The range of applications demanding skills in liquid silicone rubber (LSR) moulding is on the rise, with the medical, food and automotive segments driving significant growth according to a new study issued by Reports & Data[1]. Projected to be worth USD 3.83 billion globally by 2026, a rise of 7.3% CAGR, Nigel Flowers, Managing Director of Sumitomo (SHI) Demag UK explores the rationale for this renewed focus on LSR and how moulders can adapt their manufacturing capabilities to tap into this lucrative market.

Q1: What makes LSR so different to other moulding materials?

A: LSR is a fairly unique material in that it remains flexible and elastic down to -50°C, yet also retains its properties up to 200°C. This is why LSR is starting to be used more extensively in encapsulated electronic components, cables etc. where insulation is required for user safety. Additionally, LSR stands up well to UV and chemical exposure.

Because of all these features, LSR is a good material for automotive electronic components, such as headlight components, sealings and engine components. It also enables manufacturers to achieve geometries and technical features not previously possible, such as the moulding of complex optical surfaces onto a light guide for a matrix headlight, as demonstrated recently by Sumitomo (SHI) Demag at K-2019. We are starting to see high transparency grades being used in environments with powerful LED lighting, such as street and stadium lighting, as well as vehicle headlights, particularly in premium cars.

Q2: How can LSR be used in medical applications?

A: For many years LSR has been used in the baby care market, for pacifiers and bottle teats. Now, LSR is being used to create implantable devices, wearables to track blood pressure or heart rates, as well as smaller medical devices with more intricate designs and micro parts.

One of the key characteristics of LSR is its biocompatibility and the fact it is bacteria resistant, hydrophobic and odourless and can withstand repeatable sterilisation at high heat. All of which lend the material well to healthcare applications.

Q3: Can you overmould with LSR?

A: Yes, overmoulding works extremely well for a number of devices that require special aesthetics, for example a comfortable soft touch grip on tool handles or disposable razors. The ability to add adhesion to the material assists with this, and helps to reduce the number of production steps for a moulder.

Critically, LSR can be moulded onto both bondable and non-bondable materials, including metal, glass and ceramics. This assists with manufacturing efficiency, helping to reduce the number of individual components and consequently reduce assembly costs.

Sumitomo (SHI) Demag demonstrated the process of moulding a matrix light at K-2019

Q4: How does the processing of LSR vary to other materials?

A: The low viscosity of the LSR material requires high precision processing. Compared to polymer granules, LSR is almost honey-like in consistency. In that respect it behaves in the opposite way to conventional polymers during the moulding cycle. To keep LSR in its semi-liquid state before it arrives in the mould, the injection barrel is water cooled. Once it arrives in the mould, the LSR is heated and cured.

Q5: Is specialist equipment required?

A: Yes, in order to mix and process the material, you do need specialist equipment that can deliver the stability required to handle an optical grade silicone material. Although there are examples where traditional moulding machines have been adapted with an LSR injection unit, moulders may find that part quality or efficiency is compromised.

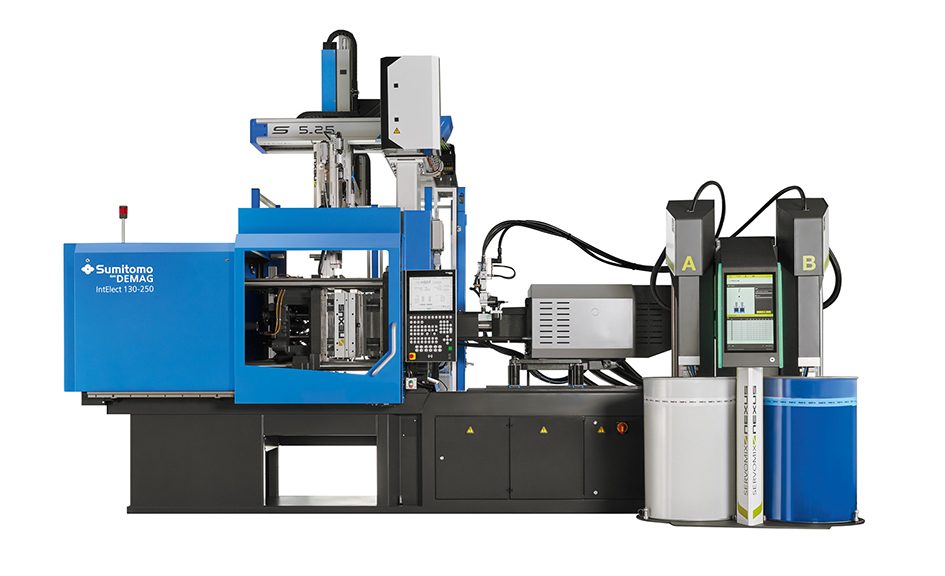

For this reason, Sumitomo (SHI Demag recently launched a ready-to-use precision IntElect LSR injection moulding package. Unveiled at K-2019, the all-electric IntElect 130 is equipped with a special screw, a non-return valve, vacuum pump and toggle technology. The cell was developed in collaboration with a number of partners that are dedicated to the LSR marketplace, including Nexus.

For the exhibit, Nexus designed the four-cavity LSR matrix light mould. The company also supplied the mixing and dosing unit, which stabilises the dosing and ensures a precise mixing ratio, irrespective of dosing volumes. The unit also performs automatic venting to detect and purge air from the material before it is fed into the machine and mould. Nexus has also designed a fully-automated downstream demoulding solution.

To optimise the quality of LSR components, Nexus offers a special cold-runner control technology. Enabling direct injection into each individual cavity via a needle valve gate, this ensures the filling of each mould cavity is balanced.

Q6: How is the moulding machine different to a standard IntElect?

A: Special screws, measuring between 14mm and 45mm in diameter, with a sealing system at the shaft are adapted to the material and machine size. Currently, the LSR package is available on IntElect machines ranging from 50 to 180 tonnes.

Other special features include a spring-loaded non-return valve to avoid uncontrolled backflow of material, a shut off system specifically designed for LSR, plus a pressure controlled vacuum sequence to extract air and to prevent flash occurring during the filling of the mould.

Additionally, Sumitomo (SHI) Demag’s Centre Press Platen ensures high rigidity and uniform distribution of the clamp force to ensure more balanced pressure distribution. While the robust linear guidance system controls the mould opening and closing sequence with a built-in staged clamp force, further reduces the risk of flash.

Q7: Do I need a cleanroom?

A: Typically, a standard all-electric moulding machine like the IntElect is an enclosed cell and therefore holds little risk with regard to cleanliness. However, parts being produced for the medical and life sciences sector are governed by stricter manufacturing hygiene guidelines. These instances may require investment in a certified cleanroom, limiting exposure to airborne particulates, contaminants and pollutants.

Sumitomo (SHI) Demag’s precision IntElect LSR injection moulding package is now available to customers globally.

Q8: Are any other applications suited to LSR?

A: Pet chew toys and other canine products, such as collapsible water bowls and slow feeders are just a few of the products being marketed now that use LSR. Primarily, the material is chosen for its durability. It’s reliable and stands up well to chewy teeth, making it safe for pets. It’s also visually appealing, as texture and nodules can be easily incorporated into designs.

Food grade silicone rubber is also used a lot in baking and home ware. Its not-stick nature lends the material well to kitchen utensils, as well as gaskets and seals.

[1] https://www.globenewswire.com/news-release/2019/07/17/1884105/0/en/Liquid-Silicone-Rubber-Market-To-Reach-USD-3-83-Billion-By-2026-Reports-And-Data.html