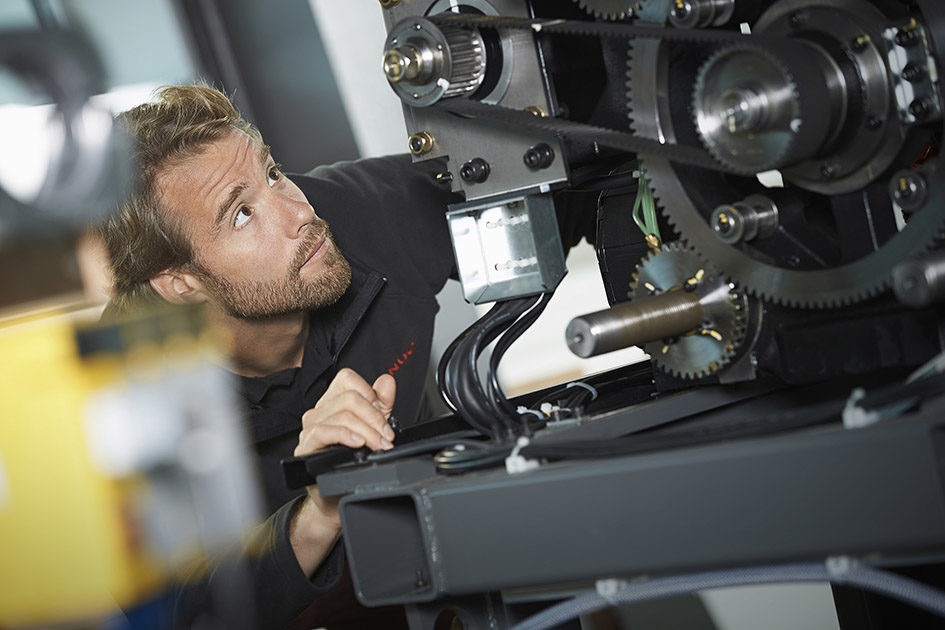

Gary Taylor, Service Manager RO FANUC UK, explains how preventative and predictive maintenance can be used to keep FANUC robots – and other automation equipment – at the peak of their powers.

Many manufacturers operate at high volumes, and unplanned production downtime is becoming more expensive and much more critical. When a production line goes down unexpectedly it can cost a company tens of thousands of pounds a minute.

Failure to provide regular robot maintenance can lead to issues including: position deviation, loss of repeatability, cable damage, outdated software, and even possible safety issues.

Often, these issues are discovered only after production downtime has occurred in a factory and only when a physical connection to the robot allowed for analysis and subsequent service. But by solving problems proactively, unexpected downtime can be prevented and the scheduled downtime is drastically reduced.

Preventative maintenance

Every robot needs preventative maintenance to ensure top-level performance and consistency on the production line. When robots do not have regular maintenance checks performed, parts and components may break down or malfunction, which can cause a slowdown or shutdown of production. Industrial robots that are properly maintained can last for many years, even decades, before needing to be replaced.

While planned maintenance may shut down production for a short time, it is nothing compared to the loss of production time if a robot stops working. Planned maintenance may also be scheduled around planned quiet time or holiday shutdown periods.

While FANUC provides robots with high reliability and uptime averaging over 80,000 hours mean time between failures (MTBF), and a typical robot working two or three shifts may be operational for up to 4000 hours per year, a recommended maintenance frequency should nonetheless be calculated on the basis of the operating time and nature of the duty cycle. This will typically be based on an annual programme of checks, but may be more frequent, depending on circumstances.

FANUC Robotics recommends that planned preventative maintenance should be performed as detailed in the robot manual. These routine service interval visits would be undertaken by one of its certified specialist maintenance technicians. However, recognising that a maintenance strategy must be suited to a user’s individual needs is essential, FANUC offers a wide range of standard and customised maintenance contracts. FANUC will also undertake the complete tear-down and rebuild of older robot models.

To minimise downtime in emergencies, a Corrective Services element can be added to the standard FANUC service agreements. This guarantees a fast response and that repair work is carried out quickly by local service engineers. Special 24/7 Breakdown Support agreements can also be combined with any of the standard Preventive Maintenance, Spare Parts, or Predictive Maintenance agreements.

It might be thought that almost every FANUC robot operational in the UK would be covered by a FANUC maintenance contract of some description. But in fact this is not the case. Many companies choose to service their own machines, or use a third party. Others may choose not to service their robots at all, instead taking the economic hit if and when something goes wrong. In such cases, FANUC recommends the strict use of OEM parts to ensure seamless compatibility between system components. Not all replacement parts on the market are reliable, and some are counterfeit and illegal!

Perhaps more surprisingly, there are many FANUC robots in operation throughout the country that FANUC does not know about, largely because of a thriving second-hand market. Unlike the sale of cars, where the DVLA keeps a record of every transaction, no such system applies in the case of robots. In addition, some large multinational companies buy their robots from a FANUC facility in a different country and then disperse them globally.

