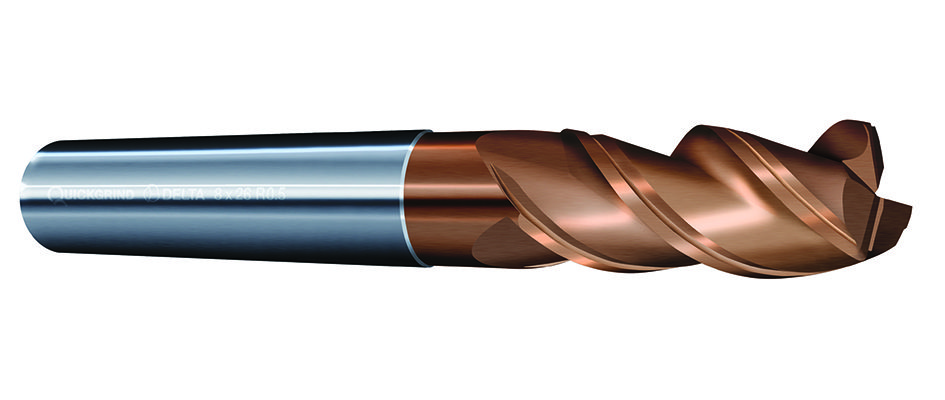

Quickgrind has been at the forefront of tool design and manufacture for over 50 years and this experience has been exhibited in the company’s latest line of three flute end mills, the Delta Series. The new high performance milling range has an extended reach; unique geometry and Quickgrind’s Xred coating that culminate in a high-performance end mill suitable of machining a vast array of materials.

The extended reach of the new solid carbide Delta end mill gives it versatility beyond competitor products whilst its submicron-grain carbide substrate generates unrelenting rigidity. This significantly extends tool life and performance levels. The Delta generates a smooth cutting action that is courtesy of its variable helix flute design and the centre cutting geometry that rapidly evacuates swarf and minimises vibration. The combination of an h6 ground shank, a rigid micro-grain composition and an innovative geometry deliver results with impeccable surface finishes, tool life and material removal rates.

Primarily suited to stainless steel and high temperature alloy machining, the durability of Delta series also enables clients to effectively apply the tools to a variety of materials that span from steel, cast iron, stainless steels, super alloys, hardened steels and much more. From an application perspective, the centre cutting geometry makes the Delta well suited to HSC strategic milling applications whilst the variable flute geometry excels on slotting operations. The general purpose end mill line is available with a square end or corner radius and it is offered in diameters of 3, 4, 5, 6, 8, 10, 12, 16 and 20mm.

The Delta is supplied with flute lengths from 10 to 38mm and with an extended neck length from 20 to 60mm depending upon the chosen diameter. This impressive flute and neck length allows users to reach further and machine deeper slots and pockets than alternate is complemented by an overall length of 58mm for the 3mm diameter variant through to 105mm for the 20mm end mill. As well as square end variants, the right hand cutting Delta is available with 0.25mm radii for the 3 to 6mm tools, a 0.5mm radius for the 8 to 16mm diameter tools and a 0.75mm radius on the largest 20mm diameter end mill. Quickgrind are happy to accommodate clients who require tools with other radii. For more details on how Quickgrind can improve your productivity and surface finishes whilst reducing your tooling costs and inventory levels, please contact Quickgrind.