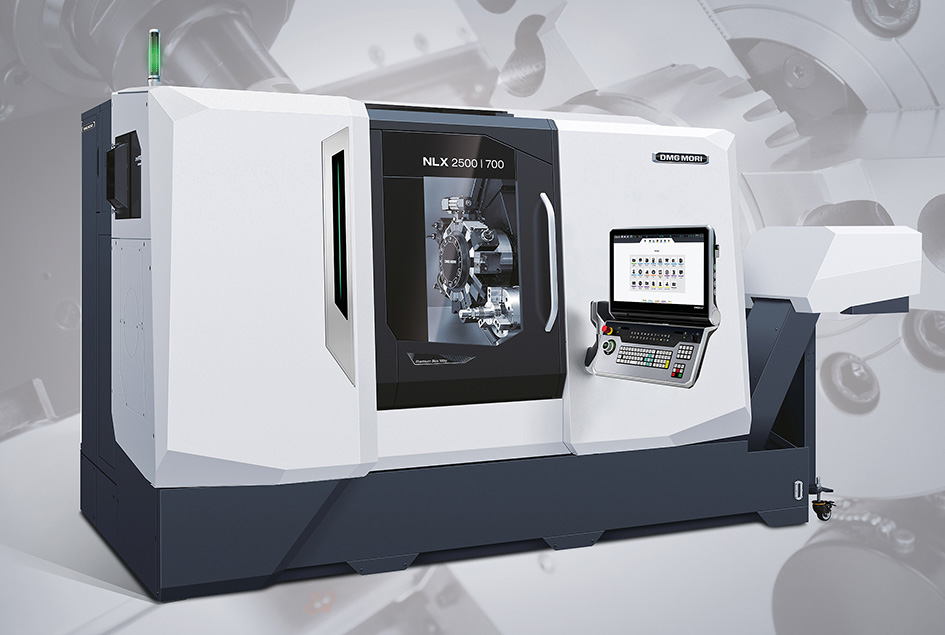

At the AMB 2024 exhibition in Stuttgart from 10th to 14th September, machine tool manufacturer DMG Mori will launch several new products. One will be the NLX 2500-700 2nd Generation turning centre, which is now available with the company’s own CELOS X app-based user interface on a Siemens Sinumerik ONE control.

Improvements have been made to the stability of the lathe and hence the precision with which parts can be machined. A pair of opposed, high-torque turnMASTER spindles, a maximum turning diameter of 366 mm and a turning length of up to 705 mm enable productive, heavy-duty machining of a wide range of demanding workpieces. Bar capacity has been increased to 105 mm diameter on both spindles, compared with 80 mm on the previous generation. A ±60 mm Y-axis is provided for off-centre milling, drilling and other processes.

The NLX 2500|700 2nd Generation twin-spindle, Y-axis turning centre.

In the area of prismatic machining, DMG Mori will introduce the DMU 85 monoBLOCK 2nd Generation. It combines the proven concept of the previous 5-axis machining centre series with optimisations resulting from customer feedback. Machining accuracy has been raised by the introduction of improved cooling as well as direct-drive ballscrews, which enable positioning accuracy to within five microns.

Workpieces up to 1,040 mm in diameter by 590 mm tall and weighing up to 1.5 tonnes can be accommodated. The integration of additional machining processes such as turning and grinding, the availability of automation options, and CELOS X as the basis for digitalised production, all render the machine a versatile production platform.

An extensive variety of spindle options is available, including speedMASTER spindles with speeds of up to 30,000 rpm for achieving high surface finishes or high-torque powerMASTER spindles with up to 430 Nm of torque for heavy-duty machining of titanium, for example.

The PH-AMR 750 automated guided vehicle for autonomous pallet handling.

Following the success of DMG Mori’s PH-AMR range of driverless transport systems for transferring pallets autonomously around a factory floor, from a store to machining centres and back again, the company will launch a further model, the smallest PH-AMR 750. It uses the same laser scanning system for navigating safely and reliably in the presence of staff. Integration into the manufacturer’s Cell Controller LPS 4 provides simple production planning and control.

Capable of being retrofitted into an existing production environment, the PH-AMR 750 is designed for carrying conventional machine pallets up to 630 x 630 mm, or zero-point workholding systems. Total maximum load is 750 kg and component size is up to 800 x 800 mm. The unit has two levels, allowing it to retrieve a pallet with a machined workpiece and deliver a fresh pallet with fixtured raw material in a single visit to a machine.

Leave a Reply