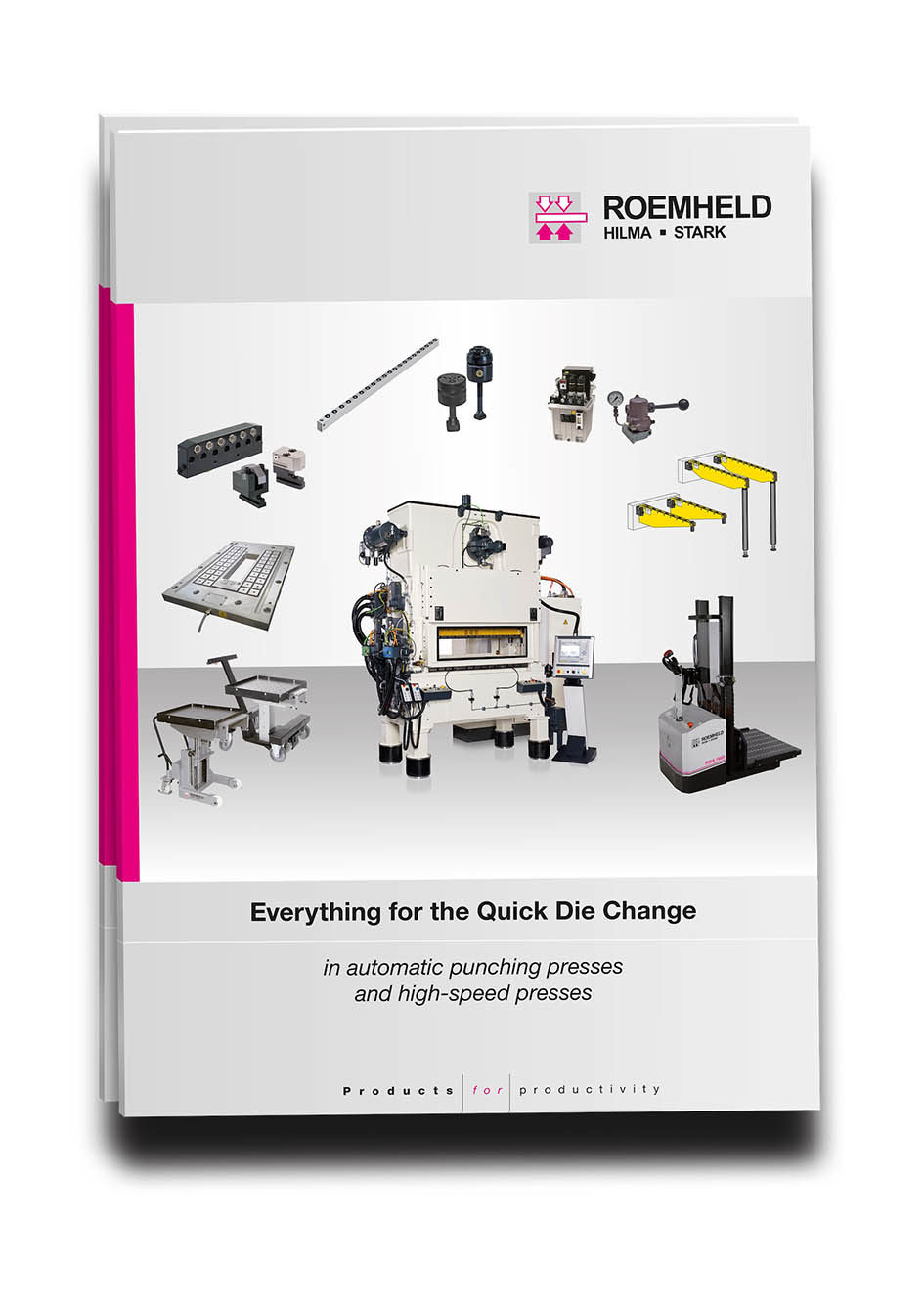

With the new catalogue “Everything for quick die change in automatic punching machines and high-speed presses” ROEMHELD addresses prospective customers from the metal forming industry with presses between 30 and 300 t. The set-up time optimiser shows clamping elements and changing technology that protect the die, improve workpiece quality and increase productivity. They are specially designed for the limited space available on small press tables. Since dies often cover these completely, there are very few quick clamping systems on the market so far.

Particularly small clamping elements for T-slots from 12 mm

ROEMHELD has extended its series of hydraulic and mechanical clamping elements to include lower sizes for use on small press tables. The range includes sliding clamps, hollow piston cylinders and hydro-mechanical clamping nuts with clamping forces up to 30 kN – with a diameter of only 50 mm. They are suitable for installation in T-slots from 12 mm.

For precarious space conditions, the company also offers magnetic clamping plates that are permanently installed on the press table. This allows dies of any size and geometry to be securely clamped in seconds – even when space is completely limited for the use of other clamping elements.

With the aid of roller and ball bars, which can be used to move the die effortlessly, set-up can also be simplified and accelerated. ROEMHELD has expanded its product range accordingly for use in press tables in automatic punching machines and high-speed presses. Die changing carts with a load of up to 1,600 kg complete the range.

Solutions for short set-up times even on small press tables

Andreas Reich, Product Manager Die Clamping Technology, sees great potential for increasing productivity with little effort when changing dies in automatic punching machines and high-speed presses

Andreas Reich, Product Manager Die Clamping Technology, sees great potential for increasing productivity with little effort when changing dies in automatic punching machines and high-speed presses. In many cases, dies are still clamped with screws. With fatal consequences, Reich says: “This does not only take a long time – the die is also often ‘distorted’. Thus the product output suffers and upper dies wear out very quickly. Simple hydraulic or mechanical clamping elements are quickly retrofitted and pay for themselves within a short period of time.”

ROEMHELD: Set-up time optimiser for sheet metal forming, plastic and rubber processing

With its extensive portfolio of die clamping technology, the set-up time optimiser ROEMHELD solves almost every clamping task in sheet metal forming, plastics and rubber processing. The magnetic, hydraulic and electro-mechanical clamping systems are highly versatile and contribute to making processes in single and series production of nearly all industries more efficient and economical. Products for die change such as die changing cart, roller bars and driven carrying consoles complete the product range.

About ROEMHELD:

Whether for aircraft, automobiles, machine tools or cases for smartphones: technologies and products of the ROEMHELD Group have been used to manufacture numerous industrial commodities and goods for end users for more than 60 years.

Efficient clamping technology solutions for workpieces, as well as for dies in forming technology and plastics processing, form the core of our ever-increasing portfolio. This is supplemented with components and systems for assembly and handling technology, drive technology and locking mechanisms for rotors on wind energy systems.

As well as a wide range of approximately 20,000 catalogue items, the ROEMHELD Group is also specialised in the development and realisation of customised solutions and is internationally respected as one of the market leaders for quality today.

Innovation through tradition: ROEMHELD was established in 1707 with a foundry in Friedrichshütte, which still belongs to the ROEMHELD Group today and counts as one of the oldest active industrial businesses in Germany.

The owner-managed group of companies employs approximately 560 workers in its three locations of Laubach, Hilchenbach and Rankweil/Austria, and is represented in over 50 countries by service and sales organisations. With customers from the mechanical engineering sector, as well as the automobile, aviation and agricultural industries, the ROEMHELD Group generates an annual turnover of more than 100 million Euro.

Download the new catalogue: https://www.roemheld-gruppe.de/en/catalogue/die-change