The most powerful flat-bed laser profiling centre ever to be installed in the UK for processing sheet metal has started operation at subcontractor ESP Laser Cutting (www.esplaser.com), which specialises in producing components from 3 metre x 1.5 metre sheet in a wide array of materials to a thickness of 30 mm. The investment follows the development of a 12 kW fibre laser source by Swiss manufacturer Bystronic (www.bystronic.com), whose Coventry subsidiary delivered a machine of that power, a ByStar Fiber 3015, in April 2019 to the contract machinist’s factory in Rotherham.

The increase in productivity has been remarkable. Delivering one-fifth more energy to the metal sheet than the previous most powerful fibre laser (10 kW), the new source was expected to be 20 per cent faster at cutting. What ESP’s joint owners Steve McMillan and Paul Short actually experience is a typical productivity increase of one-third. It is partly down to the higher power, but also due to the provision of a newly designed cutting head.

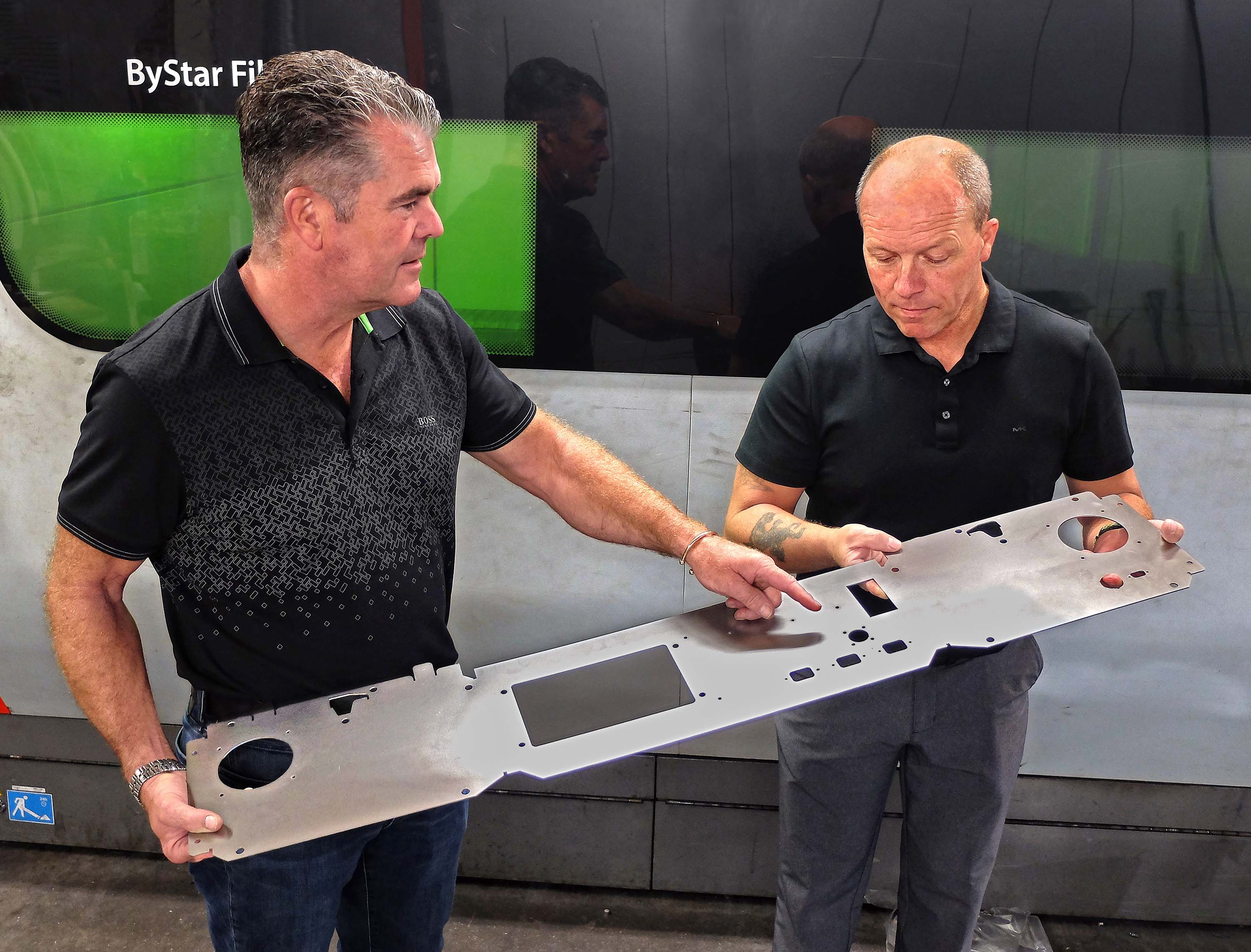

Paul Short (left) and Steve McMillan, joint owners of ESP Laser Cutting, inspecting a control panel part that has been laser cut from 1.5 mm mild steel sheet on their new 12 kW ByStar Fiber 3015, the first to be installed in the UK.

