A new CNC steel processing machine from Ficep UK has been launched to bring greater choice to the UK wind tower and offshore manufacturing industries.

With the rapid growth of wind tower manufacturing, Ficep UK has brought to market its Energy CNC machine for steel plate drilling, milling, and scribing. The automated Energy machine has been developed to handle extremely large and heavy steel plates – up to 30m in length and 4m in width – ideal for use in the wind energy and offshore sectors.

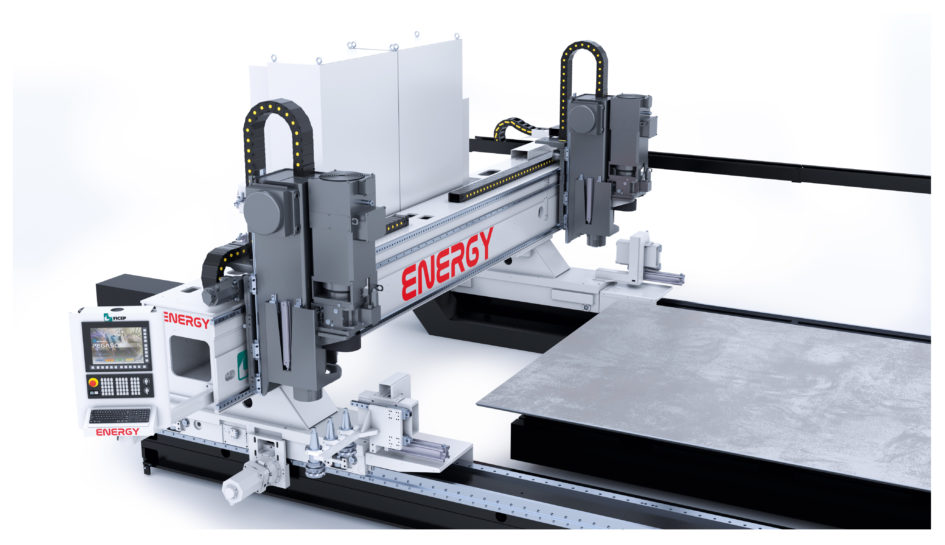

Suitable for applications including the manufacture of wind towers and pressure vessels, the Ficep Energy is a gantry-style fabrication system, with two separate working areas to optimise plate loading and unloading phases. Available in different bed lengths, it can accommodate longer plates and the table can be subdivided to create multiple processing zones. For added performance, the Energy starts with two 60 KW spindles that can accept milling tools up to 300mm in diameter for robust milling of plates up to 140mm thick.

The Energy incorporates a probing system to locate all the critical edges of the part prior to spindle operations, for ultimate precision. It also includes a tool changer system – mounted on the spindle board – which automates and expedites tool selection and replacement. The system can be integrated with other Ficep steel processing machines, including the Kronos – a heavy duty gantry-style system with optional dual drill spindles, which increase productivity in steel plate processing.

Says Ficep UK Managing Director Mark Jones: “The UK wind energy industry is growing rapidly, and so too are the size of the towers. Manufacturers need a reliable and efficient solution that is robust and can handle large expanses of material, which is exactly what our Energy system delivers. It offers a fast, precise, powerful, and simple system with an easy-to-use operator interface.

“Ficep UK has a reputation for quality machines and reliable support services, and our Energy system represents a credible new entry to the industry.”

www.ficep.co.uk