Through the 1980s and into the early 1990’s, Ted Ford was working as a general manager for a single crystal diamond (SCD) tool company that was heavily involved in the super finishing sector. However, mergers and acquisitions gave Ted the opportunity to buy the diamond tool division from Norton Abrasives and in 1993, STF Precision was born.

STF Precision Headquarters

Unlike most cutting tool manufacturers that graduate from standard cutting tools and progress to high-end product lines; STF Precision applied its expertise in ultra precision super surface finishing SCD tools and transferred the knowledge to enter the diamond coated and PCD cutting tool sector – eventually progressing into the solid carbide cutting tool market. The journey from SCD into PCD started in 2001 when Ted sold the business to his son Jason Ford. Jason decided to extend the product portfolio and the Arden, N.C business bought a series of wire erosion machines and then a PCD erosion machine from Vollmer. This really changed the company’s fortunes.

Two of the latest acquisitions include the VPulse500 and the QM Eco from Vollmer

At the time of the acquisition, Ted had grown the company to a 5 employee team with a turnover in the region of USD$1m, but it was the sale of the business to Jason and his desire to push PCD tooling that opened the door for Vollmer. Starting off with diamond coated drills and countersink tools for the aerospace market, Jason realised that the Vollmer QXD200 disk erosion machine was the optimal choice for the business. Recalling the arrival of the first Vollmer machine over 15 years ago, Jason says: “We looked at all the available options but the Vollmer was by far the best machine. As a company we recognised the opportunities of erosion grinding machines from Vollmer for developing fluted PCD tooling, especially with the rise of composite materials in the aerospace industry. We wanted to loosen the stranglehold that some competitors had on this market segment and it was Vollmer that helped us to attack this area. In addition, we were a relatively small company at the time and Vollmer gave us favourable financial terms to get the first machine through the door.”

Bringing the first Vollmer QXD200 machine to the USA in 2006, STF Precision initially struggled to break the aerospace sector in the early 2000’s, but fortunately the flexibility of the QXD200 provided the opportunity to extend its offering for the automotive market. “Being a business known for its micron precision, we started to get into the automotive industry and the production of cutting tools for piston production. We started making groove tools, insert and form tools and much more. With an ability to produce tools to a precision level of less than +/-2microns with form angles below +/-15minutes, we found a niche manufacturing tools for machining high silicone content materials in the auto market. We got an opportunity with globally recognised Tier 1 auto companies like Linamar that makes parts locally. From there, we progressed to other prestigious companies like Honda Canada, ZF, Denso, Borg Warner, Toyota and many others.”

The Vollmer QWD and VPulse500 wire erosion machines running side by side

The Journey With Vollmer

Building the foundation for growth, the arrival of the first Vollmer machine was one of the cornerstones for growth at STF Precision, as Company President Jason Ford continues: “From 2001 to 2008, we had grown from US$750,000 turnover to over US$3m, with our investment in Vollmer technology and automation down the years, we now have a turnover of US$12m and more than 70 staff. Vollmer has supported us, not only with favourable financial terms but also on our journey to automated tool production. Now, we are running machines unmanned overnight and this was a necessity for reaching our growth targets. We started out in a 1500sq/ft bay making high-precision skiving and lapping tools and equipment, now we are in a 40,000sq/ft factory making high-end cutting tools for the automotive, aerospace, optical and general manufacturing markets.”

Two of the automated Vollmer QXD machines in operation

Progressing to Automated Production

Following the first QXD200 machine in 2006, another two QXD200 machines rapidly arrived between 2008 and 2010 for the production of milling cutters, reamers and drills with a QXD250 arriving in 2012. “The wire machines we purchased before the arrival of Vollmer’s required a 4th axis rotary head for processing round tools. The Vollmer QXD200’s and QXD250 were at least 30% faster; they were far more efficient and certainly more accurate. Furthermore, without the wire we are removing the potential for wire breakages and the associated downtime. We also installed the new QXD machines with 29 tool station loaders that gave us unmanned automated production around the clock and on weekends. We more than doubled our production capacity with just a skeleton second shift to load machines on evenings and weekends. We certainly wouldn’t have been as successful as we are if we didn’t have the QXD machines.”

