The success of tooling specialist OSG UK continues apace, with the company recently installing another Walter Helitronic tool grinder to meet rising monthly volumes of tool regrinds, orders for new tooling and to satisfy plans for its latest range of carbide tooling. These tools have joined the company’s own-brand series of high-class, cost-competitive taps, thread mills and end mills, as well as drills and reamers, and are set to be distributed throughout Europe via OSG’s European stock centre.

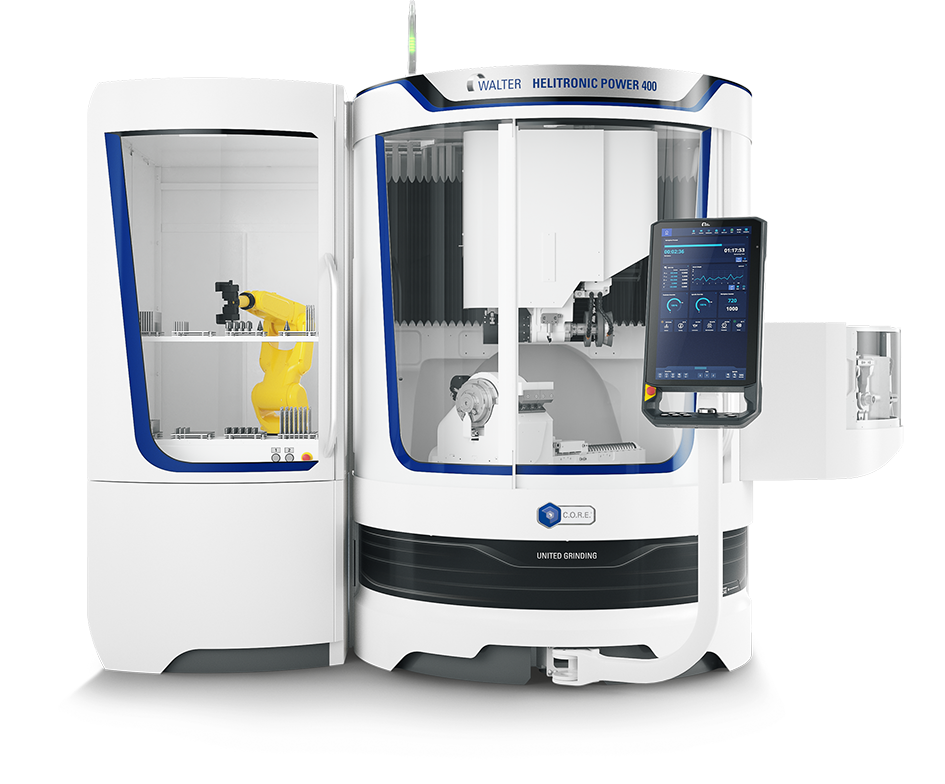

Supplied by Walter Ewag UK the company’s latest Walter Helitronic – a Power 400 – joins OSG‘s Basildon site’s existing Helitronic tool grinders and Helicheck Pro tool measuring machine, which complement the Helitronic machines in situ at OSG Nuneaton. The ongoing investment by OSG means the company is “superbly equipped to meet all current and immediate future demands,“ says Director Tony Cooper.

Importantly, the fact that all of OSG’s Helitronics have pallet systems and robot loaders means that variable size batches of tools can be pre-loaded and effectively and efficiently processed overnight, unmanned, in batches of up to 30-off to provide the ultimate in order responsiveness for a wide customer base including aerospace and automotive clients throughout the UK, Ireland and Europe.

With an eight-station wheel changer boosting flexibility even further the latest machine, the Helitronic Power 400, has says Mr Cooper been installed to meet ever-increasing orders for new tooling as well as regrinds – mainly of own-brand tooling – which now extend to several thousands every month.

The multi-axis Helitronic Power 400 features a mineral cast machine bed and gantry design, and it provides 26 kW (up to 24,000 revs/min) of spindle power. Coupled with sophisticated drive technology plus X, Y and Z axes travels of 650 mm, 350 mm and 720 mm, respectively, the machine can handle tools of 3 mm to 315 mm diameter, up to 520 mm long and weighing up to 50 kgs.

The machine features the Helitronic Tool Studio ‘grind what you see’ easy-to-use, wizard-based software, and its robot loader can accommodate tools up to 125 mm diameter and weighing 5 kgs.

Helitronic tool grinders are installed throughout OSG’s global operations based on the group’s worldwide technical relationship with Walter and the Power 400 joins the Walter machines at Basildon, where there is an integrated cell comprising Vision tool grinder and Helicheck Pro inspection machine.

The four-axis Helicheck Pro has a repeatability of +/- one micron and a measuring resolution of 0.25 micron, and it can accommodate tools measuring 200 mm diameter by 300 mm long. The machine is linked with the Vision for immediate feedback of measurement data and, where appropriate, real-time corrective action.

“Repeatability is everything when it comes to regrinding,” adds Mr Cooper. “So, it is essential that the right machining technology is operated by suitably skilled operators to ensure that the reground tool matches the customers’ demands exactly. Our strength as OSG is that we have access to all our original geometries, which means when we regrind tools we can get back to 100 per cent tool life – at least that is always our aim. Indeed, we are confident that in many cases our regrinds are even better than many other alternative originals.”

OSG UK’s continual progression – it moved into a refurbished 25,000 ft base in Nuneaton in 2021 a few years after acquiring PN Tools and currently employs 50 people across its two sites – also depends heavily on its ability to immediately supply a comprehensive range of cost-competitive tooling from an extensive in-house stock. Orders for standard tools taken up to 5pm are despatched on the same day.

Leave a Reply