Edgecam’s game-changing Waveform Roughing strategy is providing a solution to an issue of parts distorting, faced by a company manufacturing flight control components.

Aerospace specialists Produmax were having to leave components “to rest” for a week after roughing, as the process led to them bending. But Managing Director Jeremy Ridyard says when they started using Waveform milling to speed up cycle times and provide better swarf control, they discovered an added benefit: the components were being subjected to considerably less stress.

“Waveform generates only minimal heat, so we’re getting far less distortion, and the parts don’t bend anywhere near as much as they did. Which is especially valuable, as high precision is our major USP.”

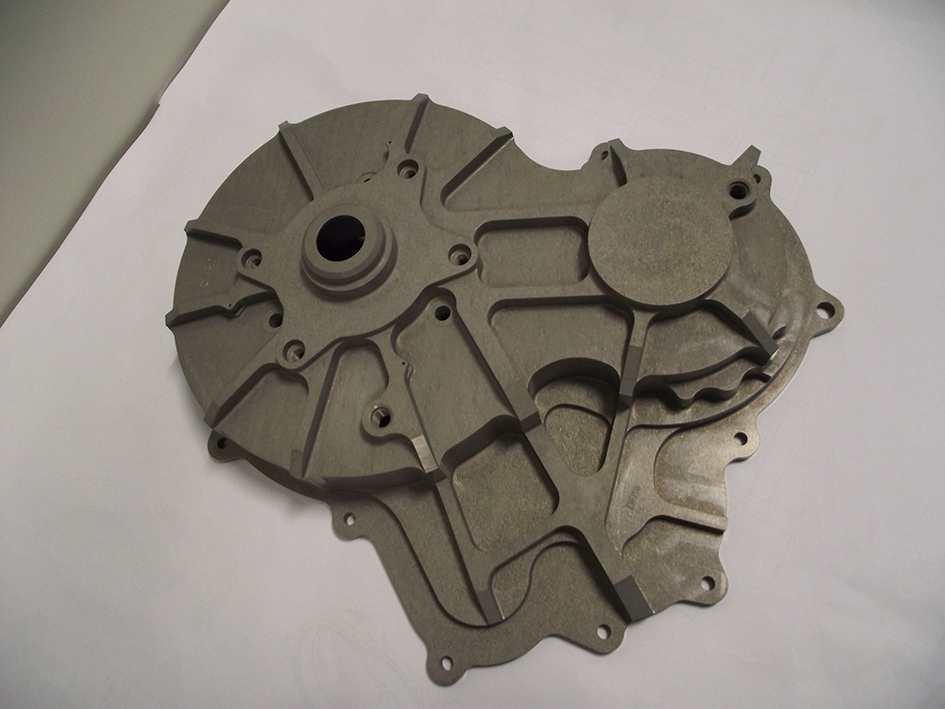

Edgecam, from Vero Software, drives their Mori Seiki, DMG and Nakamuura CNC machine tools, creating toolpaths for a wide range of components made from Titanium, Inconel and Aluminium, mainly for the working area of aircraft wings. This includes flaps, leading edge, steering mechanisms, rudders, and thrust reversers, along with bearings and bushes, and complete assemblies. They also produce a number of fuselage components.

“We always work to extremely tight tolerances, and produce some large gear box casings with a thou total run-out from milled surfaces to turned bores. Before we started using Waveform we had to hand lap the gear box faces to get them in position where we could go back and finish machining, because of the distortion. But with Waveform we’ve been able to take out all the lapping processes because we’re getting much better stability.”

The company also fully utilises the Waveform turning strategy, and plunge milling. He says Waveform turning is particularly important for swarf evacuation on components with deep grooves. “It allows the swarf to break readily, so the coolant can easily wash it out of the groove. Previously, the swarf was stringy and could clog the cutting tool, sometimes even breaking it. But using Waveform turning with button tools and double-sided grooving tools we can push it harder, improving the cycle time.” He says the turning strategy has been particularly successful in producing PH steel components around three-quarters of a metre long, requiring nearly 80 per cent metal removal.

“Waveform speeds up both milling and turning roughing operations by at least 30 per cent, and also gives us first rate swarf control, which is very important to us.”

And working with the Advanced Manufacturing Research Centre (AMRC), they came up with plunge milling as being the best process for producing PH steel thrust reverser door mechanisms. “Plunge milling profiles with a lot of stock, on a Mori Seiki MH40, rather than machining round profiles, gives us 40 per cent faster metal removal rates.”

He says the Mori Seiki’s sturdy Meehanite bed construction makes it the ideal machine tool for plunge milling. “Just working in the Z-axis, drilling the material out with an indexable insert, means we’re taking large radial stepover cuts which remove the material much faster. The swarf chips are smaller, and the process puts all the heat into the swarf instead of the component…so again, there’s less stress on the parts.”

They use Waveform mainly on internal cutting, with plunge milling largely reserved for external profiles.

Jeremy Ridyard says Waveform is also a critical part of their automation process. “We’ve recently installed a DMG NMV 3000 with 34 pallets, and we also run Laing Automation Eco towers. Using Waveform for swarf control, we’re currently hitting 60 hours of unmanned production on Saturday, Sunday and Sunday night. We just load it up with pallets and it runs right through the weekend.” They carried out trials at Mapal in Germany to prove out the Edgecam programs for the operation. “Mapal tested six different software programs for the roughing strategy, but the Waveform strategy beat their best cycle time.”

Produmax have never been shy of innovation and thinking outside the box. They describe themselves as “engineering superheroes,” a phrase coined when they began working with the Government-backed Sharing In Growth (SIG) scheme in the early days of their ongoing expansion, which has seen them move out of 9,000 square foot premises at Otley and 3,000 square feet at Leeds Bradford Airport – into a £3.1m purpose-built high-tech 28,000 square foot factory at Shipley, in West Yorkshire.

Utilising their five core values of Passion, Reliable, Dynamic, Freedom, and Ubuntu (a Swahili word used in this context to mean a bond of sharing – “It’s our word for Teamwork,” says Jeremy Ridyard), they are well on course for a turnover of £10m by 2020.

“We have a culture where we’ll try anything – we learn through designated experiments to push the boundaries in our production cells, and we’ve designed the factory with a separate division purely to practice new operations which can then be rolled out into the full manufacturing process.”