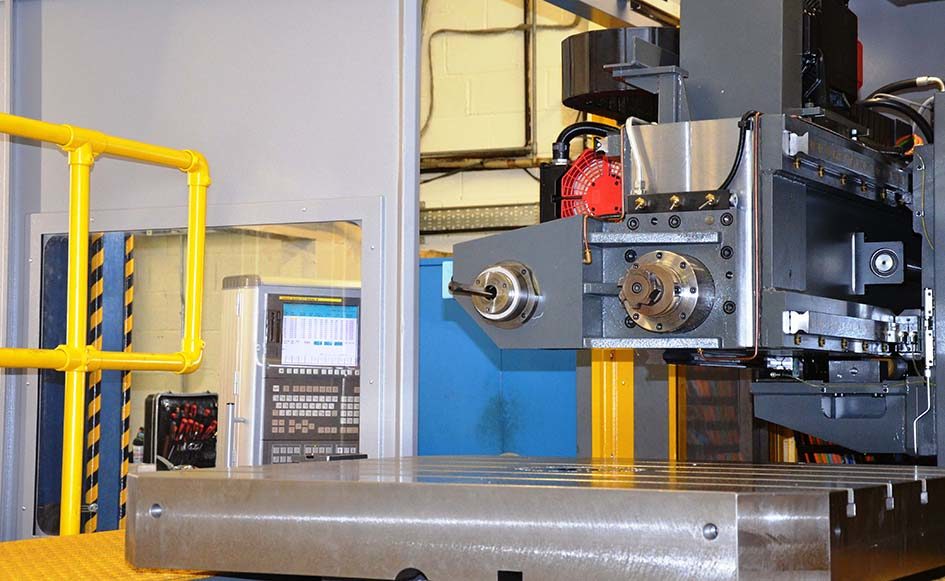

The Prismabore Column-type PRB25 deep hole drilling machine is a 5-axis, two independent spindle configuration, milling and gundrilling centre able to produce multi-feature component operations in a single cycle. Meanwhile, the Mollart Drillsprint LD2-750 being supplied, is a flexibly configured light duty gundrilling machine able to produce holes between 2 mm and 25 mm diameter by 750 mm in depth.