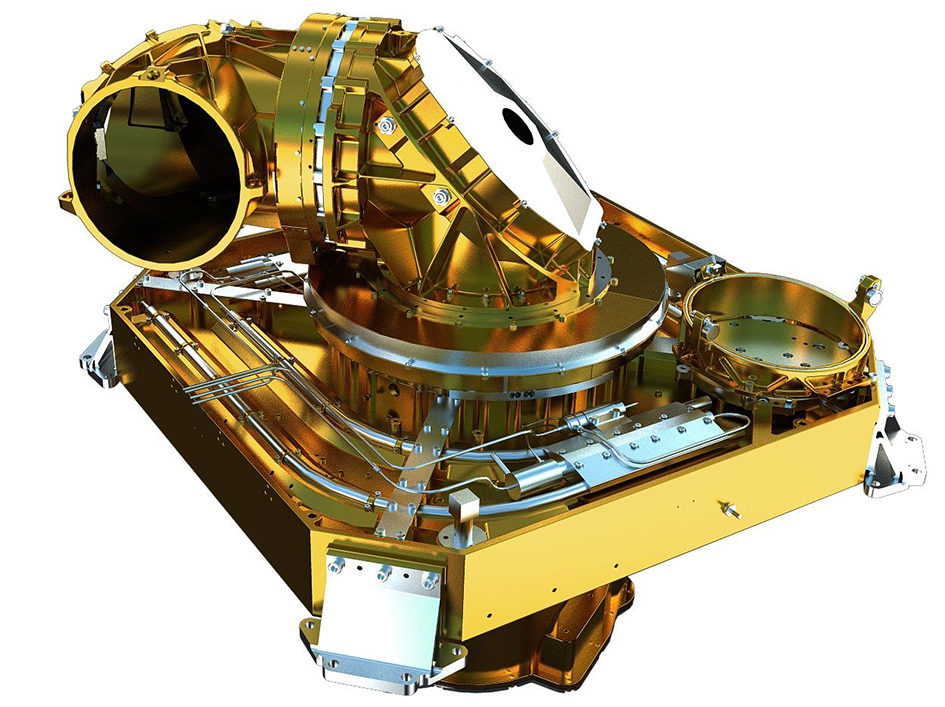

As mission-critical functionality goes, products manufactured by ExoTec Precision don’t come any higher on the list.

ExoTec are one of only a few companies in the world working with the rare exotic material, Beryllium, and their high quality optical lenses are currently deployed on a number of satellites. They also have components on their way to Mars as part of the ExoMars programme, including the Schiaparelli landing craft.

Beryllium’s unique properties of being the lightest machineable metal in the periodic table, along with its exceptional stiffness and outstanding thermal conductivity make it ideal for space applications.

ExoTec’s satellite-based products enable a range of functions, from Earth scanning to Laser Communication Systems. While NASA and the European Space Agency keep track of the space vehicles containing ExoTec’s products, the Somerset-based company rely on the Javelin production control system from Vero Software to ensure full material traceability on Earth.

Operations Manager Adrian Willoughby says one Javelin function in particular – Materials Control – gives them the ability to trace the component right back to the original billet it was machined from.

“With everything we order, we register the goods received note and record all traceability data associated with that material, so whenever we subsequently book material for a job we can maintain traceability from the original supplier, along with all their certifications. When we come to ship the finished product we can guarantee the exact origin of that material to our customers, which is particularly valuable for pure Beryllium and the other exotic and unusual metals we work with, such as AlBeMet and Aluminium Silicon Carbide.”

They have recently moved across from an old version of Javelin’s predecessor, Jobshop, to embrace the new and improved functionality, and Javelin now provides them with a simple, fast and efficient way of receiving orders, capturing and structuring the associated bills of materials, generating materials requirements and work instructions, and then launching works orders through the shop floor. It is also of paramount importance in putting them in complete control of their complex and sophisticated manufacturing processes, giving them the full traceability demanded by the aerospace industry.

As well as their ISO 9001:2000 certification which requires full control over their processes and documentation, ExoTec are one of the first companies in the UK to be working towards ISO 9001:2015 accreditations, and he says Javelin is playing a huge role in ensuring a successful audit at the end of 2016.

“A key part of ISO 9001 is saying what we do and then doing what we say, and Javelin gives us the structure in our processes to demonstrate full traceability and conformity to meet the standard.”

While relying on a number of Javelin’s powerful functions, he says it is particularly flexible in how its MRP aspect is used in conjunction with the Kanban system ExoTec operates. “Normally Kanban and MRP would be diametrically opposed approaches, but we still need Javelin’s MRP to give us a long-term forecast, while Kanban pulls the product through the line.”

Two of the most important items of functionality for them are Works Orders and Shop Floor Data Capture. With the WO function forming Javelin’s core element, it controls the progress of work through the manufacturing facility. A full set of monitoring and tracking routines ensures complete visibility of all Work In Progress. They also operate what Adrian Willoughby calls a “separate sideline system,” producing work instruction sheets. “Then we bring the two together, which tells the shop floor exactly what they need to manufacture.”

Javelin controls all their production processes, which include milling, turning, drilling, wire EDM, lapping, plating, polishing and vacuum coating. Depending on the individual products, the end-to-end process on the shop floor can have anything between 30 and 100 different operations, and ExoTec have SFDC monitors set up in seven areas of the factory to track the progress of Works Orders.

“We tend to capture at the end of each work centre to say that particular part of the job has been completed, then the work instruction moves on to the next step.”

As well as the satellite products, ExoTec also produces high specification mirrors for laser beam steering, required in applications such as laser welding, additive layer manufacturing, and equipment where lasers are used for cutting cardboard boxes and labels.Their products even steer the lasers used in for laser light shows. And while each component has to be absolutely perfect for those Earth-bound applications, ultra-precision and absolute integrity of parts used on spacecraft cannot be emphasised enough.

“In terms of mission-critical functionality, if our product doesn’t work it would mean the satellite doesn’t work, and the mission would fail. Javelin ensures we can guarantee the absolute integrity of the material we use and helps us get our processes right first time every time, so we can be sure every component has gone through all the correct manufacturing operations.”

ExoTec Precision: http://www.exotecprecision.com

Javelin: http://www.javelin-mrp.com