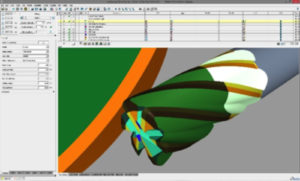

The latest version of the Walter Helitronic Tool Studio software for tool grinding now includes integrated functionality for the efficient and effective design, programming and simulation of PCD tool erosion.

Available from Walter Ewag UK, a member of the United Grinding Group, for all ‘two-in-one’ Walter Helitronic Power Diamond and Diamond Evolution tool grinding and erosion machines, the new Tool Studio Erosion Wizard-enabled software provides users with a quick and easy route to the selection and real-time simulation of PCD drill, mill and reamer production, and incorporates both the grinding and eroding operation.

After simply selecting tool size and geometry, then grinding wheel and electrode ‘package’, the system offers a simulation mode where parameters can be quickly and easily changed before tool production starts. The functionality also includes automatic collision control, and geometry and parameter selection for individual teeth.

The new software complements similar Tool Studio functionality for the wide range of tooling that can be produced/reground on the Walter range of Helitronic tool grinders. This ‘What you see is what you grind’ system has, in effect, now been expanded and enhanced to a market-leading ‘What you can grind, you can also erode’ package.

Stablemate to the larger-capacity Helitronic Power Diamond, the recently announced Helitronic Diamond Evolution is a revolutionary approach to the production and regrinding of PCD tools with diameters up to 165 mm and lengths of up to 185 mm (end face operation) and/or 255 mm (shank length).

The machine offers an unrivalled affordable and compact solution to the machining of complex PCD tools within this size envelope, which accounts for up to 90 per cent of PCD tooling consumption worldwide – including increasingly complex geometry PCD tooling in various forms such as solid tips, sintered spirals and PCD on diameters, as used for milling and reaming, and ‘straight’ PCD ‘plates’ and chamfered PCD tips for drilling.

Occupying a floorspace of just 4.2 m², the 9 kW/10,500 revs/min Helitronic Diamond Evolution can grind and erode a wide range of carbide and PCD styles including shank, profile, circular and roll mills, multi-step tools and countersinks, as well as cutting and profile cutting plates.

Its PCD tool programming routines include the erosion of PCD on tool diameters and the production of K-Land, variable spiral and ball nose gash.

In addition to a robot loader that can boost automation (unmanned) operation by automatically handling up to 72 HSK tools or 7,500 cylindrical tools (diameter-dependent), the machine also features an HSK spindle which, being shorter than an NCT spindle, offers excellent stability and superb electrode surface quality during dressing, as well as longer life for the dressing insert.

In addition to a robot loader that can boost automation (unmanned) operation by automatically handling up to 72 HSK tools or 7,500 cylindrical tools (diameter-dependent), the machine also features an HSK spindle which, being shorter than an NCT spindle, offers excellent stability and superb electrode surface quality during dressing, as well as longer life for the dressing insert.

The machine is also equipped as standard with Diamond Plus software that in addition to simplifying and speeding up the programming of complex PCD forms also enables production times to be reduced by up to 40 per cent and cutting edge quality to be improved (edge chipping down to just five microns at 10 micron grain size).

Walter’s Helitronic Tool Studio software for tool grinding now includes integrated functionality for the efficient and effective design, programming and simulation of PCD tool erosion on the company’s ‘two-in-one’ machines, including the Diamond Evolution