Contributing also to the higher than expected efficiency is a cutting plan algorithm running in Bystronic’s latest BySoft 7 nesting and control software that executes the most efficient route around the nest. It also minimises the risk of cut parts tilting, protruding from the material surface and interfering with the nozzle, avoiding the need to use micro joints and saving even more time when the sheet exits the machine by making shaking-out of the parts easier.

For processing one particular job, profiling of chain links from 10 mm mild steel sheet, an exceptional three-fold productivity improvement was gained on the 12 kW machine. When formerly profiling the parts on the ByStar Fiber 10 kW machine that is still in use at the Rotherham facility, 200 components per hour was the maximum output, as there was not sufficient laser power to employ nitrogen as the assist gas. Oxygen had to be used, requiring the cutting speed to be reduced so that acceptable edge quality could be achieved.

The 12 kW ByStar Fiber started operation at ESP in April 2019

By contrast, the 12 kW machine produces 600 parts per hour, as the higher power allows the use of nitrogen and hence full profiling speed. There is the added advantage that cut edges are better, especially on the underside of the sheet, than when formerly using ‘active’ oxygen, as ‘inert’ nitrogen does not react with the sheet material. ESP employs a profiling speed of 6,900 mm/min when producing the chain links, although the machine is capable of 150 m/min on thin gauges and accelerates at 2.5g to minimise non-cutting time.

Steve McMillan said, “We started ESP 25 years ago with a 1.2 kW CO2 laser cutter, buying a second, 1.5 kW model four years later. We were early adopters of the technology and have been using it constantly over the years, witnessing its progression.

“During that time we have repeatedly part-exchanged our two machines, buying a total of 10, of which the last eight were from Bystronic. The three most recent models have been fibre lasers, which have now almost completely replaced CO2 in our industry.

“We noticed a hike in productivity when the 6 kW fibre arrived in 2013 and another when the 10 kW version was installed three years later, which at the time was the first in the UK. However, the 12 kW laser cutter is the best machine ever.

