Workholding equipment supplier, 1st Machine Tool Accessories – www.1mta.com – has provided tombstones with quick-acting, versatile clamping fixtures for six of the 10 pallets in an Okuma flexible machining cell (FMC) at control valve and marine steering system manufacturer, Hydraulic Projects (Hy-Pro). In addition, 1st MTA has equipped two original tombstones with heavy duty, rapid workpiece clamping devices to minimise set-up times.

The hydraulic equipment manufacturer’s website – www.hypro.co.uk – displays a caption that reads: “Machining 95 per cent of our own components gives us control, flexibility and economy.” It also gives the company a large requirement for efficient ways of clamping its valves and pumps during manufacture.

A hallmark of the horizontal-spindle FMC at the Dawlish, Devon factory is the sheer diversity of workholding systems employed in the cell, made possible by the extensive variety of equipment offered by 1st MTA and also by the ingenuity of Hy-Pro’s engineers. They have designed and machined in-house additional fixtures that dovetail neatly with the elements that have been bought in.

On both cast iron tombstones at Dawlish, which are devoted to machining cast iron, hydraulic spool valves, 1st MTA supplied OK-Vise serrated, expanding clamps that provide even heavier duty workholding than Chick and Mitee-Bite solutions. Here, tightening each pair of clamps secures a pair of components simultaneously.

The rationale for populating the FMC with bespoke, multi-component fixtures dedicated to product families is to keep the Okuma spindle running virtually continuously during manned and unmanned shifts, producing economically any batch size from one-offs to 100s.

To this end, the machine was supplied with a 218-tool magazine, so cutters are exchanged only when they are worn, eliminating the need for tool set-ups when starting a new batch. Workpiece set-up is carried out off-line at a station in the pallet pool guarding, so the spindle waits only for as long as it takes to deliver a pallet to the machine and rotate it into the working area.

The first two 400 mm pallets had already been equipped with cast iron tombstones, for which bespoke support blocks were machined by another Okuma customer in the Midlands prior to delivery of the FMC to Dawlish. For retrofitting onto these tombstones, 1st MTA supplied 32 heavy duty, expanding clamping elements from Finnish firm, OK-VISE – www.1mta.com/ok-vise. On one pallet, each serrated clamp on every face secures one component against a fixed jaw, while on the other pallet, tightening a pair of central clamps fixtures two parts simultaneously.

Machining of two types of hydraulic spool valve from iron castings is completed in two operations on this pair of pallets, 16 of each type coming off complete per cycle. Hy-Pro’s machine shop manager, Kevin Saunders, advised that one operator previously produced 32 valves per day shift, whereas the number has doubled in the FMC, as it is run unmanned into the night.

Shortly after the FMC was commissioned in November 2015, its next four pallets were fitted with US-made Multi-Lok System 5 columns from Chick – www.1mta.com/chick-system5-multi-loks, one of 1st MTA’s sole agency product lines. The four faces of each column have either a Chick faceplate to which bespoke, multiple clamping fixtures are attached, or a Qwik-Lok fixture with machinable soft jaws and strong pull-down action for clamping two larger parts simultaneously when the handle is turned. Sometimes, especially when holding castings, the latter clamping action is augmented by the addition of Chick gripper inserts tilted to match the draft angle of the casting to ensure maximum grip.

For one of the faceplates, 1st MTA supplied compact Uniforce clamps produced by another US company, Mitee-Bite – www.1mta.com/mitee-bite-products, which expand in two directions to hold a pair of components simultaneously against fixed rails. Each steel wedge spreads the clamping force uniformly on both sides. Again, speed of set-up and component load / unload is the aim, ensuring that the pallet pool is always replenished.

Within six months of production starting, two further pallets were equipped with tombstones, this time from Abbott in the US, supplied through1st MTA – www.1mta.com/abbott-tooling-columns. Traditional in style, they differ from the others on site by being made from a cast aluminium, self-ageing alloy called Tenzaloy, said to have similar damping properties to cast iron. Mr Saunders was initially doubtful of the claim, but has since been convinced, as positional tolerances of ± 25 µm are held easily on machined features of components mounted even at the top of the Abbott tombstones.

An advantage of the lighter weight, aluminium alloy columns is that there is scope for fixturing a greater number of heavy components without reaching maximum pallet load, which in the case of the Okuma machining centre is 400 kg. One of the cast iron tombstones was recently very close to this limit when fully loaded with fixtures and components.

