Established over 60 years ago, the reputation of Ogle Models & Prototypes can be recognised from its customer list down the decades. Manufacturing special projects for Bentley, Virgin Atlantic, GSK, JLR and Lamborghini to name a few, some of the company’s early work includes the Y-fighter and Luke Skywalkers’ land cruiser from the original Star Wars film in 1976.

The company wins such prestigious projects through its skill set that includes expert model making and hand crafting, which is mixed with modern technology such as industrial 3D printing, vacuum casting and CNC machining. To keep abreast of technology, the Letchworth company recently purchased a FANUC ROBODRILL D21LiA5.

Delivered just over a year ago, the ROBODRILL has been an exceptional addition for the Hertfordshire business. Managing Director of Ogle Models & Prototypes, Mr Len Martin says: “We bought the ROBODRILL, because we are always on a quest to make things faster and with better quality, and what we currently have is a lot of other machines that are ordinary 3-axis CNC machines. These are basic machines and we wanted to move our business on and produce much higher quality parts at greater speed. It’s a drive for everyone to be more competitive and make parts quicker.”

As a business, Ogle Models only manufactures prototypes and small quantities. As Mr Martin says: “We don’t do production runs, it’s all one-off and small quantity work. Therefore, you could say production time is less relevant and it’s all down to programming. The new machine runs faster and produces a better finish than some of our existing machines, but even if we did have a small batch of 20-off, the FANUC is at least twice as fast as our other machines. Added to this, the quality and accuracy is also a huge factor.”

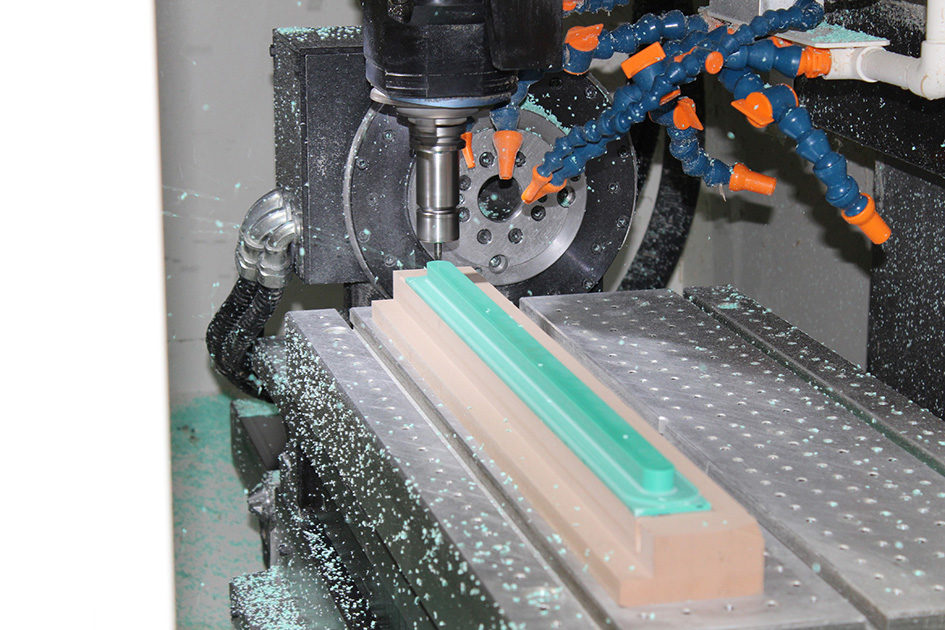

Primarily, the company uses model board on all its CNC machine tools. However, the FANUC ROBODRILL has been tasked with machining everything from model board through to plastic, aluminium and steel.

Demonstrating the productivity credentials of the FANUC D21LiA5, Mr Martin continues: “We undertook a project to make aluminium paddles for a car with plastic interior paddles, as the customer preferred the feel and look of a polished aluminium finish. We started by machining the job from solid aluminium billets on one of our older machines, but halfway through the job we took delivery of the new ROBODRILL. We then transferred the job to the FANUC ROBODRILL, and by doing this, the FANUC produced the paddles twice as fast with a far superior surface finish.”

When selecting the ROBODRILL, Ogle Models wanted the largest version of the machine available with a 4th axis configuration. “We wanted the largest possible work area as we knew we would lose some natural space with the 4th axis. We wanted all the hallmarks of an extremely fast machine with as big a bed as possible. The machine certainly hasn’t disappointed, it’s been a really impressive addition for us.”

Commenting upon the acquisition of the high powered FANUC ROBODRILL D21LiA5 at Ogle, Mr Ian Taylor, a Model Engineer says: “When I joined the company, it was a machine that I really wanted to work with, and I recommended it purely because of the large work envelope and small footprint. On top of this, the ROBODRILL is very easy to use. As a company that conducts most of its programming off-line, the CNC control is extremely easy to use when it comes to operating the machine. I’ve used a number of control units down the years, and the FANUC control is by far the most user friendly. We have to set up the job and the tool off-sets, and this is very straightforward to do, as the controller takes you through the process, making everything quite clear and easy.”

The BT30 ROBODRILL has a BBT spindle nose interface that provides exceptional speed, power and rigidity with its face and taper configuration. “We need this combination of attributes, as one day we could be machining a very soft material like model board or plastic, and the next day it could be aluminium, brass or even steel. I need a very big variety of options and the ROBODRILL gives us this, especially with the speed control feature that gives me complete control when it comes to operations, such as drilling or tapping, for instance.”

Ogle Engineers Inspecting Parts Machined on the ROBODRILL-1

“Very often, we do very long programs and run our machines unmanned overnight. It’s quite frequent that I will have a 16 hour machining job that will be set at the end of the shift to run unmanned overnight. With the 850 by 410mm table, I also have the facility to set up multiple parts, as a lot of the work we do is quite small. This means we can have a batch of parts produced overnight.”

The 21 tool position machine has a maximum spindle speed of 24,000rpm and Ogle utilises this speed capability frequently. As Mr Taylor continues: “We regularly use 0.25 or 0.5mm diameter cutting tools, and a lot of our more detailed work requires tools with a 0.1mm diameter. We run these small tools for fine detail features, such as graphics or engraving parts. With regards to machining at these high speeds, we have to run the tools at equally high feed rates. We have to remember that even though the tool is cutting, it is also rubbing against the part at the same time, so if I run the tool too slow it will get too hot. To this end, we run at very high feeds to get the swarf out of the flutes and away from the part as quickly and efficiently as possible.”

Demonstrating these high speeds and feeds, Ogle recently manufactured a series of parts from polyurethane model board at 20,000rpm with a feed of 8m/min. “This is as fast as we can run the machine on detailed parts, as they have curved edges and intricate features, and this means the machine has to decelerate and accelerate. In essence, the FANUC ROBODRILL gives me everything I need from a machine: it’s extremely fast, reliable, powerful and precise. Furthermore, it has a large bed with a 4th axis capability, which means that we can machine an extremely wide variety of parts on the FANUC at high speeds.”