The 2017 release of the world’s most powerful sheetmetal CAD/CAM software, Radan, paves the way for the most exciting developments in the software’s history.

Product Manager Olaf Körner says: “We are on the verge of reorganising how manufacturers will be using Radan in future, and important updates to Radmanager in the new edition are the first steps towards this.”

Developers are working on separating Radan into two distinct aspects; first, traditionally creating NC code to drive CNC machines, and second, what they call “engineering of parts.”

Radmanager’s strength is that it creates nests without the user necessarily needing to know where the parts come from, what the order numbers are, or which customer they are for.

“But to achieve this, it relies on the parts being completely ready for nesting,” says Olaf Körner. “And that means more than just having flat parts with the right geometry. We need to know as much as possible about the parts – whether they can be cut on any machine tool, and the cycle times for all of those solutions. For example, it may be feasible to cut a part on either a laser or water jet, but while it would take only minutes on the laser, it may take two hours on the water jet.

“In Radan 2017, Radmanager’s ability to manage both 2D and 3D engineering of parts is the precursor to the entirely new forthcoming engineering system for any type of parts, including 5-axis laser-cut sheet metal, tubes, flat, and bent.”

The forthcoming Radquote, which is now available as a preview will be demonstrated at exhibitions and pilot customer sites ahead of its official launch. Radquote will also rely on engineered parts.

“This 3D engineering of parts is becoming increasingly important. It will enable manufacturers to break assemblies down from CAD systems, into their constituent components, and fully understand everything about them.”

2D CAD files can also be imported automatically into Radmanager now, without the need to convert them.

CAD/CAM Updates:

Radan 2017 addresses danger of scrap flying off, sliding under the sheet, or damaging the tools on punching machines, by flagging up where floating scrap will occur.

The Automatic Order Style Editor now shows graphically what the program is going to do, enabling users to home in on a particular operation to make changes. This is seen as a major improvement on the previous text-based system.

Still with punch presses, Radan 2017 configures machine tools with all available cutting tools, so that new customers have commonly used tools immediately available.

3D:

A side panel was introduced in a previous version of Radan which aids navigation around complex assemblies, but there was still a need to travel between the two. A new facility in Radan 2017 allows the user to stay with the model, and to immediately switch between front view, side view, top view etc.

The graphics drawing has been speeded up. As an example, Olaf Körner explains that in earlier releases, deleting all screws in an assembly may take a while after they were selected, but now he says the software will always deliver a quick and consistent frame rate. The 3D function also supports modern graphics cards more efficiently, improving performance on tablets.

The process of updating information between Radbend and Radan 3D has now been automated. “A design is analysed in Radbend, and then the bend information it provides fed back into the 3D model. This used to be a process that the user performed in a number of steps. Now, once the part has been identified, it’s a simple mouse click to update the information.”

Nesting:

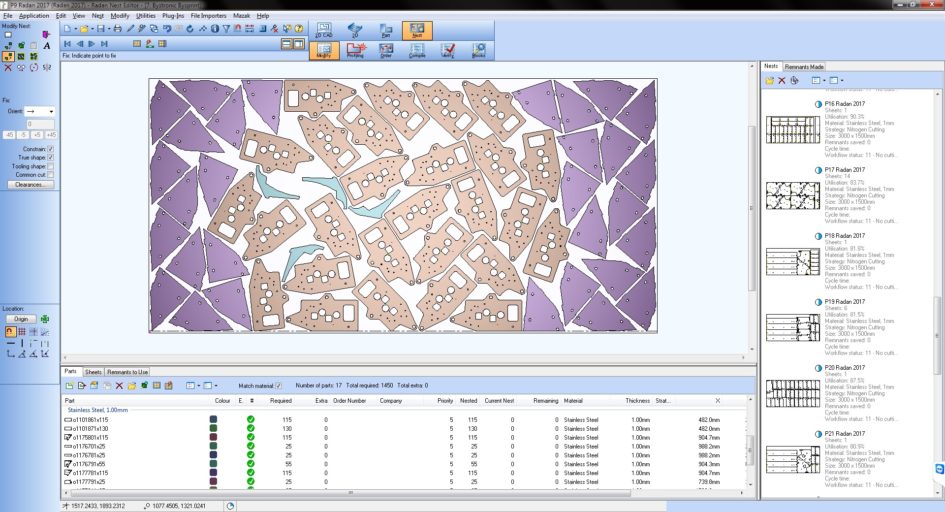

Improved algorithms have led to an important enhancement of Radan’s powerful nesting capabilities. “Continuous effort is applied to further strengthen the nesting engine to achieve a better fit, and therefore, a potentially better material yield.”

With an increasing number of users adopting project nesting, a new reporting engine ensures users can easily customise the content and design of their reports.

It is also easier now to create nest projects, thanks to the new template function. Olaf Körner says: “Existing project settings can be stored with a given name, and recalled at any time. “Even creating nest projects for the same machine tool sometimes required repetitive work, but now everything the user needs will be there, saving quite a number of steps.”

Profiling:

Autotooling routines are now more efficient in placing tags, or microjoints, for common cutting.

And the foil cutting function has been extended to scrap, ensuring that where sheets are covered with a protective foil for laser cutting, clean cuts can be made for scrap, too.

Radbend:

Radbend now highlights where holes are at risk of deforming by being close to bends.

Also, the operator can switch between Design and Result Values. “This is particularly valuable where Radbend shows the end result of a radius, for example, may be different from how it’s designed. Selecting which values gives the user more control over the finished bend, depending on whether it’s vital that they stay with the design values, or if the end result values are acceptable.”

For the first time, the user can now check with different maximum allowed force for the pre-bend and the hemming operation done with same tools.

Improved communication between 3D and 2D parts ensures that Radbend can now link to the 2D flatblanks created by Radan 3D. It also means that with more information going to the flatblank, 2D bends can easily be seen – the tooling and sequence number, as well as the radius, angle and setback.

Also, Radbend now supports the new user interface, Touchpoint TruBend, which combines the advantages of multi-touch technology with industrial control…as all Trumpf pressbrakes will move to this state-of-the-art controller.

Radtube:

While Radtube has traditionally been used for simply cutting tubes, it can also program any extruded shape for tube cutters, including I-beams, H-beams and C-beams, along with L-shaped profiles. “Because cutting a round or square tube is completely different from working with more complex beams and profiles, we’ve assisted the user with this by vastly improving automation and support.”

Summing up Radan 2017, Olaf Körner says the items of new and enhanced functionality provide immediate improvements for sheet metal manufacturers, while underlining the intention to continue investing heavily in the software.

“Developing Radan to engineer and fully analyse parts in this way is the biggest step forward we’ve ever taken. The future is very exciting, as the level of automation we’ll be able to achieve is phenomenal.”