For those who, for whatever reason, are not benefitting from a FANUC UK Maintenance Contract, every FANUC robot comes with an extensive maintenance manual, covering all the procedures that need to be undertaken to keep the product in tip-top condition.

Scope of service

For those who do opt to take out a FANUC maintenance contract, some of the key checks that the company will take care of during a 15,360 hours service interval include:

- Test and replace RAM and APC batteries, if required – these are used to maintain the robot’s factory settings (to avoid the painful duty of recalibrating the robot)

- Replace and analyse the grease

- Check motors and servos

- Inspect of brake operation

- Backup the controller memory

- Monitor robot in regular motion, inspecting robot, teach pendant, harnesses and cables

- Check robot repeatability

- Listen for excessive audible vibration and noise

- Check cable connections, cooling fans, power supplies, safety equipment

A few specific checks are also recommended in the early months of an installation to make sure that the setup has been correct:

- Ventilation of the robot controller’s cooling fans – keep these clean for efficient air flow

- Cables must be free from severe kinks, pinch points, cuts or tears in the wire insulation, and terminations must be secure

- Retighten external main mounting bolts

- Check the end effector or end of arm tool and its mounting bolts or screws, tighten appropriately

In addition, daily and weekly rota housekeeping duties should be undertaken by the end-user, such as the following:

- Clean sensors and optics within the robot cell and visually check component parts for damage before daily operation

- Check for grease/oil leakage or exudation

- Clean chips and debris

Predictive maintenance

FANUC offers an after-sales service to take care of many servicing issues and also track the service status of a machine. This aids predicting potential failures and optimise the planning of servicing and spare parts.

Taking this a stage further, predictive maintenance can be used to precisely monitor the condition of automation equipment in order to determine when maintenance is warranted. This method of managing a machine over its lifetime reliably predicts breakdowns long before they can lead to downtime.

Predictive maintenance requires constant vigilance in order to be effective, ensuring that maintenance engineers know when it is the right time to (for example) grease bearings. This can be difficult, considering that many variables can determine how regularly oil needs changing. In order to reliably measure the quality of lubricating oil and grease, engineers must identify the quantities of external contamination and metal wear, as well as its general condition.

For troubleshooting and diagnostics, it is possible to connect to FANUC machines on the factory floor in real time. This will allow speedy resolution of issues such as servo alarms, showing the possible root cause, as well as a detailed hardware diagram highlighting the relevant parts. The service includes data monitoring of the machine’s performance over time and the machine’s performance history throughout its life cycle.

Zero Downtime (ZDT)

Now, in a new initiative to keep robots running productively and efficiently, FANUC has teamed up with Cisco, supplier of analytics and automation software, application networking services, and cloud and systems management, to construct a new, preventative maintenance capability for operational equipment, which can result in a dramatic reduction of unplanned production downtime.

This system is called FANUC Zero Downtime (ZDT) and can be installed on all new systems. It follows a pilot project at a major US automotive manufacturer. FANUC ZDT proactively detects and informs of impending problems before unexpected downtime occurs, allowing the maintenance issue to be addressed in a planned outage window.

FANUC is using Cisco’s InterCloud to securely collect and analyse data from each robot in a facility. The results from the analysis of the data can be used to enhance robot performance as well as highlight issues in the system. For example, FANUC ZDT would identify increasing levels of resistance experienced by the robot, indicating a problem with a joint or a tool interface.

Any such issues trigger a notice to be sent to all smart devices listed in the system’s contact portal. In addition, the warning is sent to FANUC, who maintenance team can then evaluate the warning, diagnose the issue, and, if appropriate, order parts or send a maintenance team.

Cisco is an industry leader in security and secure networks, so all data collected to analyse the robot performance is carefully protected. Machine builders and end-users can also embed Cisco switching, security and compute technologies directly in the machine itself – or in a factory-floor aggregation device.

FANUC ZDT also helps improve and optimise a system based on robotics. This includes items such as:

- Improving cycle time

- Reducing energy consumption

- Extending robot life

European repair facility

With 500 service engineers across Europe and more than 40 years’ experience, FANUC provides OEM-trained service people for all its product groups.

From its European headquarters in Echternach, Luxembourg, FANUC provides a full range of services to its 17 European subsidiaries, including European Sales and Service, Product Support and Parts and Repairs. Here is located the FANUC Repair Centre, offering a dedicated centralised repair service for the company’s parts and machines. It combines diagnostic knowhow with parts availability and specialist expertise.

Recently, as part of a EUR 900,000 refurbishment exercise, fast, efficient and locally available lifetime maintenance and repair for European customers from a Central European location has been extended. And to maximise parts availability across Europe, the Part Warehouse carries an extensive stock of new and remanufactured parts. These are available 24/7 via a comprehensive logistics network.