Fabrication specialist Hydram Engineering has invested £2 million in two automated sheet metalworking cells at its factory in Chilton, County Durham. One is an automated CNC punching cell with integrated, 23-shelf tower store for material, which entered service in July 2016. The other, supplied as a turnkey system by Bystronic UK and commissioned in September 2016, comprises two of the Swiss manufacturer’s flat-bed, fibre laser cutting machines fed automatically with sheet from a Remmert bespoke six-tower storage and retrieval system.

This year’s spend by Hydram follows substantial investment throughout 2014 and 2015, during which the business introduced a panel bender, a second automated paint plant, a third robotic welding facility, a shot blasting machine, an eighth power press and a tenth press brake, whilst adding a further 20 per cent of space to its 100,000 sq ft factory.

In addition, further floor area has been freed due to the fibre laser cutting cell’s 30 per cent smaller footprint compared with that of the former laser cutting facility, which involved a pair of Bystronic CO2 laser machines and manually accessed, cantilever racking for sheet material. One Bystronic CO2 laser cutting centre remains on site, a 4.4 kW model with a ByTrans Xtended material handling system, installed in 2012.

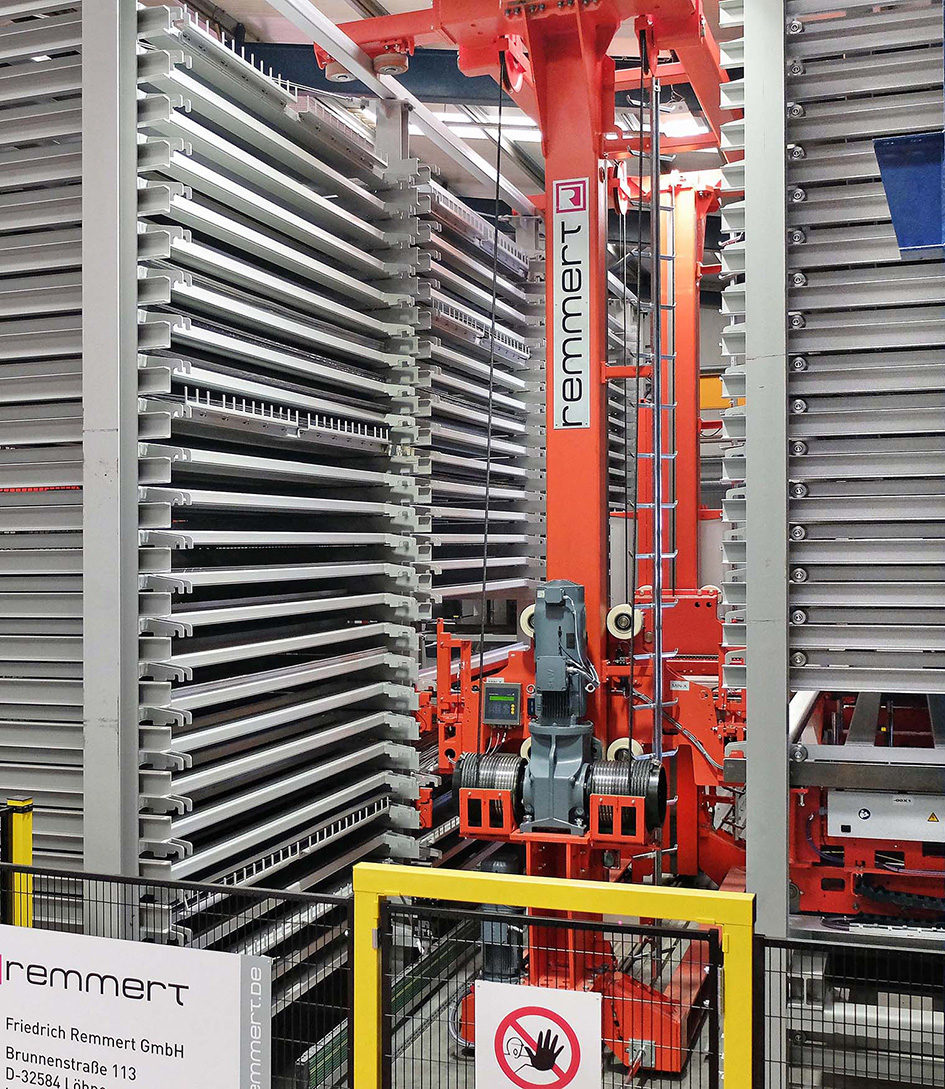

Sheet metal being delivered to the input station of the Remmert tower storage system feeding the Bystronic fibre laser cutting centres at Hydram’s Chilton, County Durham factory

Founded in 1977, Hydram has offered subcontract laser cutting for nearly 20 years as part of its services and is now one of the largest metal fabricators in the UK. In addition to precision sheet metalworking, the privately owned company offers tubular metalworking, welding, powder coating and assembly. Customers include such leading OEMs as JCB, Mitsubishi Electric, Caterpillar, Ideal, Herman Miller and Alexander Dennis.

Most recently, the subcontractor was selected by Hitachi Rail Europe as a key supplier of sheet metal assemblies for the £5.7 billion Intercity Express Project. The multi-million pound contract is for the supply of metal hand poles, painted interior panels, bracketry and assemblies for the interiors of 866 carriages for the Great Western and East Coast Main Lines.

