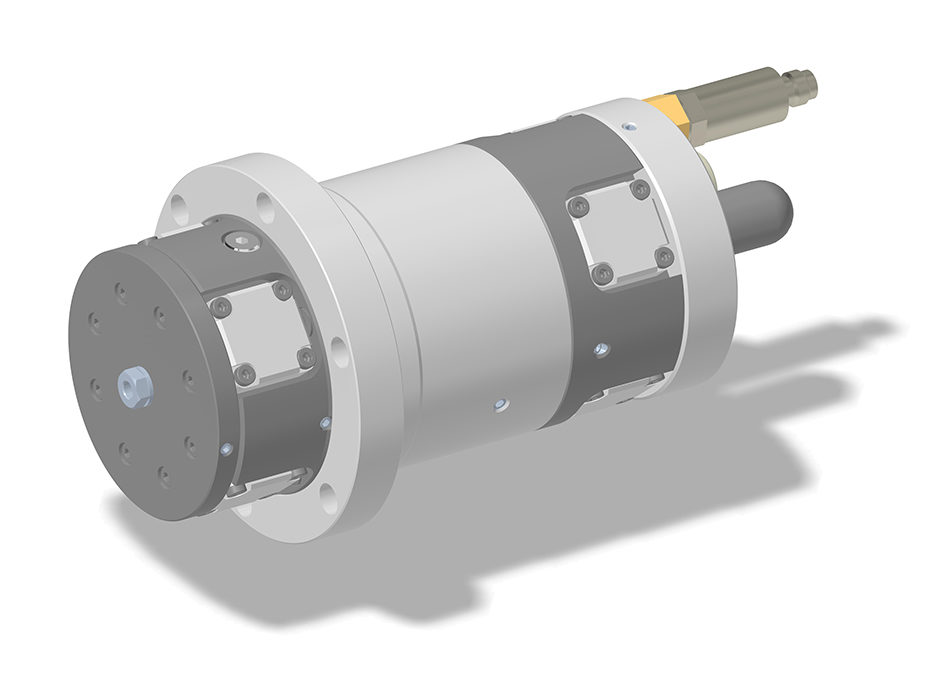

Hyprostatik Schönfeld, which specializes in hydrostatic machine tool components, has developed a hydrostatically suspended high-speed spindle which reaches speeds of up to 120,000 revolutions per minute. Due to the high speed, the extraordinary damping and the incomparably small run-out error of the spindle, very high stock removal, excellent part surfaces and minimal measurement tolerances are achieved. The minimal heating of the spindle promotes achievement of lower dimensional tolerances: The friction heating in the bearings takes place in the oil and is transported and to the outside and cooled in the return line.

The high speed spindle is suitable for machining filigree structures even in aluminium, as well as smaller bearings and jets.

Run-out qualities of 0.2 µm are achieved with the hydrostatic spindle. In contrast, conventional roller-bearing spindles, the run-out error is from 2 to 5 µm. Hyprostatik Schönfeld has computed the ideal damping parameters in each case with a software package developed in house.

Other advantages are high stiffness and the best possible balancing.

The new high speed spindles from Hyprostatik Schönfeld thus comply with the growing demands for higher quality and shorter processing time. The spindle will be exhibited for the first time at EMO 2019.