Founded in 2000 by a father and son team, Bloom in Box was initially set up as a injection moulding business applying its combined 50 years of experience a handful of manual machine tools. Move forward 22 years and David Reardon has taken the reigns from his father, been joined by his children and the company now manufactures a complete range of its own product lines utilising its expertise in injection moulding, toolmaking and design.

In its infancy, the Burscough business was working like every toolmaking business – making products for customers in a B2B environment. Now, the company produces scoops and measures for the food & health industry, security fencing and wall spikes, laundry pegs, face visors and of course the floral range of bottle bouquets and the Bloomie living vases from where the company gets its name – it is also developing new medical and PPE product lines. All product lines are produced from recycled materials and are manufactured in-house at the Lancashire facility with support from Tamworth cutting tool manufacturer Industrial Tooling Corporation (ITC).

The small family-run business produces more than half a million scoops and measures a month, and receives more than 300 orders a day for its security spikes and laundry products and that’s before considering the extremely popular floral side of the business and other projects like run-flat systems for cars. One challenge the company had was with its cutting tool supply, recalling this, Owner and Co-Founder of Bloom in Box, Mr David Reardon says: “We were a small business with a Hurco VM10i machining centre and we used a couple of different and well-known tooling suppliers, none of which supported us fully as a small business. It was around 5-6 years ago we upgraded the machine to a larger Hurco VM20i 3-axis and we still had several sales reps that would suggest tools that would never fully resolve our issues – until we met Gary Murrey from ITC.”

It was the attention to detail and the time spent supporting and trialling the tools at Bloom in Box that really impressed David, as he continues: “Gary visited us and he helped us with tool set-ups, trials and advice – he put the effort into customer support. The attention to detail and picking the right tools for our applications yielded huge benefits for our business, it wasn’t just the ITC service that was far superior to other companies, it appeared the products were on a different level too.”

Predominantly machining P20 tool steel, Bloom in Box initially trialled the Widia M1200 face milling platform for rough machining. With impressive tool life and metal removal rates on rough machining applications, the tool proved a major success and the company adopted both the 32 and 40mm diameter variants with 7mm inserts. This paved the way for the next tool to be implemented at the environmentally conscious business that has a 40kW solar panel facility on the roof to run the majority of equipment in its machine shop.

Progressing from the Widia M1200 face mills, the family business was recommended the Widia VXF high-feed milling line. Recalling this intervention, David continues: “We were spending a considerable amount on solid carbide tools and in the injection mould industry, everything is tapered. This meant that we were unable to engage the full tool flutes and we noticed a lot of wear, but we also noticed a lot of waste, as we weren’t using the whole of the tool. To negate this issue, Gary suggested we try the Widia high-feed indexable series instead of solid carbide tools. We applied the VXF 07 16mm diameter and VXF 09 35mm diameter range and noticed a marked difference in performance and surface finishes with much higher feed rates and shorter cycle times, but more importantly, there was a huge reduction in our tooling consumption and costs.”

Now, almost all of the cutting tools at Bloom in Box are supplied by ITC as well as the robust machine vices from Kemmler. As David continues: “We have standardised our tool inventory in the machines now. This is mainly tools from ITC. The machines are set up for ITC tools with ITC’s Kemmler vices and our Autodesk PowerMill CAM software has all the parameters of the ITC tools loaded into the tool library, this makes set-ups and programming very simplistic.”

The company now applies a complete raft of ITC tools throughout the business with ITC’s solid carbide 2162 ball-nosed end mill range proving perfect for profiling intricate parts. The company also uses ITC’s 4052 taper ball nose tools, 6051 and 6071 end mills series, and the 2002 and the 2012 series of ball nose tools for aluminium alongside a multitude of Widia tools that include the GP end mills.

More recently the company has also invested in the BIG KAISER HMC hydraulic power chucks. Referring to this, ITC’s Gary Murrey says: “Bloom in Box is a company that machines injection mould tools that demand exceptional surface finishes. To improve the rigidity and stability of the tools, I recommended the BIG KAISER HMC power chuck and the BIG KAISER Mega 6S collet chucks to achieve the desired surface finishes and also improve tool life. Initially, David was sceptical, but after a short trial, he was hooked on the benefits of the HMC chucks.”

Adding to this, David says: “Our secondary hand finishing reduced significantly after we adopted the BIG KAISER HMC chucks and this saved us a lot of time and labour resources. We use a lot of tools with a long-overhang for reaching into cavities and difficult-to-reach surfaces, these applications are naturally less robust and stable. The BIG KAISER HMC chucks vastly improved the tool stability and run-out to deliver impeccable surface finishes.”

