Following the recent installation of the latest Miyano BNE-51MSY multi-axis mill-turn centre, Wednesbury based precision subcontractor Machine Tech Engineering (MTE) has been able to slash production lead times on batches of hydraulic bodies from three weeks for the first operation plus a week for the second to machining the batch complete in just five days.

The decision to go for the 51 mm bar capacity Miyano continued the already accrued benefits from introducing new machines, for instance, a Citizen A32-VllPL CNC sliding head mill-turn centre installed recently, has just been the source of orders from a new customer in the brewing industry for 1,000 batch quantities of stainless steel pump valves. According to MTE director Warren May: “Without the Citizen we would never have dreamed of even quoting for such parts as we would be uncompetitive. But the Citizen A-Series is very quick and powerful enabling simultaneous cutting cycles.”

MTE has some 30 machines, seven bought under the Citizen brand in its freehold 7,500 ft2 machine shop from which turnover is projected to top £1 million in 2017. With recent CNC sliding head installations, MTE had already benefitted significant business increases and improvements in productivity from the ability to combine operations into single cycles which came about following a visit to MACH 2014 at the NEC.

Said director Stewart May: “We saw a sign on the Citizen stand promoting a 20 per cent regional grant. This chance sighting changed our business as with the latest machines, we knew if we could afford it we could be confident to run unmanned and so ordered a Citizen A32-VllPL. Within three months we filled its capacity and bought another!”

However, he maintains their practicality and confidence in unmanned running was restricted to 32 mm bar diameter with the sliding head machines while the company’s existing fixed head turning capability catered for parts up to 300mm diameter and 1.2 m between centres based on billets or sawn lengths of bar. This had the disadvantage of requiring continuous operator involvement.

However, he maintains their practicality and confidence in unmanned running was restricted to 32 mm bar diameter with the sliding head machines while the company’s existing fixed head turning capability catered for parts up to 300mm diameter and 1.2 m between centres based on billets or sawn lengths of bar. This had the disadvantage of requiring continuous operator involvement.

Added Warren May: “We could see the market changing with work coming back from overseas so we needed to be more cost-efficient otherwise we could be left behind. They decided to go to MACH 2016 and check out how to effectively expand their bar capacity for single operation production.

Said Stewart May: “We looked around the show with a complete open mind but were drawn back to the Citizen stand and the newly launched Miyano BNE-51MSY fixed head turn-mill centre. Its 51 mm bar capacity left us very positive about the way forward.”

For the first time, both directors decided to make their way to Citizen’s October Open House and seeing the same machine perform, placed the order. Said Stewart May: “From the day it was installed we have never looked back and it immediately made some of our second operation machines and equipment redundant.”

MTE was originally founded by the two brothers in 2002 specialising in very small batch work with two fixed head lathes and eventually adding up to nine cam autos to the plant list. They acquired a used Citizen E20 (sold as seen by a dealer) in 2004 which is still in production. Stewart May commented how it has produced hundreds of different jobs. “It will still hold 0.025 mm tolerances and surface finish throughout an eight hour shift. This impressive performance for an older machine”

Another early Citizen L20 produces the same component on a 20,000 a month contract alongside the only BSA cam auto still resident in the plant. Said Stewart May: “The BSA cannot be beaten on cycle time and although the Citizen is running at almost double the time, at the end of the day without any machine adjustments being made, twice as many Citizen made parts are in the finish bin. Most important, all are to size and without a single part-off pip that needs subsequent removal.”

As order books progressively grew, mostly from ‘word-of-mouth’ recommendations, plus added contracts from existing customers has brought its live customer base to some 80 firms. MTE had to move or add premises several times over the years as business grew and they ran out of space again before moving to the current site in 2012.

Commenting on the expansion, Warren May said: “ As the recession was biting in 2008 we felt we were becoming ‘Pooper Scoopers’ because as we were such a lean operation with low overheads, customers were flocking to our doors for quotes seeking reduced prices. As a result we picked up a lot of orders. In retrospect, we can see many of the parts were what competitors wanted to avoid, but it extended our customer base, helped us gain more expertise and led to future work helping us to be more profitable and especially as we introduce newer technologies.”

The current customer base covers automotive related including manufacture of special tools and spares for out of production classic vehicles, hydraulics, security, special fasteners, injection moulders petrochemical and medical sectors. As a result materials processed include, carbon and stainless steels, brass, Tufnol and phosphor bronze. Said Warren May: “We now see our new brewing customer drawing in further potential business.”

That said, Stewart May is firm on the future strategy of the business to keep growth under firm control and plan to be investment led, so as to improve profitability.

Now employing nine people, both Stewart and Warren are involved in setting machines as well as Stewart’s son Ashley who is an ex-production apprentice. While the head count is small, it is highly skilled and much of the work involves resetting machines for 75 per cent of repeat orders. Batch sizes on the Miyano, although early days is between 100 and 300 while each Citizen has varying batch sizes between 500 and 60,000. Most repeat orders involve machining for controlled stock holding which can extend the run time between settings and enables a fast response to customer delivery.