With its exponential growth trajectory, STF Precision progressed into more complex geometry PCD form tools for the automotive market. In 2014, this resulted in the Arden business investing in its first Vollmer wire erosion machine. “Our customers were requesting more complex internal form tools and large diameter milling cutters and once again we turned to Vollmer. The solution was the QWD760 machine and as far as I’m concerned, this is the most accurate wire machine in the world for processing cutting tools.”

The first QWD760 machine proved so successful, a second machine arrived in 2016. As Mr Ford recalls: “The QWD760 is a great machine and we were so happy with it, we installed a QWD760H with a 12 station automated loader soon after the first machine was installed. With our complex geometry automotive tools taking upwards of 3 hours to process, the 12 station QWD760H can run for days without operator intervention.”

The added capacity provided by the automated Vollmer QXD and QWD machines has seen the STF Precision product portfolio expand beyond all recognition in recent years. Designing and developing solutions in close co-operation with its customers, the automotive customer base has evolved beyond bespoke piston production tools to specialised tools for engine blocks, cylinder heads, transmission casings and other powertrain, transmission, axle and suspension parts. The Vollmer installations have perfectly positioned STF Precision for growth in the automotive industry with more than 65% of the company’s turnover generated from the auto sector. However, the relentless precision, productivity, capability and flexibility of the Vollmer machines have also positioned STF Precision for growth in the aerospace market.

“The super surface finishing SCD cutting tools have remained a small percentage (5%) of our business due to their niche market applications. However, these SCD tools are gaining popularity in the automotive market and this puts us in a good position moving forward. However, the real growth market at present is the aerospace industry. In recent years, this has grown to become 25% of our turnover and we see great potential for growth here,” states Mr Ford.