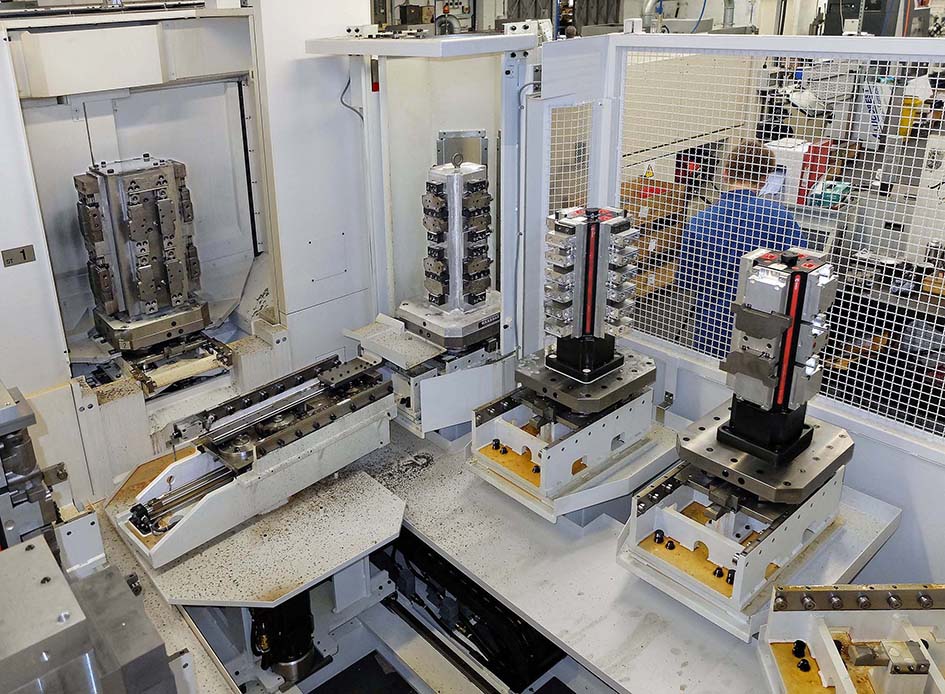

Another view of the Okuma FMC pallet pool, showing one of the cast iron tombstones in the machine ready for pallet exchange equipped with OK-Vise heavy duty, expanding clamps. An Abbott Tenzaloy tombstone is in the load/unload station. To the right are two Chick tooling columns with faceplates and, far right, Qwik-Lok twin-station, fast-acting jaws.

Another Mitee-Bite product supplied by 1st MTA augments the Abbott tombstones, namely Pitbull clamps with two tool steel knife edges in a top rail and another in a bottom support rail that grip securely into the faces of iron castings. The low-profile workholding units, which were easy to configure with bespoke fixtures made in-house by Hy-Pro, provide maximum access for the tool to the workpiece for flexibility of machining.

Now that eight of the 10 pallets in the FMC have been populated with highly efficient workholding fixtures on the various styles of tooling column, the eight- or nine-hour manned shift is supplemented every day with unattended machining up to around 1.00 am, giving 16 hours of production in every 24. Mr Saunders predicts that, when fixtures have been made for the two remaining pallets, production will be extended to 22 hours per day.

He mentioned that 1st MTA has also assisted the turning department at Dawlish by providing a workholding solution for turning an aluminium cylinder end cap. An Abbott pie-jaw chuck – www.1mta.com/pie-jaws – has been supplied that fits into the counter spindle of the Colchester lathe so that the component’s outside diameter and internal profile can be turned in one hit. It is a second operation, the first being on a machining centre; the main spindle of the Colchester lathe is not involved.

For the same machine, when it is used as a twin-spindle lathe, the pie jaw is replaced by a Kitagawa QCRL42 collet chuck supplied with requisite adapter plate – www.1mta.com/collet-chucks, the Japanese manufacturer being another principal for which 1st MTA acts as sales agent in the UK. Mr Saunders prefers the collet design to a standard jaw chuck, as he says it allows higher accuracy of machined components and is easier to use, as the inconvenience of having to set and bore out chuck jaws is avoided.

He concluded, “We have to control manufacturing costs closely to compete with low-wage countries, so we need efficient machine tools allied to similar workholding practices.

“By dedicating each tombstone to machining families of parts and configuring fixtures to hold them securely and quickly, we believe that we have achieved the ideal set-up for in-house manufacture.

“1st MTA has done a good job providing us with consultancy over the past year, helping us to develop optimal workpiece clamping across eight of the 10 pallets in our Okuma cell.

“The supplier offers such a vast range of products that it was almost inevitable it would have a workholding solution to suit all of the components we manufacture.”