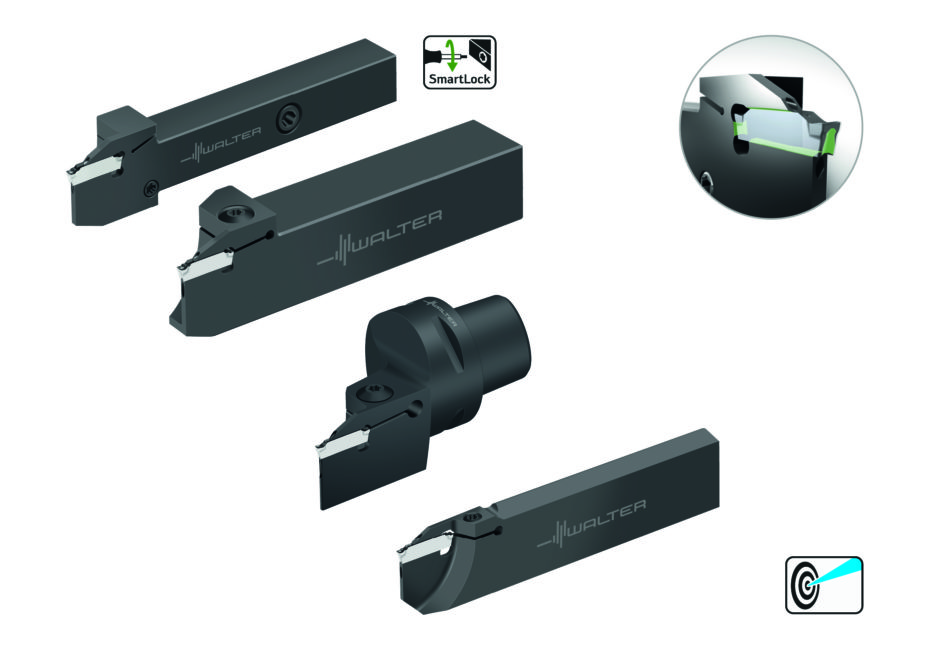

With the launch of the G4014 grooving tool holder with SmartLock, Walter has already succeeded in reducing insert indexing times for Swiss-type auto lathes and multi-spindle machines by up to 70%. To maximise the benefit of this breakthrough, the German-based manufacturer is now expanding its DX18 parting off and recessing range of inserts that work in harmony with the groundbreaking toolholders.

With the introduced G4014 series of toolholder, Walter is also using the double-edged DX18 indexable cutting inserts with Walter’s positive engagement design for the new additions in the form of the G4041 deep parting blades and the G4011 monoblock shank tools. This reliably prevents lateral movement of the inserts in the insert seat, therefore increasing the indexing accuracy, stability and process reliability. In addition, all ranges are available with and without precision through the tool cooling. Together with the raised chip shoulder that improves chip evacuation, higher feed machining is possible. Furthermore, it leads to extended tool life for both the cutting insert and the respective toolholder. The range for the G4041-P deep parting blades and Walter Capto™ G4011-P tools for universal applications now covers insert widths from 2 to 4mm and cutting depths up to 10mm and 17.5 mm, respectively.

The potential application ranges for the new Walter DX18 series are all machining operations from parting off and grooving with a flat groove base through to universal application for recessing and dynamic recessing. Regardless of the tool, users from all industry sectors can benefit from the high level of process reliability provided by the positive-locking DX18 cutting inserts and the high degree of productivity due to improved chip breaking.