With the MP6 geometry, Walter is rounding off its range for medium machining of steel (secondary application: ISO M, K, S). The MP6 combines features for medium machining, such as a positive rake angle, with those of roughing inserts, for example, a tough cutting edge. This makes it the perfect link between the existing MP4 geometry for medium machining (with excellent chip breaking on soft steels) and the RP4 geometry for roughing operations (with a tough cutting edge for high feeds).

Walter offers the MP6 geometry in CCMT, DCMT, TCMT and VBMT basic ISO shapes. The short primary chamfer on the cutting edge, which is characteristic of roughing inserts, ensures a high degree of stability, even in challenging conditions, for example when machining forged parts with interrupted cuts. The 18° rake angle, tough cutting edge and special chip breaking geometry ensure excellent chip control during medium machining.

Walter specifies feeds from 0.1 to 0.4mm per rev and depths of cut from 0.4 to 4 millimetres as the range for the machining parameters. To prevent vibration, for example with thin-walled components, Walter has given the MP6 geometry an open chip breaker groove. This reduces the cutting pressure even when cutting at a higher depth of cut.

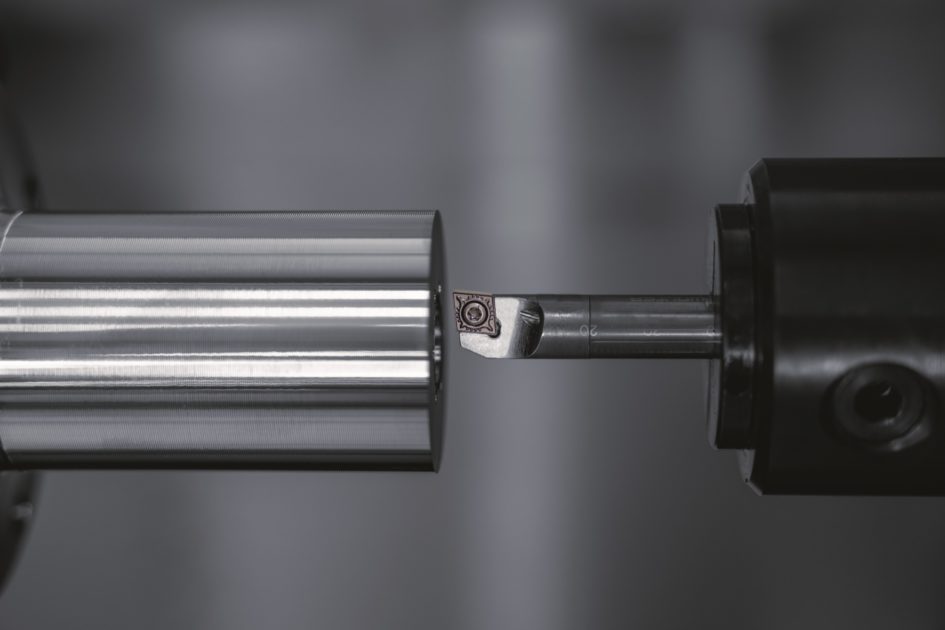

This also makes the MP6 ideal for unstable components and components with long overhangs, for example during internal turning. Its straight cutting edge makes it suitable for use as a chamfer insert, regardless of the application. The new Tiger·tec® Gold grades also have a positive impact on tool life. WPP10G, WPP20G and WPP30G are adapted to different operating conditions, leading to increased tool life and performance across a broad range of applications.