Presented with the opportunity of supplying sawing equipment that would drastically reduce cutting times of even the very hardest stainless steel materials whilst simultaneously extending blade life, Prosaw rose to the challenge and after extensive research, developed a startling new sawing system.

Established in 1987, Sheffield based A.D.Bird Stainless Ltd. supply specialist stainless steel materials and products ranging from precision ground shafting for use in the marine, petro-chemical and automotive industries, to an extensive range of cut blanks.

The company specialises in stainless steel bars of up to 12 metres in length and 640mm in diameter, depending on the grade, including conditioned grades such as Precipitation hardened stainless steel.

Prosaw’s challenge was to design a sawing system that would overcome these tough criteria whilst simultaneously maximising the efficiency of the cutting process of not only those grades previously deemed difficult or near impossible to cut, but of all grades of stainless steel.

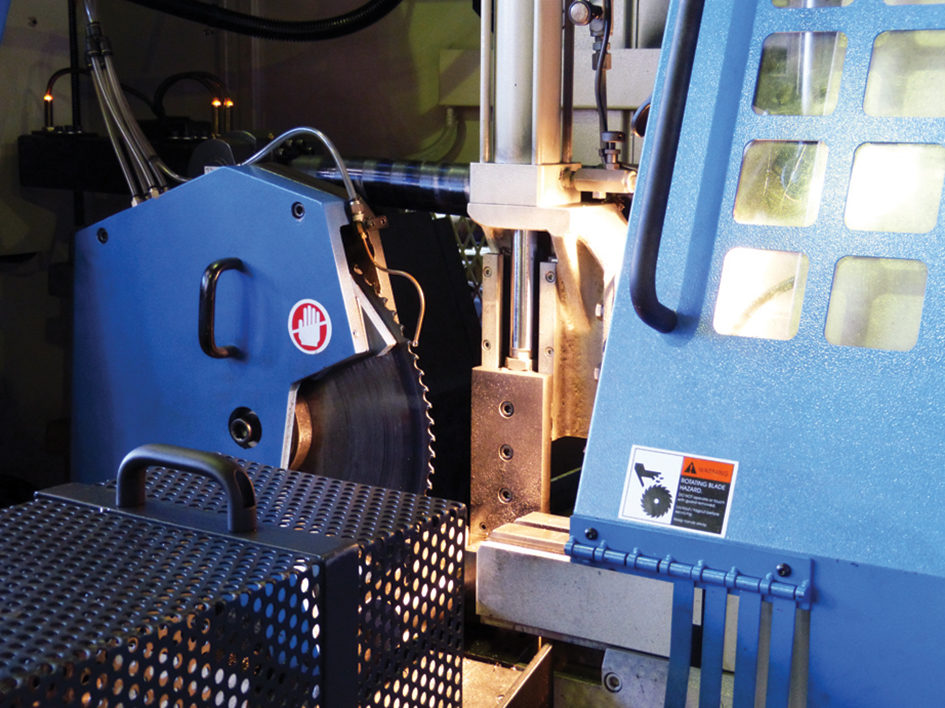

After exhaustive research and development followed by comprehensive cutting trials with the manufacturers, Prosaw were satisfied that they had developed a solution to the challenges that they were faced with, by producing a purpose-built new model Mega CS-150SN circular carbide machine that features lower cutting speeds but with a greatly increased torque than is normally available.

Explained A.D.Bird Stainless Ltd’s Managing Director Nigel Bird, “Cutting times are now that much shorter than before, so much so that the Prosaw CS N machine has made several of our older machines redundant due to the capacity and speed of the new machine.” Adding: “Our overall experience has been very good indeed and when any minor problems have arisen, they have been swiftly solved by Prosaw.”

Tel:01536410999

Email: sales@prosaw.co.uk

www.prosaw.co.uk