Over the past decade, Managing Director Nick Street has driven the growth of Trust Precision (www.trustprecisionengineering.co.uk) in Eastwood, near Nottingham, which has become one of the leading providers in the Midlands of sliding-head turn-milled components. He said, “With a can-do attitude and living up to our slogan ‘where reputation is everything’, we have established ourselves as a benchmark for quality and reliability.”

Last year the company more than doubled its production area to 8,500 sq ft by moving into an adjacent factory unit. Part of the reason for expansion was to dedicate space for training and developing the skills of the subcontractor’s workforce, apprentices and operators from one of its largest aerospace customers that utilises similar machines.

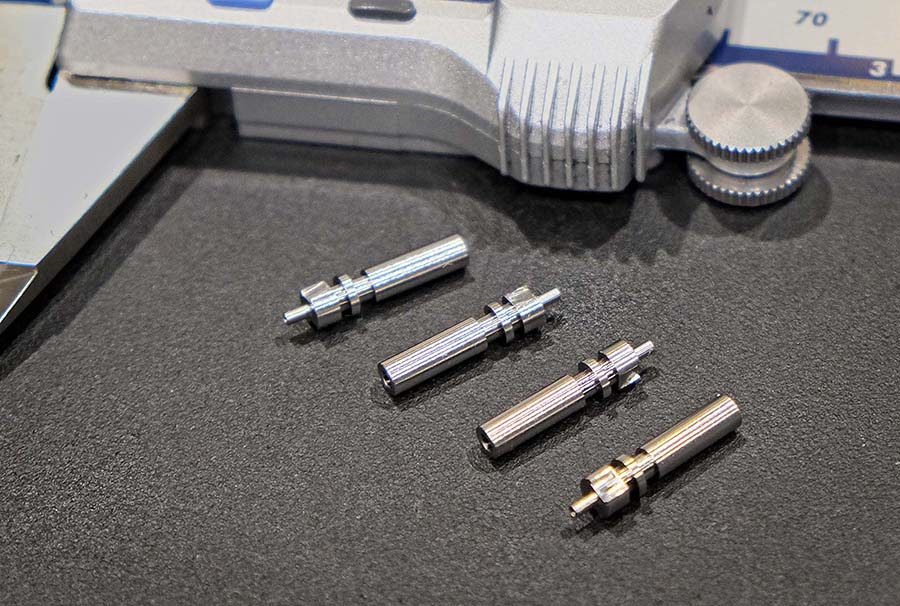

When he started his contract machining business, Nick took the view that for one-hit production of turn-milled parts, sliding-head lathes were able to hold size better than equivalent fixed-head twin-spindle lathes. It is possible to hold five microns total tolerance on most turned and interpolated features.

He already had considerable experience of Citizen Cincom (www.citizenmachinery.co.uk) as well as other sliding-head lathes at various subcontract firms in the area, so in 2011 he ordered the first Cincom M32-VIII, which was delivered fitted with a pneumatic guide bush that improves the machine’s ability to accept bar stock of variable quality and extends the bar capacity from 32 to 35 mm diameter.

Mr Street said, “With B-axis movement of one of the tool carriers and a total of nine cutters facing the sub spindle, the machine was at the time more advanced than most other lathes on the market, either sliding-head or fixed-head, so it was a straightforward choice to purchase the Cincom.”

It proved ideal and there are now six similarly equipped models operating around the clock at the Eastwood facility, lights-out overnight. All are fitted with 130 bar high-pressure coolant and a 3.6-metre bar magazine. The latest M32 addition, plus a 20 mm bar capacity Citizen L20-XII with a programmable B-axis and the manufacturer’s low frequency vibration (LFV) chip breaking software, were delivered in January 2020 directly to Trust Precision’s factory extension. Alongside them, the subcontractor operates the latest M32 variant that Citizen Machinery UK asked him to beta test.

Until the pandemic took hold in early 2020, up to 60 percent of turnover was derived from aerospace contracts, but the proportion is more like one-third of that now. The current shortfall in commercial aerospace work, due to Covid-19, has been largely offset by winning new business, primarily from the medical industry. The fall-off in work from the aerospace sector has presented the opportunity to focus more on training, which had been identified as the crucial element for the future development of the business. Mr Street commented that Covid-19 has been a benefit in this respect, giving the company the opportunity to focus more on this important element for the development of the business.

Fortuitously, the presence on the shop floor of the L20-XIILFV meant that its superior chip breaking ability could be harnessed for more efficient turning of medical parts from stainless steel bar. The material normally forms stringy swarf that wraps itself around the component and tooling, risking damaging both, but programmable LFV avoids the problem by breaking the swarf into a short, manageable length. The chip-forming functionality in the operating system of the Mitsubishi control is switched on automatically by G-code command for those parts of cycles where it is expedient to use it, and then switched off again automatically, resulting in significant improvements in productivity and yield.

In the case of an early medical job whose dimensional tolerances needed to be within ± 25 µm, LFV was switched on for about 25 percent of the cycle. After 1,000 components had been produced, there was no swarf damage to components or tool breakage, even though a 0.8 mm diameter hole was being drilled and reamed in the reverse end of the part.

Mr Street continued, “LFV is a must if you are buying a Citizen lathe that offers the option. It is a major technological advance, the more so because it can be activated by the part program. So the slightly lower metal removal rate during LFV can be restricted to those elements of the cutting cycle that benefit most from the chip control.

“Although the volume of our aerospace work diminished at the start of last year, just after we acquired the L20, the machine is proving useful for fulfilling medical contracts. The benefits will be felt even more in the future as the aviation sector recovers, as the stainless steels, titanium alloys and plastics we turn-mill for those customers all benefit from the chip breaking technology.”

Another feature of the machine that Mr Street appreciates is its ability to operate in guide bush-less, fixed-head mode for producing shorter parts economically. It also allows the machine to accommodate free-issue bar of indifferent quality. There is the added advantage of reduced remnant length and hence material savings. Only about 5 percent of throughput is currently machined without the guide bush in place, the remainder being shaft-type work, but for those contracts where it is possible the benefits are considerable.

With tongue in cheek, Mr Street concluded that LFV has one downside for experienced sliding-head lathe programmer-operators. It takes the black art out of chipping troublesome malleable materials so comprehensively that the playing field is levelled in favour of less skilled machinists.