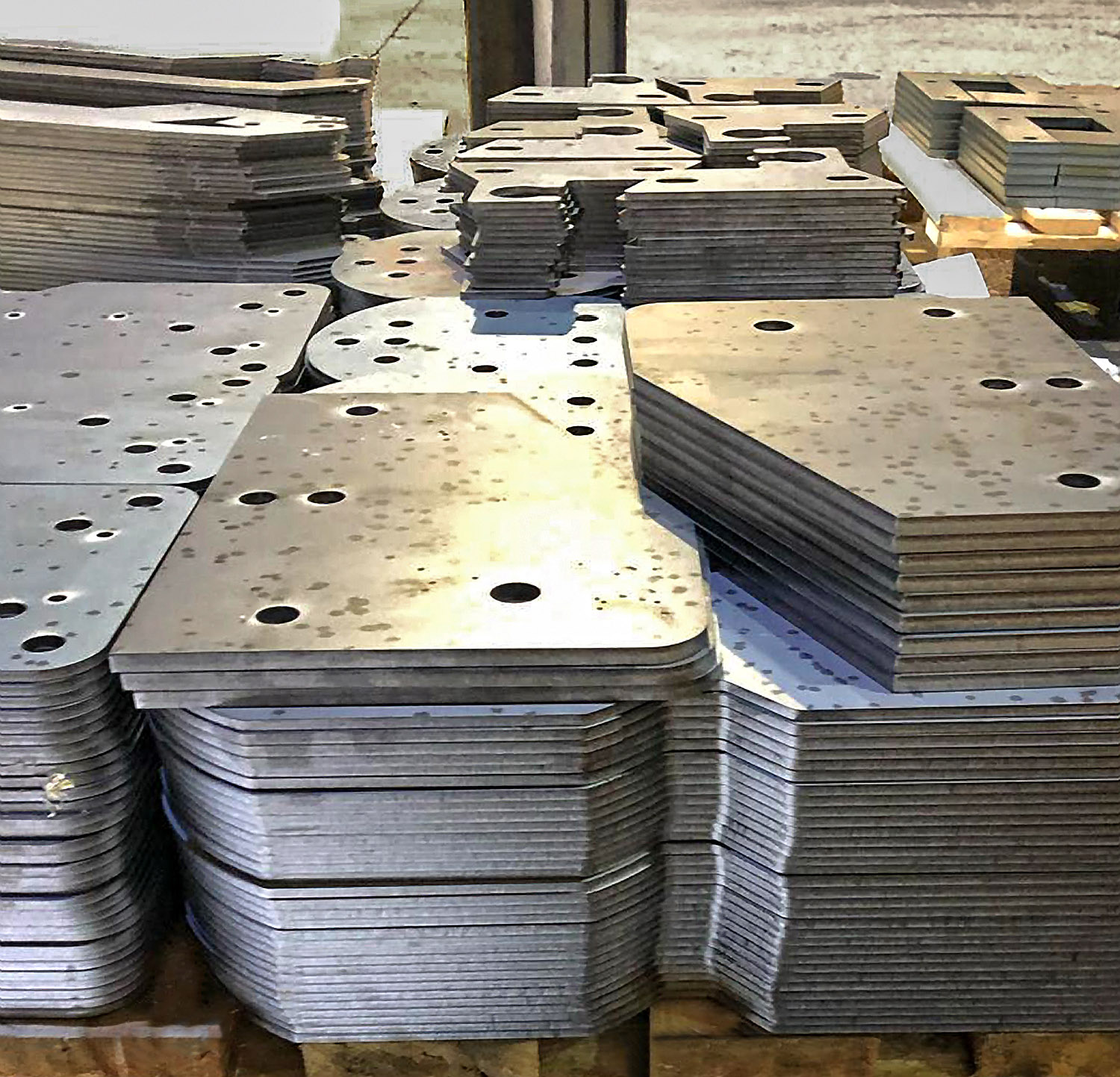

Parts cut on the 12 kW ByStar Fiber at ESP being removed from the sheet

“We simply plugged it in and it ran from day one. It is unbelievably quick, so you can make money even on jobs where you have to pare back prices to win work – and you can guarantee short delivery lead-times as well.”

Paul Short added, “Every increase in power delivers a cleaner cut edge, especially on mild steel which forms the majority of our throughput. The BeamShaper functionality in BySoft 7 optimises the shape of the laser beam when cutting heavier gauge materials on the 12 kW machine and produces a finish that is second to none on materials above 15 mm thick.

“Fibre technology reduces running costs considerably, as there are no expensive optics to replace and there is no need to spend a lot of time and thousands of pounds on maintaining a CO2 machine and its resonator.

“At the same time, power consumption is dramatically reduced. In 2013 when we were running a 6 kW CO2 machine alongside a fibre model of the same power, the former was drawing 100 kVA while the latter consumed 33 kVA.

Pallets of components laser cut by ESP ready for delivery. The subcontractor has 3,350 customers on its books spanning the catering, shopfitting, marine, electronics, aerospace, machine tool and defence sectors, 1,800 being active at any given time.

“Three years later when we went all fibre, we were saving £4,000 per quarter in electricity costs. It started to make a big difference to our profitability, as the cost of power comes straight off the margin you make on a job.”

Both owners confirmed the traditionally quoted benefits of fibre laser cutting compared with CO2, including three times faster processing of thin material and an ability to process reflective metals like copper, brass and aluminium without back reflections causing damage to optics. Accuracy of cut is down to ± 0.1 mm and laser power is infinitely adjustable. So at one end of the scale a 2 mm diameter hole can be pierced through 30 mm thick stainless steel, while at the other, thin materials can be engraved safely.

Summarising the impact that Bystronic equipment has made on their business, Steve and Paul offered the following insight. Back in the mid-90s, during what they term ‘phase one’, they bought two second-hand laser cutters to generate profit so they could save enough money to buy their first new Bystronic machine in 2001. That was the start of ‘phase two’, moving them into the top flight of laser cutting, and coincided with their move into the current premises on the Centurion Business Park in Rotherham, double the size of the previous unit.

In their opinion, the reputation of the supplier at the outset was, and still is, exemplary both in terms of the quality of the machines and the service back-up provided. When asked what the future holds for ESP, they simply say that it depends on what Bystronic introduces next.