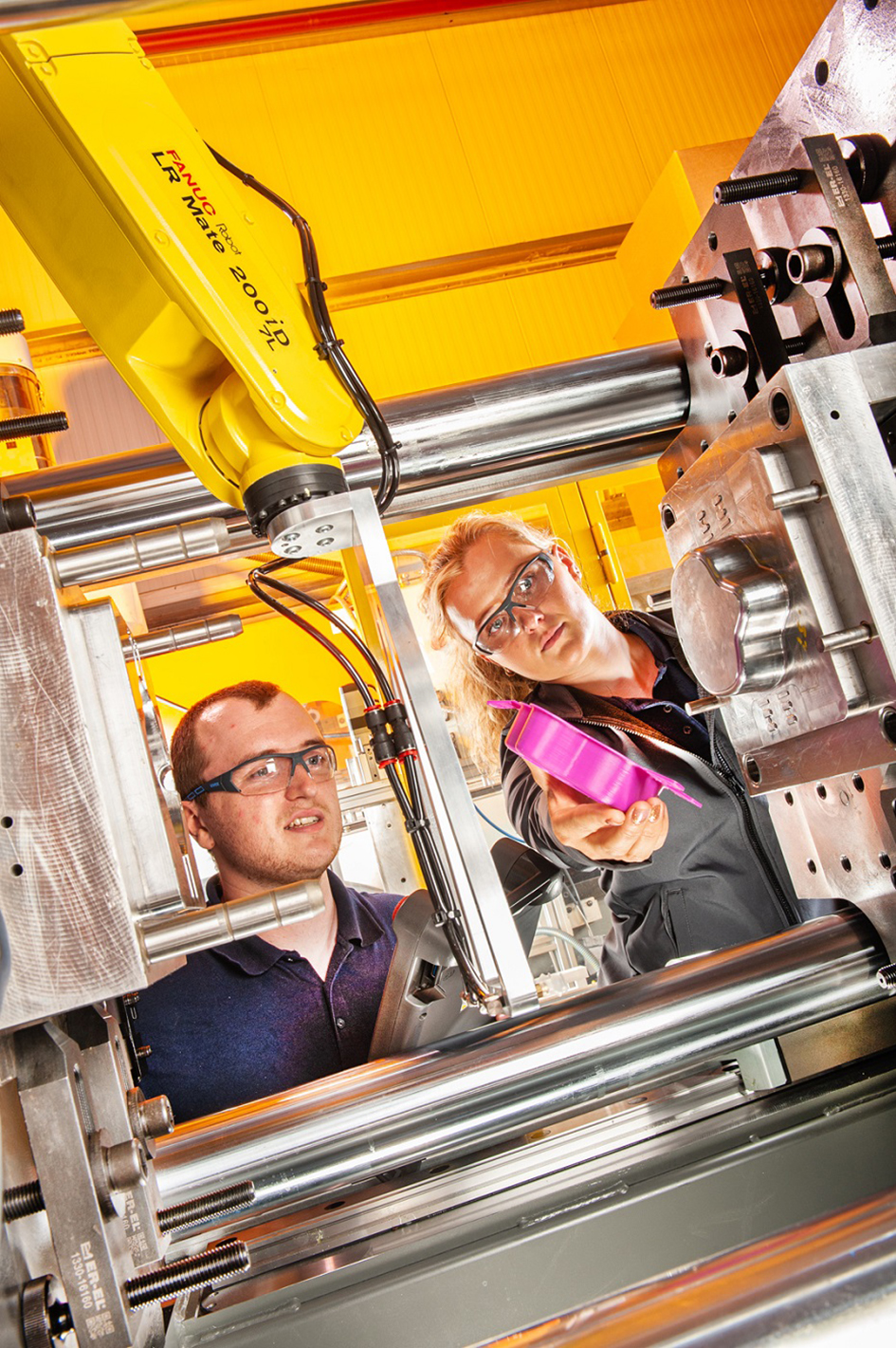

With four Victor injection moulding machines, a FANUC injection moulding machine and three FANUC robots, the company runs its high-tech facility 24/7. Regardless of its around-the-clock running, Bloom-in-Box is aiming to become carbon neutral over the next 12-18 months. It works with all-electric machines to reduce power consumption and emissions. Investing in state-of-the-art production equipment and solar energy equipment the company is currently calculating its carbon emissions at less than 10 tonnes of CO2 per year – the ultimate goal is net zero.

Furthermore, the company has developed innovative techniques to work with food-grade approved polypropylene, which is 100% recyclable. It is also exploring opportunities to work with compostable plastic. Concluding on this, David says: “We take our environmental responsibilities very seriously and we use recyclable materials in all our product lines as well as having a major drive to be carbon neutral. With regards to the machine shop, we run it from our solar power and have innovative products from ITC that help to reduce our machining times, power consumption and costs to improve our productivity and throughput – it’s a huge help to our business.”