The Fine Pulse Technology concept has been announced by Walter Ewag UK, a member of the United Grinding Group, as an innovative erosion development that sets new standards in terms of PCD tool surface and cutting edge quality, as well as process reliability.

Being supplied as standard on all Walter Helitronic Power Diamond and Diamond Evolution two-in-one tool erosion and grinding machines, Fine Pulse Technology is the result of progressive improvements to the machines’ generator – which has been totally redesigned – as well as the erosion software. Enhancements have also been made to other machine design elements, Walter Ewag UK reports.

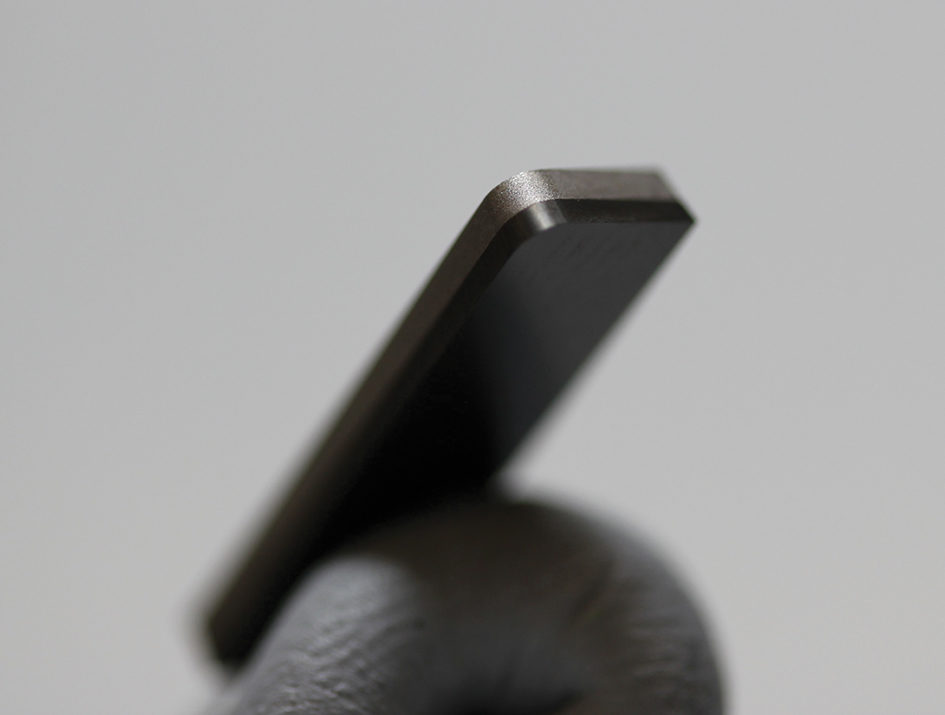

Marked differences to PCD tools of 10 microns grain type that have been eroded by other machines can be seen with the naked eye – the surface finish is like that of a polished (ground) tool – and even coarse-grained PCD types can be fine-finished with perfect surface qualities.

Now, with such super-fine finishes achievable on the Power Diamond and Diamond Evolution series machines, PCD tool providers can achieve superb levels of tool surface quality and cutting edge within similar processing times as before. Also, subsequent steps in production can even be eliminated because no re-sharpening or polishing is required.

Walter Ewag UK adds that the Fine Pulse Technology development is the result of Walter’s constant quest to ensure that its tool erosion concept meets the increasing demands being made on PCD tools in terms of quality and service life, as well as price and production time.

Walter’s Fine Pulse Technology sets new standards in terms of PCD tool surface and cutting edge quality, as well as process reliability.

Tel: 01926 485047

Email: neil.whittingham@walter-machines.de

www.walter-machines.com