JC Precision Engineering earns 70 per cent of its turnover from producing a wide range of components for racing go-carts, a business that has grown progressively from the race track participation of the Munday family led by father Vincent who set up the firm 36 years ago and is now run on a day-by-day basis by his two sons Dan and Chris.

Production at the Market Overton factory in Rutland is steeped in CNC machining centres and fixed head lathes for turning, for which around £1 million has been invested over the last five years, usually buying one machine a year. However, around the family table, discussions have often broached the subject following a visit to MACH 2014 at the NEC that perhaps they should invest in CNC sliding head turn-mill technology for producing smaller precision parts.

Said Director Dan Munday: “We used MACH 2016 as the final decider and ordered the Citizen Cincom L32-VIII with removable guide bush which was installed in July. Almost immediately we wondered why we had debated so long. Indeed, such has been the success of the machine already, that we are now planning for a second because we are becoming concerned we could run out of capacity.”

Since July, apart from more effectively switching work from other machines, the firm has won new contracts that they could never have dreamed of producing before. The directors have already noted how they have increased not only profitability, but also throughput, with cycles now being clocked two-thirds faster than before. For example one part taking 50 plus seconds on a fixed head machine is now produced in just 17 secs.

However, most important to them is that lead times are being decimated against previous methods which involved separate fixed head turning and often further milling and drilling set ups as well as manual finishing. Indeed, further benefits are also being accrued from the ability to achieve total consistency enabling ‘through-the-night’ running and the ability to maintain tolerances as tight as 10 micron when needed.

Stub axle shaft made from 31mm EN8 is machined with single cut to 17mm diameter and 0.025 tolerance on Citizen L32.Vlll at JC Precision Engineering.

As a result, previous production methods involving four or five set ups have been reduced to one including in-cycle deburring. Batches as small as 20 have proven to be economical especially when planned with other work with the machine already either set with or without the guide bush in place or having no need for a bar change. This economic capability for small quantities has also encouraged design input for certain key customers as well as development and providing a prototype service.

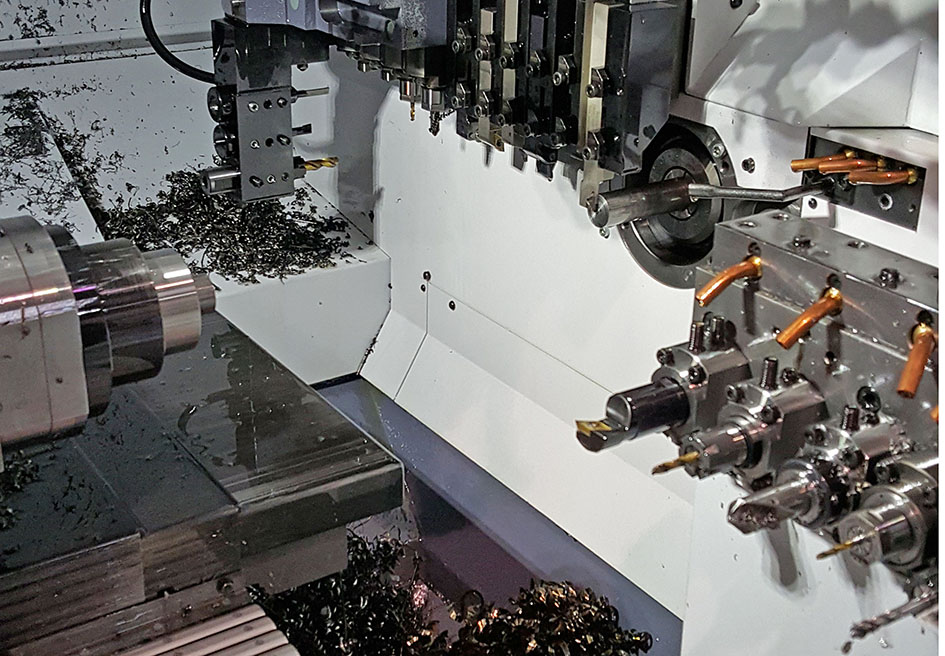

Citizen L32-Vlll with removable guide bush installed at JC Precision Engineering.

In ordering the Cincom L32-VIII the Munday’s elected to specify the detachable guide bush. Said Dan Munday: “We have considerable demands for special sizes of short length parts such as spacers and even washers where we can save on bar end material and it takes less than 30 minutes to change over to a guide bush when needed.”

One of the concerns holding back the venture into CNC sliding head technology was the different approach to the application when compared with more traditional CNC turning. But admits Dan Munday: “We had excellent support from Citizen which quickly convinced us how our worries were totally unfounded. What makes things easier is the Cincom control software plus Citizen’s AlKart CNC Wizard programming aid which certainly helped us to get up to speed very quickly.”

He describes how they are running a wide range of parts in materials including EN24, 316 stainless steel, plastics, aluminium and brass. These include special bolts and pins, master cylinder brake pistons, brass fuel fittings and stub axles. Indeed, a further point of disbelief in the capability of sliding head machining has also been dispelled in producing the stub axle out of 31 mm diameter EN8 when in a single cut of 7 mm, the part was taken down to 17 mm diameter and held to a 0.025 mm tolerance. The part was then threaded each end from the main and sub-spindle and within the cycle, a hexagon was milled adjacent to a flange.

JC Precision Engineering, which employs 15 people, acquired its premises in 2000 having a floor area of 1,000 m2 and is currently planning to add another building on the site. This will enable them to meet future demands and to install a second Citizen helping to increase turnover from the current £1 million from the karting sector as well as its more general sub-contract business.

As father Vince maintains: “The whole business has always maintained a steady growth and with the input into design, development and prototype activities, although this takes up valuable production time, it is paying massive dividends in customer loyalty and a longer term order book.”

The Cincom L32-VIII has five axes with a 40 tool capacity of which 15 can be driven. It has a 7.5 kW main and 3.7 kW sub-spindle each having a maximum speed of 8,000 revs/min. Driven tools are powered by a 1 kW, 6,000 revs/min motor. Of major importance, which is proving to be a key factor in the firm’s applications, is the ease of removal or replacement of the guide bush assembly from the main spindle to accommodate the machining of greater numbers of shorter parts from a bar.