At this year’s formnext exhibition in Frankfurt, DMG MORI will be demonstrating its holistic expertise in additive manufacturing. The show will mark the world premiere of the LASERTEC 125 3D hybrid laser deposition welding system.

- World premiere LASERTEC 125 3D hybrid: Laser deposition welding combined with 5-axis milling for large parts

- AM Assistant: Greater process reliability for 3D hybrid machines

- LASERTEC SLM: Maximum precision in powder bed production

- DMU 50 3rdGeneration: Additive manufacturing plus conventional CNC machining

- DMQP: Cost-effective powder circuit with seal of quality and open powder selection

- my DMG MORI: Unique customer portal for more transparency, quality and speed in all service processes

- DMG MORI Economic Stimulus Program: Strong partner for every economic situation

As the leading global exhibition for additive manufacturing, formnext in Frankfurt is the ideal platform for DMG MORI to present a cross section of its extensive portfolio. In addition to the new LASERTEC 125 3D hybrid laser deposition welding system, the machine tool manufacturer will demonstrate the LASERTEC 30 SLM 2nd Generation and the LASERTEC 12 SLM to present its powder bed processes. A DMU 50 3rd Generation also be on display will supplement the additive process chain to include CNC machining. DMG MORI will also be providing insights into its customer portal my DMG MORI and the DMG MORI Economic Stimulus program.

World premiere: LASERTEC 125 3D hybrid

Laser deposition welding of large parts

With the LASERTEC 125 3D hybrid, DMG MORI has expanded its laser deposition welding portfolio to include a model for the maintenance, repair and production of significantly larger parts. Based on the sturdy monoBLOCK platform, it is designed for parts measuring up to ø 1,250 x 745 mm and a workpiece weight of up to 2,000 kg. The rigid machine construction and high dynamics of the LASERTEC 125 3D hybrid enable accurate, reliable and at the same time cost-effective complete machining of metallic 3D parts. Customers can expect high build rates and repeatability normally associated with CNC metalcutting machines. The new AM Assistant is part of the innovative software and hardware of the LASERTEC 125 3D hybrid. The hardware includes an integrated thermal imaging camera for continuously monitoring the entire working area. The AM Assistant also includes AM Evaluator software for intelligent downstream evaluation of 3D process data.

The highlight of this year’s formnext is the world premiere of the

LASERTEC 125 3D hybrid for workpiece weights of up to 2.000 kg.

LASERTEC SLM:

Maximum precision in powder bed production

The DMG MORI portfolio in powder bed technology includes the LASERTEC 30 SLM 2nd Generation with its large build chamber of 300 x 300 x 300 mm and the LASERTEC 12 SLM, which sets new standards in precision thanks to its focal spot diameter of just 35 µm. Measuring 125 x 125 x 200 mm it has the biggest build chamber in its class. A feature that all LASERTEC SLM machines have in common is powder change using the rePLUG powder module. On one hand, the closed powder circuit ensures a high level of work safety and, on the other, the powder can be easily changed within two hours – the fastest system on the market.

Powder bed machines in the LASERTEC SLM series are designed for productive manufacturing of complex workpieces.

Two technological processes with ADDITIVE MANUFACTURING and machining on a single platform

The LASERTEC 3D hybrid series is designed for the additive manufacture of complex prototypes and small series parts as well as for the repair and coating of components. It enables both additive manufacturing and CNC milling on one machine for the production of 3D components in finished part quality. The portfolio still includes the LASERTEC 65 3D, which is geared solely towards laser deposition welding as a complement to existing machining centres on a shop floor. The LASERTEC SLM series expands the portfolio to include the powder bed method using selective laser melting (SLM). Thanks to the combination of additive manufacturing technologies with conventional CNC machines, such as the DMU 50 3rd Generation that will be on show at formnext, DMG MORI has realised individual needs-based process chains.

