LPW Technology Ltd, a global market leader in developing, processing and supplying cutting-edge metal powder solutions for additive manufacturing (AM), has taken delivery of a new TRUMPF TruPrint 1000 metal AM machine. The first machine of its kind in the UK, the TruPrint 1000 will enhance LPW’s impressive AM R&D capabilities, centred at the company’s internationally recognised Daresbury Laboratories in Cheshire. For anyone interested in discussing either the TRUMPF machine or the capabilities it will offer LPW and its customers, both companies will be exhibiting at formnext 2016 in Frankfurt on 15-18 November.

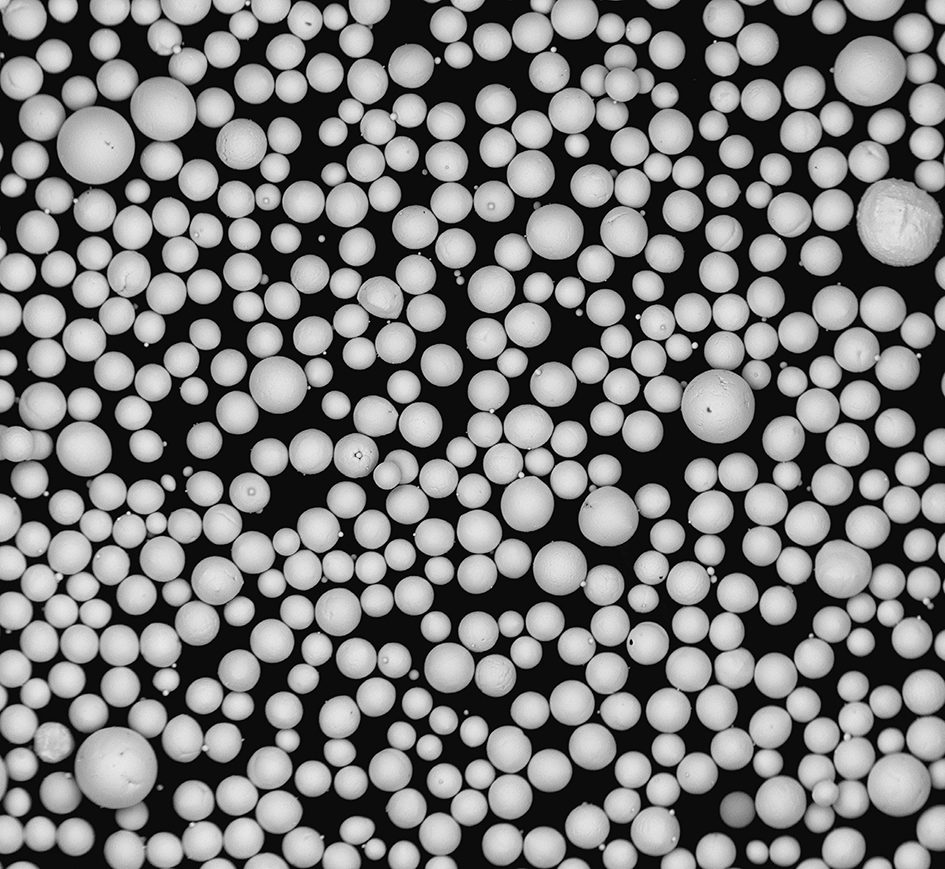

TRUMPF‘s TruPrint 1000 is a compact machine for the production of small metal components by laser melting on a powder bed. Also known as LMF (laser metal fusion), the process works by using metal powder and laser light, quickly producing components of virtually any geometric shape. This plug-and-play machine majors on intuitive operation, high process speeds, a generously proportioned process chamber and a complementary MobileControl App for remote operation and monitoring. The machine is expected to add important capability to LPW’s well-established metal powder expertise.

“LPW is expanding its PowderLife products and solutions throughout the industrial AM process and this new machine enables us to accelerate not only novel alloy development, but also applications testing, process optimisation, powder degradation studies and R&D projects,” says LPW’s Applications Manager Ian Brooks.

The TRUMPF TruPrint 1000 will form part of a new metal AM lab that is being created by LPW.