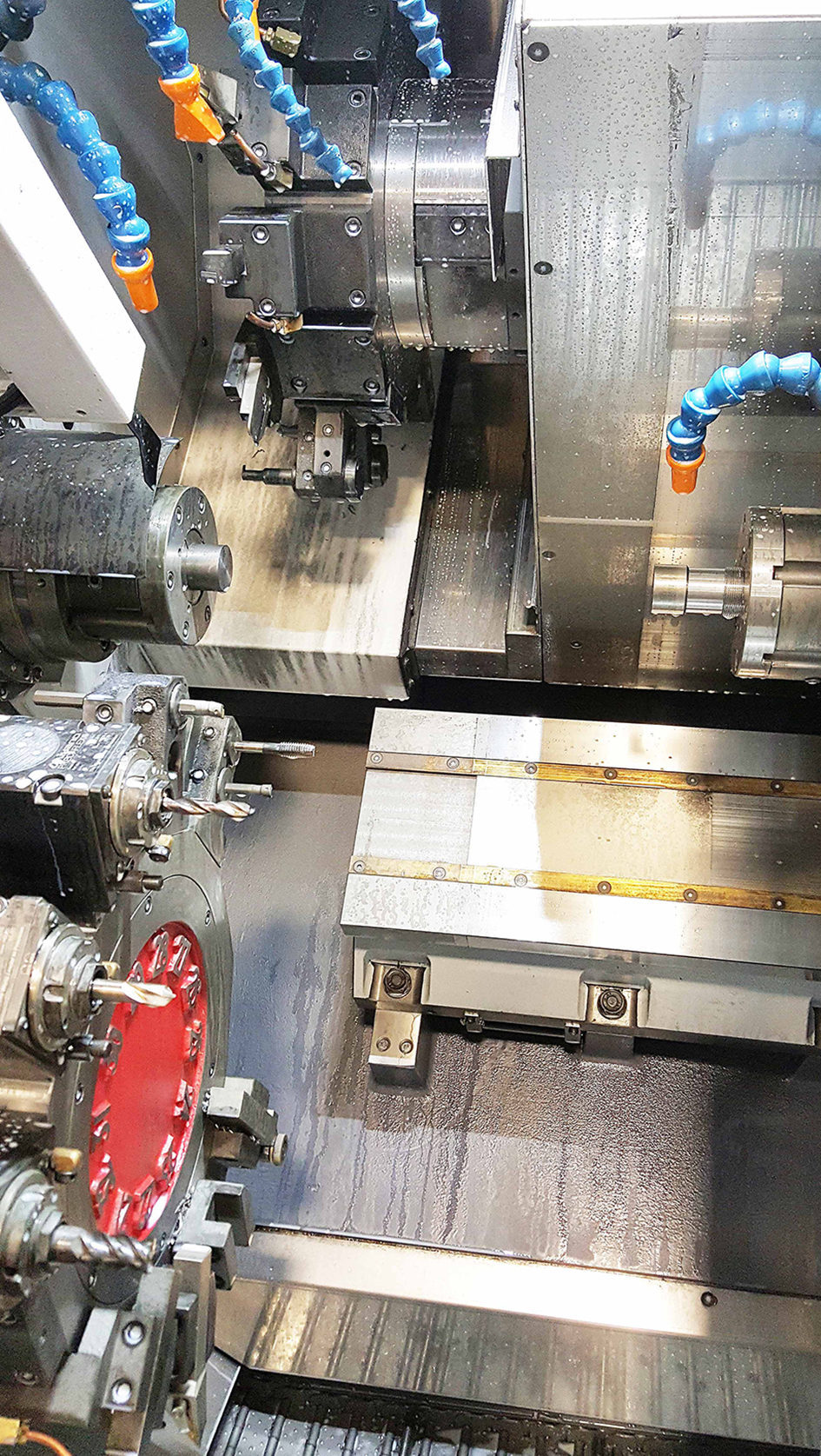

The 8-axis Miyano BNE-51MSY with IEMCA Kid 80 bar feed has created a massive advantage in lead time reduction for MTE due to the ability to overlap in a cycle and cut with up to three tools simultaneously. The machine has two 12-station driven turrets one with three axes, the other with two that can service either or both spindles at the same time.

The main spindle has a 15 kW drive and the secondary 2-axis spindle is powered by a 7.5 kW motor. Both spindles have a 51 mm capacity with a maximum speed of 5,000 revs/min. Each driven tool position is ideal for milling with a 2.2 kW high torque 25 Nm drive and programmable speed of 6,000 revs/min.

In producing the hydraulic body out of 38 mm bar, a 22 mm spade drill is used to a depth of 57 mm, then using a special flat bottom tool a face and corner relief is created at the bottom of the bore prior to final boring to 0.03 mm size. A further bore is then drilled and reamed 11.9 diameter to 0.03 mm tolerance by 76 mm deep and the initial bore threaded 1” x 20 TPI Whitworth by 8 mm deep. The OD is then turned and threaded 11/2” x 16 TPI Whitworth over 100 mm length.

The part is then taken by the 3-axis secondary spindle, faced and a 30 mm A/F hexagon milled by 20 mm long and a 6 mm shoulder created which is straight knurled. A through bore is then drilled to break into the 11.9 mm bore which is then tapped 7/16” x 20 TPI UNF by 26 mm deep.

Such are the productivity gains with the new machine at MTE that both directors are now reviewing other fixed head operations and especially the on-cost of the additional secondary machining tasks which could be dropped into single hit cycles.