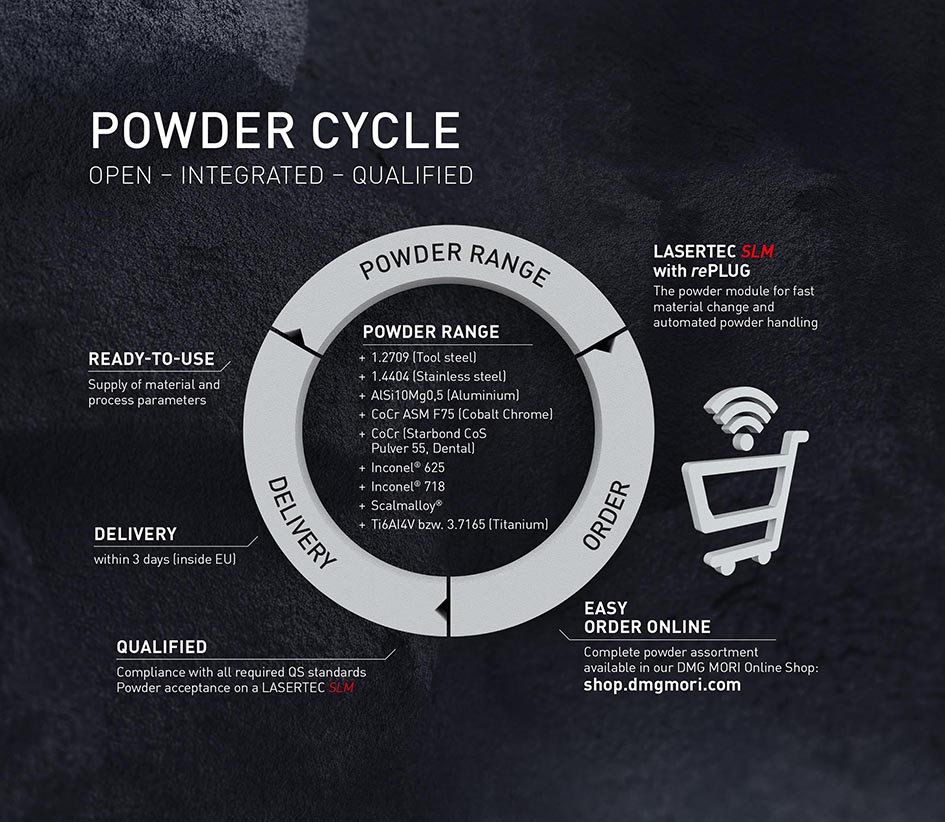

DMQP: Cost-effective powder circuit with seal of quality

DMG MORI has underlined its holistic process thinking by extending the range of DMG MORI Qualified Products to peripheral and accessory components for additive manufacturing. The main focus is on open powder selection and having a qualified, integrated powder circuit. Powder return and recycling with selected DMQP partners provides an economical way of processing expensive powder materials. A competent DMQP partner has been acquired in this area in the form of Hanau-based Heraeus, which ensures that a comprehensive powder portfolio that fulfils the strict quality standards is available to customers. DMG MORI has also conclusively validated these standards on a LASERTEC SLM powder bed machine. The wide range of materials in the DMG MORI web shop ranges from tool steel and stainless steel to aluminium and cobalt chromium to Inconel and titanium, meaning that almost any requirement in the target industries can be covered – worldwide and within just a few working days. All powder is said to be marked with a DMQP seal of quality and ready to use, since it is provided with the relevant parameters.

The DMQP program concentrates on open powder selection as well as on a qualified and holistic powder cycle.

my DMG MORI:

Unique customer portal for more transparency, quality and speed in all service processes

Maximum customer benefit is also the focus of the new digital customer portal my DMG MORI. Here, DMG MORI brings together its future-oriented initiatives “Integrated Digitization”, “First Quality” and “Customer First”. The result is an online portal for interactive cooperation between DMG MORI and its customers. Among other things, service requests can in future be started virtually at the press of a button via my DMG MORI, the interactive request form preventing any misunderstandings. Specific service requests and the option of attaching photos or videos immediately reach the right DMG MORI service expert, while the “Tracking & Tracing” function ensures transparency for all service processes and procedures. Even orders for spare parts can be tracked to the minute.

my DMG MORI: Unique customer portal for more transparency, quality and speed in all service processes.

DMG MORI Economic Stimulus Program:

Strong partner for every economic situation

After years of growth, many DMG MORI customers now face uncertain economic times. The machine tool manufacturer is taking advantage of its global presence and unique and wide range of services and products to position itself as a reliable partner, especially in this situation. Based on a comprehensive five-point Economic Stimulus Program, DMG MORI is able to provide its customers with economical long-term support in the areas of further training as well as service and machine technology. All measures perfectly complement one another and are all from a single source. The programme, which is available in Europe, includes a machine buyback option to ease cash flow, risk-free financing models from DMG MORI Finance, training courses in which the DMG MORI Academy provides more know-how for users, and the DMG MORI Full-Service package for trouble-free production and machine overhaul by DMG MORI Used Machines as an alternative to a new purchase.