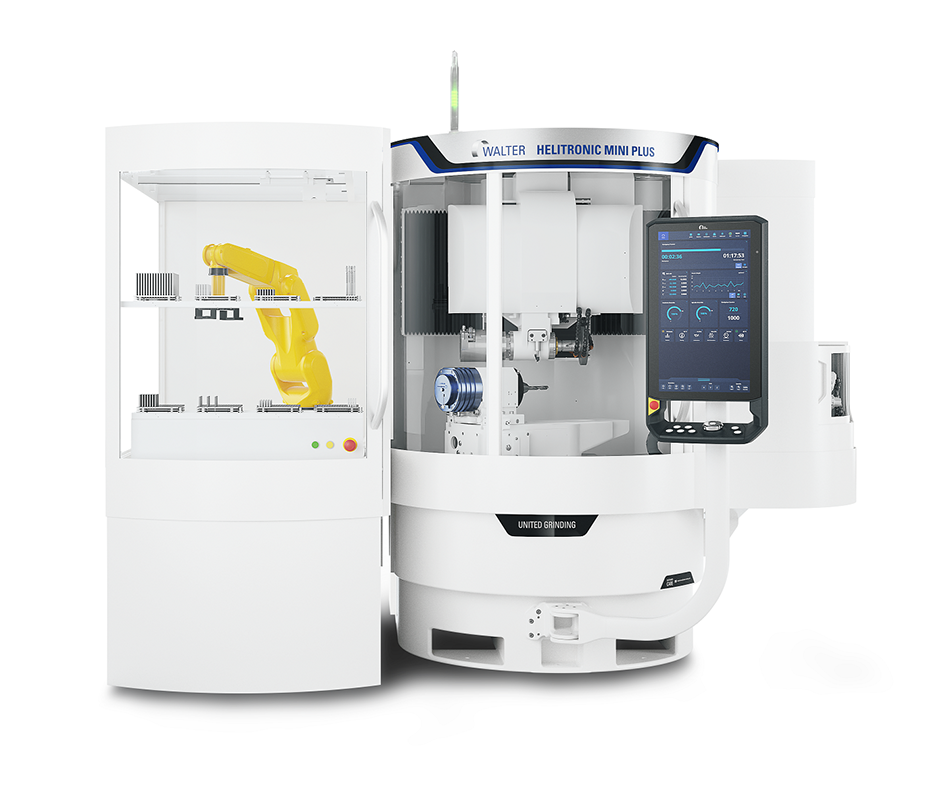

Two cost-effective Walter Helitronic tool grinders will make their UK debuts this summer when Walter Ewag UK stages an open house at its Warwick headquarters on June 27-29.

The Helitronic Mini Plus and the Helitronic G 200 represent the most affordable – yet very capable and highly accurate – models in the comprehensive range of tool and insert grinding, erosion and laser machines available from Walter Ewag UK. Both machines are designed for processing tools up to 125 mm diameter and both can utilise optional technology to capitalise on the rewards of increased automation.

In addition to showcasing the capabilities of these machines, the three-day open house will, says Sales Director & General Manager Phil Morris, also be staging daily workshops/demonstrations of a series of Walter’s money-saving and user-friendly operation tool production and regrinding, as well as inspection technologies, including the:

[] Rewards of integrated measuring;

[] Benefits of non-contact Laser Contour checking;

[] Use of remote network monitoring via Digital Services developed by parent company, United Grinding, plus

[] How the powerful yet easy-to-use Helitronic Tool Studio software can simplify and speed up grinding/erosion times.

Helitronic Tool Studio will be demonstrated at the open house on both the Helitronic G 200 and the Helitronic Mini Plus.

The latter can be used as a cost-effective ‘basic’ machine or as a fully automated model for the effective and efficient production of tools from 1 to 16 mm diameter, machining even complex geometries in a single clamping. The machine has a tool regrinding capability of up to 125 mm diameter.

A basic machine can be configured with a wide range of efficiency options and various loading systems, extending to become a fully-equipped ‘high-end’ tool grinder capable of all current and future applications in the small and medium tool diameter range.

The basis for the extraordinary flexibility of the Helitronic Mini Plus is Walter’s unique gantry design where the economical production of geometries in a single set-up is guaranteed by a powerful HSK belt spindle with two spindle ends for up to six grinding wheels (as standard).

In addition, the revolutionary C.O.R.E. (Customer Oriented REvolution) hardware and software architecture embraces the digital age by having intuitive operation that facilitates machine set-up, operation, networking and maintenance.

The options available for the machine – for application-specific application – include an automatic grinding wheel changer for up to six wheel holders (maximum diameter 152.4 mm) including coolant supply to ensure a safe wheel set change and maximum flexibility. In addition, for machines so equipped, a ‘torque increase’ option raises torque and removal rates by up to 60% for maximum productivity.

For automated use, users can choose between a Top Loader or Robot Loader, with the latter accommodating up to 7,500 tools, depending on the type of tools or tool diameter – maximum tool weight is 5 kgs and maximum diameter is 125 mm.

Integrated into the workspace, Top Loader is a space-saving and cost-effective solution and, depending on tool diameter, offers up to 500 tool locations; the loader is suitable for tools of 3 mm to 16 mm diameter and, for example, can accommodate 500 tools of 3 mm diameter on its Walter-standard robot pallets.

Top Loader is also the automated tool magazine of choice for the Helitronic G 200, a compact unit with a footprint of less than 2.3 m2 and a machine designed for processing tools up to 125 mm diameter.

With a maximum grinding wheel diameter of 150 mm, the Helitronic G 200 features a low-vibration solid mineral cast bed and is of C-frame construction that offers high damping capabilities and temperature stability, resulting in maximum precision in grinding.

Its X, Y and Z linear axes mirror Walter’s renowned quality standards, and the rotating A and C axes have torque motors for maximised usage with minimal service. The machine is available with a swivelling, multi-function touch panel having a 21.5 inch monitor.

[] To register your interest in the open house, contact Phil Morris,

Sales Director & General Manager, on 01926 485047/07714 826832.

Email: philip.morris@walter-machines.de

Website: www.walter-machines.com

Leave a Reply