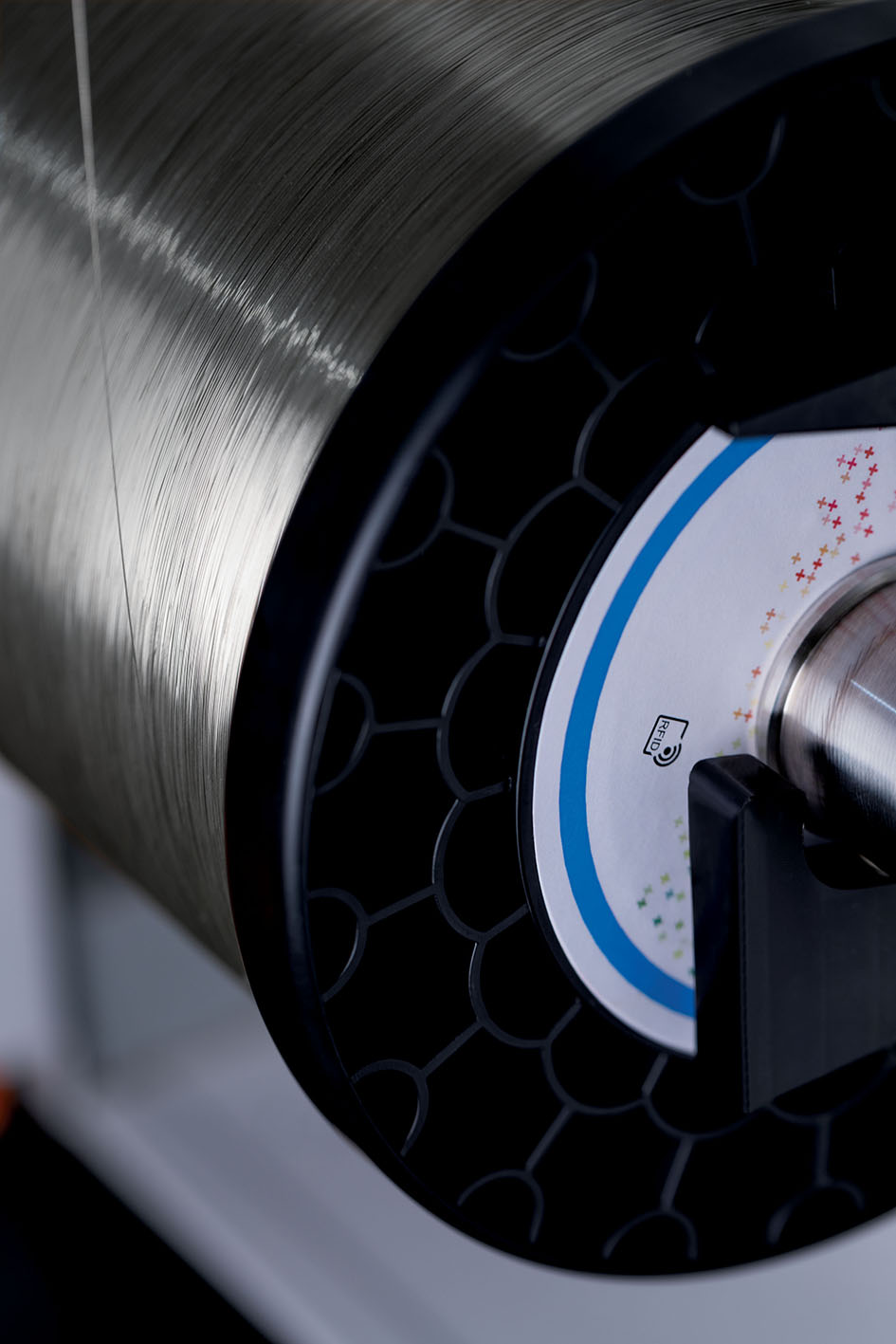

GF Machining Solutions has introduced SMART (EDM) wire technology equipped with radio frequency identification (RFID) chips that enable manufacturers to fully exploit the potential of their AgieCharmilles CUT P wire EDM machines and, simultaneously, achieve Industry 4.0 level process control.

GF Machining Solutions supplies high-quality EDM wire to its customers.

The company’s premium wires feature RFID chips which facilitate greater process continuity and traceability, as well as delivering improved process performance.

Process continuity

Thanks to SMART wire’s monitoring capabilities, the machine operator always knows how much wire is available for current jobs. The moment a spool of SMART wire is installed, the CUT P machine recognises and ‘logs’ the wire length. This means that, at a glance, the operator knows the status of wire spool status and whether there is enough wire on the spool to complete the cutting operation without facing any stoppages or interruptions.

Process traceability

At the same time, wire traceability is enhanced by the data, including date of manufacture, type, lot and expiration date, in the machine report. Advanced traceability is especially important in wire-cutting EDM applications in the risk-averse aerospace and medical sectors.

Process enhancement

SMART wire users can be confident that they are using the optimum wire for every job, because the SMART technology checks and assesses the wire selected and then optimises the performance of the machine accordingly.

GF Machining Solutions’ premium wires feature RFID chips which facilitate greater process continuity and traceability, as well as delivering improved process performance.

A SMART wire for all requirements

Always in tune with customers’ needs, GF Machining Solutions offers a wide range of SMART wires to help improve process continuity and traceability and optimise machine performance.

For example, if the machining priority is surface quality, GF Machining Solutions’ AC Cut AH 900/500/400 and AC Cut A 900/500 SMART wires are recommended.

To achieve improved productivity, AC Cut VS 900+, AC Cut VS 900/500 and AC Cut D 500 SMART wires are the option to choose.

If cutting speeds are the priority AC Cut VH SMART wire and AC Brass 900/500/400 are an effective solution.