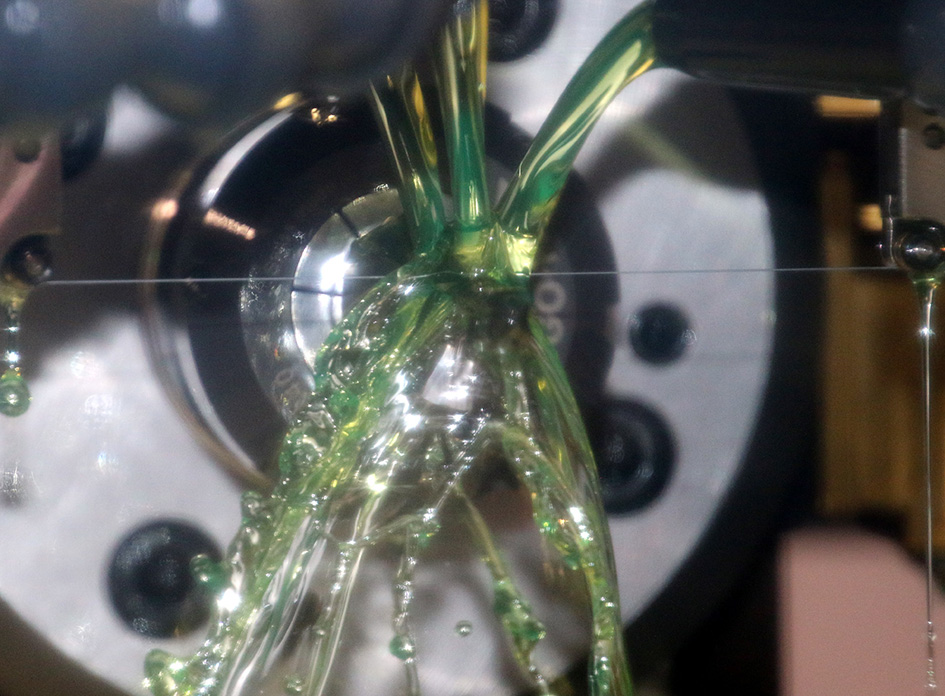

The QWD in operation at STF Precision

Nothing Comes As Standard

The proud manufacturer of high quality cutting tool solutions sets itself apart from other vendors by removing itself from the standard catalogue items that are manufactured in high volumes. The brochures on the STF Precision website emphasise the dedication to customer service and rapid turnaround through the consultation and design to production process. Demonstrating the diversity of the STF portfolio, some of the products available include PCD single and multi-groove tools, PCD and CBN indexable inserts, SCD inserts, form tools, custom diamond tools for NASA, knife tools; PCD and SCD rotary tools that include tipped drills, end mills, reamers, countersinks, ball nosed tools, multi-stepped drilling, reaming and countersinking tools, bolt hole drills, automotive wheel tools with multiple entry angles and CBN indexable inserts. Added to all this, the company manufactures a complete selection of solid carbide form tools, end mills, step drills and reamers with dimensions and geometries to suit the exact demands of the end user.

Not only can STF manufacture these tools on its range of Vollmer machines, it also has a range of turning and machining centers for the production of monoblock and indexable insert tool bodies. Furthermore, the company has witnessed significant progress with its solid carbide tooling department. Once again, STF Precision turned to Vollmer, installing the Vgrind 160 with HP160 pallet loader in 2017. As Mr Ford continues: “We bought the Vgrind 160 because it has the flexibility to pocket PCD tools and also manufacture complete solid carbide tools. Our initial thinking was to install the machine for pocketing PCD tools, but our growing deviation into carbide tools has seen the Vgrind become dedicated to producing carbide drills, end mills and reamers from 2.5mm to 25mm diameter. From a PCD perspective, the Vgrind is now just a ‘back-up’ machine to the QXD and QWD’s.”

The 5-axis Vgrind 160 incorporates two vertically aligned grinding spindles with the wheel set in the C-axis pivot point. This innovative kinematic configuration enhances rigidity and the subsequent surface finishes on the cutting tools whilst reducing processing times considerably. Solving multiple issues related to fixed and floating bearing machine configurations, the Vgrind 160 demonstrates enhanced thermal stability, power and precision characteristics. From an automation standpoint, STF Precision selected the Vgrind 160 with the HP160 pallet magazine loading system. Depending upon the tool shank diameter, the HP160 is capable of loading up to 272 tools for prolonged periods of unmanned processing.

“We are now producing and supplying our customers with over 300,000 PCD inserts each year. Added to this, we are producing hundreds of bespoke PCD cutting tools and brazed tools every month. This number of PCD tools doesn’t include the recurring servicing of PCD tools for existing customers. However, it’s the solid carbide market that is growing in volume. The carbide business is lower-cost higher volume and we are already manufacturing a few thousand end mills, reamers and drills every month.”

The 29 station auto loaded Vollmers enable 24 hour unmanned tool processing

The future…

With continued growth, STF Precision visited the Vollmer VDays event in 2018 and was immediately impressed by the latest VPulse 500 innovation. The next generation wire erosion technology was immediately purchased and is taking STF Precision to new levels of efficiency and precision, credit to the new erosion generator technology. Utilising the tried-and-tested Vollmer VPulse EDM erosion generator and incorporating it for the first time into wire erosion, the VPulse 500 demonstrates higher material removal rates or optimised surface quality; providing the optimum outcome for STF Precision’s production objectives. Furthermore, the VPulse500 has been purchased with the HR external workpiece storage and automation system. This enables the customer to process up to 16 tools with a maximum diameter and length of 300mm and 500mm respectively.

In conclusion, Jason Ford says: “Vollmer have been instrumental in our growth. The technology, capability, flexibility, service and support from Vollmer has been outstanding down the years and they have been at our side throughout our growth journey. They always seem to have a solution to our tool manufacturing needs, however diverse.”

“Recently, an industry contact asked if we could produce circular saw blades up to 430mm diameter for cutting 8 by 4ft glass fiber boards for the construction industry – and we couldn’t. The opportunity was sufficient enough to justify buying a machine and it was once again Vollmer that had a solution with its QM ECO Select. The 5-axis QM erosion machine is perfect for PCD and TCT tipped saw blades and despite this venture being in its infancy, we are already producing 5 to 10 new saw blades each month with up to 10 blades being serviced and re-sharpened every week on the machine.”