Investment in a replacement automatic panel bender would have been three times higher.

At the Telford factory of Proteus Switchgear, throughput of bent sheet metal components is just as high using a manually operated, CNC folding machine as it was when the company was using a fully automated panel bender.

Purchased through sole UK agent, Press & Shear, the manual FLEXIbend 73.30, an all-electric model built in Germany by RAS Reinhardt, took over from the automatic, hydraulically-actuated machine from another supplier in January 2016.

The new folding centre is providing not only equivalent productivity but also greater flexibility for bending small to medium batches of switchgear cabinet components. Typical runs are from 10- to 20-off and occasionally up to 50-off.

The machine also delivers improved bending precision, helped by its rigid construction and by a patented, intelligent crowning system whose sensors measure and compensate automatically for folding beam deflection. Positional accuracy is within ± 0.1 mm. There is no error at all in the bend angles, as they are checked manually after the first operation using a set square or template, allowing offset values to be entered into the control.

The occasional problem of hydraulic fluid leakage from the previous machine has been eliminated. As its pump no longer runs continuously throughout the day, energy consumption has been reduced substantially. The FLEXIbend, being all-electric, draws power only when it is in operation, apart from a miniscule amount needed for the control screen.

Economical investment

For over 25 years, Proteus Switchgear has specialised in the design, development and production of electrical switchgear for factories, universities, hospitals, offices, shops and houses. The Telford-based manufacturer offers standard and bespoke units that provide flexible, reliable, energy efficient power distribution solutions to architects, consultants and facilities managers worldwide.

Andy Roberts, the company’s CNC Programmer commented, “Our previous, automated folding machine was nearing the end of its useful life and to replace it would have cost €500,000. In contrast, the FLEXIbend was one-third of the price.

“We were concerned that, being a manual machine, it would not be able to keep up with production so we retained the automated machine for a while to work alongside it.

“However, we only used it two or three times in the first four months after delivery of the FLEXIbend, so we had it taken out. Automated machines are space-hungry, so it has freed a lot of factory space for other activities, such as material storage and assembly of our switchgear cabinets.”

The new machine has the added advantage of larger capacity, being able to bend material up to 3,200 mm, compared with 2,100 mm on the automated machine. Proteus Switchgear can now produce 2.5 metre-long frame sections and cover panels for its cabinets without resorting to a standard press brake, which is inconvenient when handling such large components.

The new folding machine provides more flexibility for production of smaller parts as well, as to hold down sheet during automated bending, a minimum area of 200 mm x 150 mm was required for the clamping tool. There is no such restriction with the FLEXIbend. Proteus Switchgear produces a lot of end plates that are 130 mm wide, which previously had to be bent less efficiently on press brakes.

Modular, quick-change tooling

Proteus Switchgear chose a J-shaped sheet support table configuration at the rear of the machine to improve access to the tooling and allow single-handed manipulation of heavy sheets.

Mr Roberts contrasted the use of the FLEXIbend with that of a press brake. He said the latter requires special tooling to produce, for example, a hemming bend or a radius bend. Such full-width tools are expensive to buy and are heavy, making exchanging them time-consuming, which in turn reduces productivity and profitability.

The manual folding machine, on the other hand, needs only two sets of standard, segmented tools in the upper beam to produce all of Proteus Switchgear’s parts. Even a radius bend can be produced by repeated hits with a sharp tool, a sequence that is worked out automatically by the RAS control software.

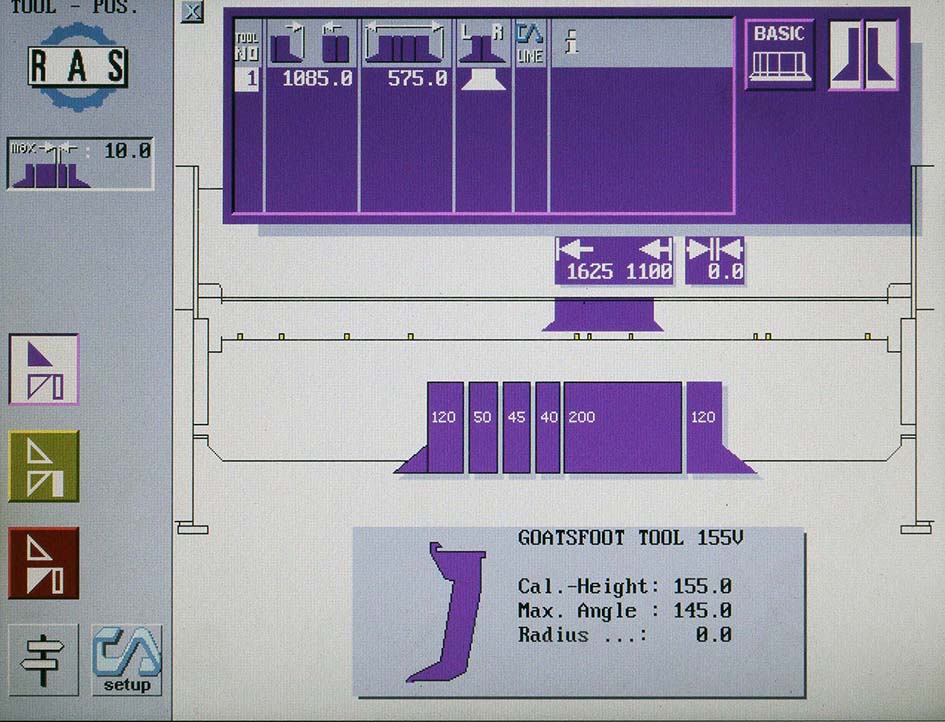

One set of tools, comprising mainly goatsfoot and sharp segments, is reserved for folding mild steel up to 2.5 mm thick. They remain on the machine for most of the time, as a majority of material at the Telford factory is between 0.9 and 1.5 mm. The other tool set is for producing components between 2.5 mm and 3 mm, which is the maximum thickness the machine can process. Swapping over the tools takes less than five minutes, as they are clamped automatically in the beam.

It is an easy matter to adjust the positions of the tool segments, each of which is up to 200 mm long, to create a number of sections along the length of the machine. The technique allows material of various widths to be folded at the different stations, without the part ever leaving the operator’s hands, avoiding unnecessary handling.

Machine and software

Set-up instructions on the control screen display the tool segments required for the length of the part. This information is available for the upper beam, the folding beam and the lower beam.

The design of the machine promotes ergonomic operation, as the operator does not have to push heavy sheets through from the front. Instead, they can be loaded from the rear using the integrated sheet support table and backgauge, which incorporates pop-up fingers that position the workpiece before each bend. Proteus Switchgear chose a J-shaped table configuration to improve access to the tooling and allow single-handed manipulation of heavy sheets.

After a program starts, a graphic on the control screen shows the operator which foot pedal needs to be pressed. The lower beam and the folding beam with their sets of segmented tooling automatically adjust within 10 seconds to suit the material thickness, whilst the backgauge positions the blank for the first bend. The folding beam moves at 90 degrees per second, resulting in high productivity.

Programming the machine is easy. It entails drawing the part on the control’s touch screen, after which software works out the bending sequence and simulates it, flagging up any potential collisions. Built-in technology tables take into account material springback. A 3D image of the finished part is displayed for verification before production starts.

On-screen instructions are provided for tooling adjustment, as well as details of which tooling segments are required to achieve the tool length the operator has programmed in. The information is stored with the folding program ready for convenient re-use.

Press & Shear also supplied Proteus Switchgear with RAS software for off-line, PC-based programming. Having an identical graphical user interface, it is especially useful when producing prototypes and special components required in ones and twos.