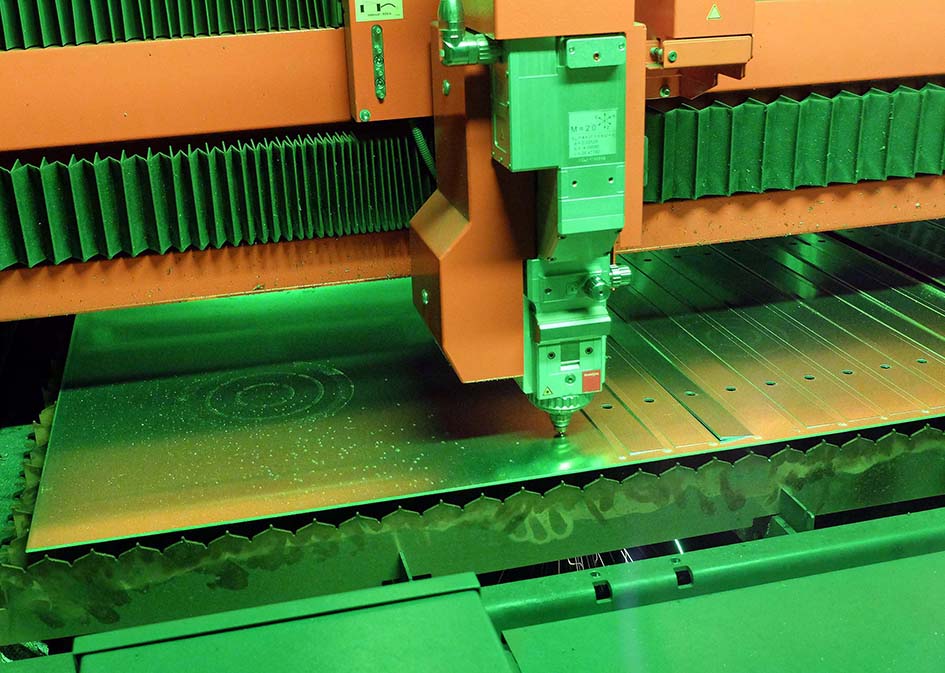

The material arrives at one of the two BySprint Fiber 3015s via its ByTrans automated handling station. Here a sheet is ready to be placed onto the machine’s shuttle table before entering the laser cutting area.

Hydram’s managing director David Greatorex said, “Against a background of strong business growth, we decided to upgrade and automate our sheet metal processing to improve manufacturing efficiency.

“It will help us to keep down production costs and increase our competitiveness in the global marketplace, which is important as most of our customers are multinationals that can choose from suppliers internationally.

“Our customers demand flexibility, high quality and keen pricing. The investments we continue to make year after year help us to meet, if not exceed, their expectations.

“We had automated punching and laser cutting in our sights for several years and with hindsight we should have moved ahead with it sooner, as the benefits are so far-reaching.”

Andrew Jordan, the company’s systems and technical manager explained, “A major advantage of automated supply of sheet metal to our Bystronic machines is that we have been able to do away with three fork lift trucks that were previously needed to take pallets of material to the buffer stations.

“To service the fibre laser cutting cell, we now only need one lift truck in the goods-in area to load sheet onto the Remmert input station. Manning levels are therefore reduced, added to which one operator can run both laser machines, whereas two were needed before to attend their CO2 predecessors. I estimate that labour costs are 30 per cent lower than previously.

“Our health and safety manager tells us that fork lift truck movements are the biggest single risk factor in our factory and any reduction in their use is welcome. It is therefore a bonus that we have been able to reduce their use and enhance the safety of our personnel as well as our machinery and materials.”

Due to the speed and reliability with which material is delivered on receipt of requests from the operator of the two new Bystronic BySprint Fiber 3015 4kW machines, sheet metal component productivity has been increased significantly at the Chilton factory. There is minimal idle time while the integrated ByTrans sheet handling systems wait for the next pack of sheet to arrive from the tower.

The store has 120 shelves each carrying up to three tonnes of material from 0.8 mm to 6 mm thick, or previously cut nests awaiting unloading for production. Around half of the aluminium, mild steel, Zintec and stainless steel that is held on site is now accommodated in the Remmert system. The remainder is in the punch press tower or stored conventionally and can be up to 20 mm thick.

Laser cutting in one of the BySprint Fiber 3015s.

A nest of components is cut from a 3,000 mm x 1,500 mm sheet on a BySprint Fiber 3015 in an average cycle time of eight minutes at Hydram. Commencement of the cycle is speeded by Bystronic’s Detection Eye feature, which recognises sheet position on the table in seven seconds by scanning it using a camera mounted on the cutting bridge. ByObserver is also fitted to both machines to enable remote monitoring from a mobile phone or PC from any location.

A spin-off advantage of the fibre laser cell is that it avoids the previous issue of fork lift trucks having to transport pallets of material down a steep ramp or around the outside of the building to the former CO2 laser machines, which were 1.5 metres below the level of the goods-in area, as are the fibre machines. Potential conflict between material movement around the punch presses and the fibre laser cutting centres is also avoided now that both cells are equipped with automated sheet handling.

David Larcombe, managing director of Bystronic UK commented, “The fibre laser cell together with the Remmert storage system at Hydram is a superb installation. You would have thought the factory was built around the manufacturing cell, as every metre of space is used to the full.

Fibre laser cutting has been a great investment for many manufacturers in the UK, as it offers cutting speeds typically two to three times faster than on machines like those that Hydram replaced. Power consumption is around 60 per cent lower than with CO2 lasers and servicing and consumable costs are also dramatically reduced.”

Mr Greatorex concluded, “We have taken a long-term view to secure our future with this latest round of investment. The automated sheet metal processing cells have upskilled the activities of our workforce and raised productivity.

“They have also reduced the labour cost content of component manufacture through the ability to run overnight with minimal supervision and by drastically reducing manual movement of material. It saves double-handling and ensures that we get the most out of the machines.

“We feel that fibre technology has matured to a level where we are confident in its benefits over CO2, which we have been using exclusively until recently. With both fibre and CO2 lasers on site, we are able to take advantage of the best of both technologies.”