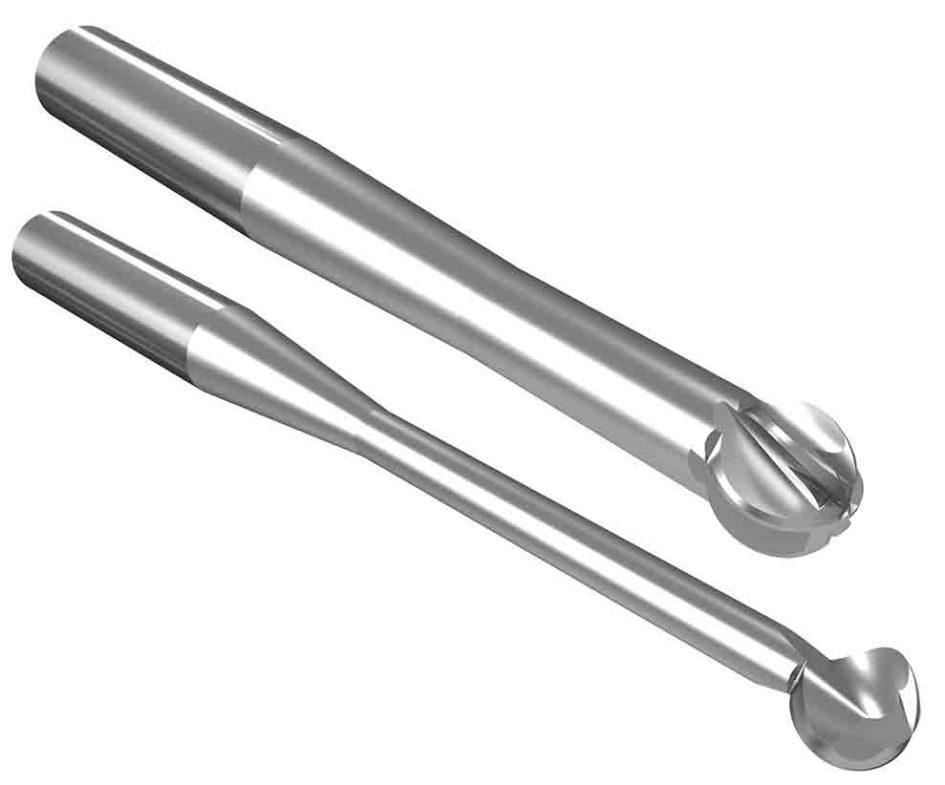

As technology leaders in the design and production of innovative cutting tool solutions, Quickgrind has now expanded its ‘Infinite Possibilities’ portfolio with the arrival of the new Orbis Lollipop cutter range.

Unlike most cutting tool manufacturers, the business model at Tewkesbury based Quickgrind is focused around the supply of products tailored to the demands of the end user, hence the ‘Infinite Possibilities’ branding. An example of this is the new Orbis series of Lollipop End Mill Cutters. As part of the ‘Infinite Possibilities’ range, the Orbis Lollipop tools can be designed to the specific dimension demands of the end-user, suiting the specific applications and material types regardless of industry sector.

The ‘Infinite Possibilities’ philosophy at Quickgrind means that the non-standard sizes and geometries are available to manufacturers with very short delivery times and at ‘near standard’ prices. Designed for 5-axis machining of intricate components with unique features, the solid carbide Orbis range enables access to difficult to reach features and surfaces. Furthermore, the Orbis series enables manufacturers to use a single tool to follow the most challenging of tool paths and component forms.

What this means for the end user is that the Quickgrind ‘Infinite Possibilities’ philosophy extends beyond what is possible with tool production into what is also possible on the machine tool. The Orbis has been designed to answer many of those challenging programming concerns where standard tooling is restricted from reaching and machining the most demanding of surfaces.

The Orbis range is available in 2, 3, 4, 6 or 8 flutes with a complete variety of lollipop and shank diameters, overall lengths and a vast range of reduced neck diameters. This unparalleled diversity gives the end user complete access to the workpiece regardless of complexity. Not only does the Orbis create unsurpassed workpiece access, the spherical ball profile and unconventional geometry enable the new range to excel in terms of tool life, machining speeds and feeds and surface finish quality.

Perfect for the fine finishing of irregular or uneven surfaces as well as the daunting prospect of tube machining, the Orbis even achieves ultra-fine surface finishes when targeting difficult-to-reach component features. This is credit to the uncompromising carbide composition of the end mills and the UK designed tool geometries that minimise vibration, even when reaching the most difficult to access surfaces. Also contributing to the reduction in vibration, cutting forces and the tool life and productivity improvements are the three unique geometry styles for alternate material types. The Orbis ‘A’ Series has been designed for the machining of aluminium whereas the ‘S’ Series is the perfect choice for cutting titanium, nimonics and other high-temperature alloys. In contrast, steel, hardened steel and other mould & die grade steel materials will achieve the best machining results when being machined by the ‘D’ series of Orbis Lollipop End Mill Cutters.