At this year’s Formnext event held in Frankfurt, 19-22 November, FELIXprinters will be showcasing its range of innovative, highly accurate, repeatable, and cost-effective industrial additive manufacturing (AM) machines on booth A66 in hall 12.1

FELIXprinters is today recognised as a prominent AM platform developer, and is finding significant elbow room in the sector as its reputation for affordable high quality AM solutions becomes more and more widely accepted across all relevant industry sectors.

Guillaume Feliksdal, Co-Founder at FELIXprinters says, “Formnext in our eyes is by far the most influential show for industrial users of AM for production applications. As such we are excited to attend this year, prominent on our booth being the larger build envelope machines, the Pro L and XL, specifically designed for exacting industrial production projects. We are also profiling our move into the bio printing arena at Formnext, which is based on years of R&D that has now yielded a commercially viable AM technology — the FELIX BIO 3D printer. And finally, we are looking forward to Formnext as a place where we can showcase our ability to tailor-make AM platforms for specific customer demands. As a company, we are unique in the way that we work with our customers, with the ability to custom build AM platforms that are application-specific to ensure optimum output and results for manufacturers that come from an array of industry sectors.”

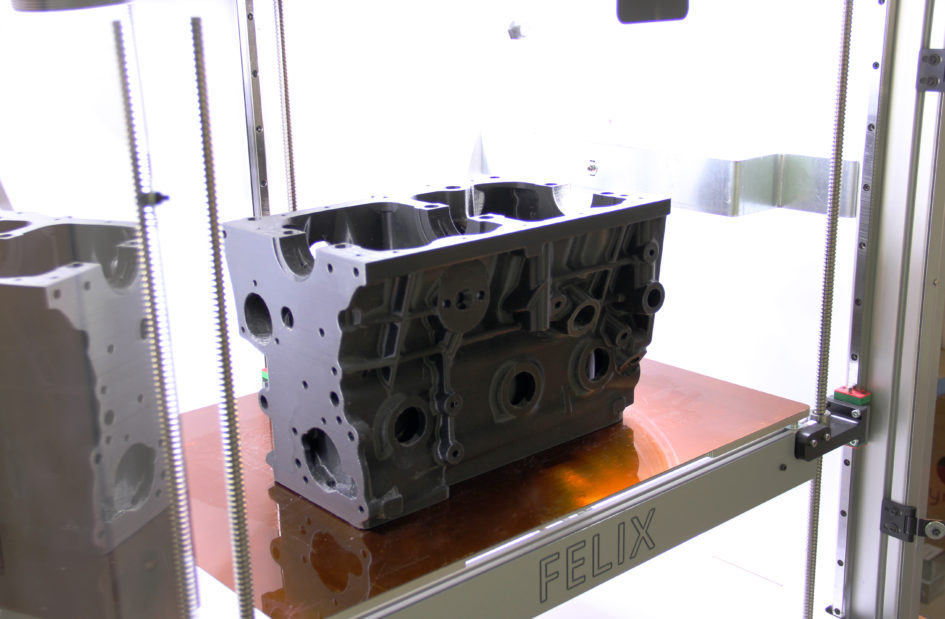

The FELIX Pro L and XL machines will dominate the FELIXprinters booth at Formnext, due to their scale. They have been developed with greatly increased build volumes over the existing family of Pro machines. The Pro L can build parts up to 300 x 400 x 400 mm or 11.8” x 15.75” x 15.75”, while the Pro XL has a build chamber of 600 x 400 x 600 mm or 23.62″ x 15.75″ x 23.62″. To ensure the quality and reliability upon which FELIXprinters has built its reputation, both of these larger systems incorporate highly engineered print chambers, which incorporate an enclosed warm zone and a cold zone. The warm zone supports consistent temperature control during the build, which is particularly important when printing materials with a high shrinkage factor, such as ABS, carbon fiber or Nylon. In contrast, the cool zone is where the electronics are housed, to prevent overheating and subsequent machine/build failure.

Wilgo Feliksdal, Co-Founder at FELIXprinters continued: “The new Pro L and XL systems come with our specific engineering expertise built in to them, as demanded by our customers. This includes a range of automated and intelligent features that remove many of the tedious and time-consuming hurdles often associated with additive manufacturing and speeding up the overall process. For example, the design of the dual nozzle. When the dual extruders are printing together they are at different print levels, avoiding any collisions and minimizing print failure. Then, if one nozzle is idle, it is automatically rotated out of the way so that there is no interference with the printed part. This avoids damage to the part being printed, and hugely reduces (if not negates) print failure, which is one of the most frustrating issues 3D printer users tell us they face.”

“We are extremely proud of the quality of all our AM machines, and were delighted when our technology was independently assessed recently, and received some amazing results. The test was conducted by Belgian-based company Trideus, which concluded that our Pro XL machine was the first large volume printer that delivers the same quality and detail as Ultimaker. Trideus reported that this was the first time that they had tested a machine of this size that achieved that. As you can imagine, this sort of feedback is extremely gratifying, and places us in a great position to attract serious commercial specifiers at Formnext.”

FELIXprinters is really keen to work with interested parties in a unique way at Formnext. Attendees are invited to bring details of specific applications to the booth that FELIX’s team of on-site experts can discuss to advise of the FELIX AM platform that will best fit specific requirements, or discuss customized soltions.

Guillaume Feliksdal continues, “By asking companies to challenge us with specific applications, we not only position ourselves as being able to accommodate a large and diverse range of production applications, but also promote the relationship that we insist on with our customers. When it comes to the use of AM as a manufacturing and production technology, we see ourselves as a strategic partner, here to guide, and ensure the best fit and most economical use of AM for specific customer needs. We do not just sell machines off the shelf and leave buyers to figure out the rest for themselves. We ensure a level of pre- and post-sales engagement that gives companies that work with us the confidence that they are getting the best return for their investment. In addition, our machines are all upgradeable, which means that platforms grow with the needs each company has over time, without the costly necessity to buy new machines.”

Come to see FELIXprinters at Formnext, and discover the numerous AM options that are available at the sweet spot between value and quality.