The typical small machine shop and subcontract environment is always striving for maximum tooling performance whilst aiming to minimise inventory and costs. All this can now be achieved with the new Qplus range of high performance end mill tools from Tewkesbury based Quickgrind.

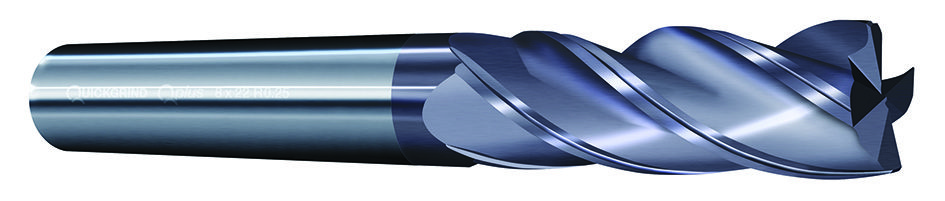

The new Qplus line of tools has been developed with the aim of creating the industry’s most universal tooling series yet. The four flute end mill generates remarkable performance levels on steel and cast iron whilst the hard wearing MX coating from Quickgrind makes the Qplus ideal for high temperature alloys, hardened steels and non-ferrous materials and also the subcontract environment.

Not only can the solid carbide Qplus series be applied to a diverse spectrum of materials, it can conduct anything from rough to finish machining, slotting, profiling, trochoidal milling and much more. The benefit of this seemingly endless diversity is that machine shops can use a single tool for a multitude of applications and materials. For the client, this reduces tooling costs and inventory requirements whilst eliminating the need for continuous tool changeovers. By reducing tool changeovers and the associated non-cutting times, end users can improve their cycle times significantly.

Further removing valuable time from the machining process is Quickgrind’s ingenious MX coating. The exceptional wear resistance, durability and toughness of both the MX coating and the sub-micrograin carbide substrate enable the Qplus to outperform alternate products on the most challenging of applications. Additionally, this substrate and coating composition combines with the tool geometry to dissipate heat from the cutting area, extending tool life immeasurably. The centre cutting tool geometry and the long flute length expedites the swarf from the cutting area with astounding speed to eliminate swarf build-up and re-cutting.

Available from stock as a standard item, the four flute Qplus is available in diameters of 3, 4, 5, 6, 8, 10, 12, 16 and 20mm with an extended flute length from 12 to 45mm. To enable the Qplus to conduct slot, side and pocket milling at depths beyond alternate products, Quickgrind has equipped the series with an extended neck of 20 to 22mm for the 3, 4 and 5mm diameter variants. The 6 to 20mm diameter tools incorporate a 0.25mm radius for reducing the risk of corner chipping and a straight shank design that generates increased rigidity, stability, making it the tool of choice for heavy duty cutting. The long reach end mills are available with an overall length of 58mm for the 3, 4 and 5mm tools whilst the 6 to 20mm diameter tools have an overall length from 58 to 105mm. As always with Quickgrind, they are more than happy to talk to customers about custom made tools to suit their application.