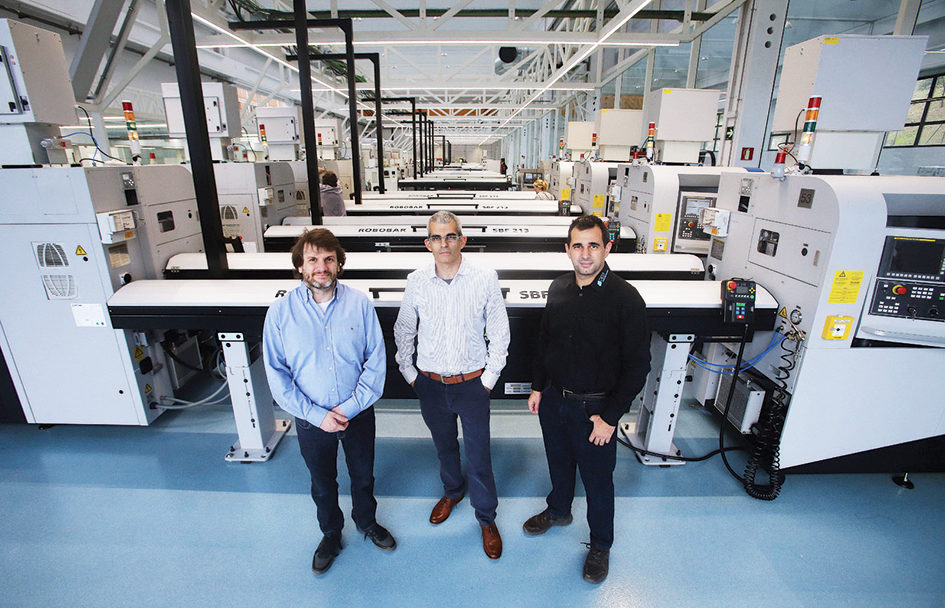

In Catalonia, just a few miles from Barcelona, there is a newly renovated building with exceptional enterprise. Terrats Medical has gradually grown and developed a workshop that can produce the most surprising workpieces on an automatic lathe. Today, the company, that was founded by the family grandfather, is managed by three brothers Roger Terrats (Sales Manager and COO), Jordi Terrats (CEO and Production Manager) and Ramon Terrats (Technical Office Manager).

Beginning with Tornos

Before it advanced to become a key player in the dental sector, the company focused on job order production and the production of connector parts. Since these sectors are extremely cyclical, the company decided to turn to a project that dealt with a new product distributed under the brand DESS that specialises in the production of medical and dental parts. While searching for a partner for this new adventure, the company soon opted for Tornos. Why? This is because Tornos and its machines have earned an enviable reputation in the implant market.

“Our contact partners are competent and responsive to our problems; they know our products and are able to provide spare parts with an amazingly fast response,” emphasises Roger Terrats, the company’s COO. “Our business started with DECO machines. They are really excellent machines, quite apart from the fact that, in our industry sector, the machines are not subject to too much wear and that we could thus resell them at a high price. Today, only a few machines can be resold as they have been here 20 years or more, which is the best proof – if any such proof were needed of the high quality of the Tornos product. So one by one, we have sold our DECO machines in order to invest. Firstly, in Gamma 20 machines and then in the Swiss GT13 machines. Our current machine inventory consists of 23 machines while Terrats Medical has 52 employees. The new building enables us to think long-term and to extend our production area at will.”

Innovative product developments realised on the Tornos machines

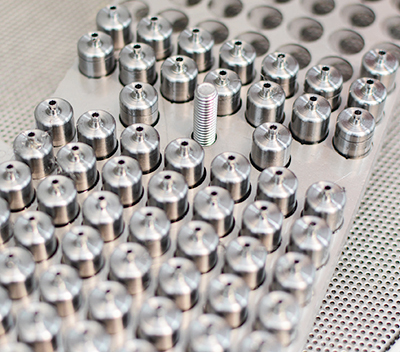

Terrats Medical is a company that specialises in high-performance machining, producing over 2.5 million parts per year. It has 1.4 million spare parts in stock, comprising more than 2,000 reference numbers (not including part families). The stock is fully computer-controlled and each item is stored with its own blister pack. Terrats Medical is certified according to ISO: 9001 and ISO: 13485 and has CE and FDA approval as well as the Canadian CMDCAS certificate. In addition, Terrats Medical has the certifications required to produce OEM or OBL parts.

For some workpieces machined on the Gamma machines, several years have been spent to guarantee optimum benefits for the customer. The result? Today, one ‘simple’ Gamma 20 with 6 linear axes does the work of a vertical high-performance machining centre. The company is committed to the efficient use of resources both in terms of machining and machine utilisation.

An own brand

Terrats Medical does not only produce parts for renowned OEMs, it also has its own brand DESS – Dental Smart Solutions. The company has launched its own brand to specialise in abutments and other prosthetic parts for dental implantology. This brand is characterised by a vast and highly innovative product line-up. It has been certified in accordance with CE and FDA standards as well as with the standards of the Health Agency of Canada. DESS stands out for excellent workmanship; the innovative system has been granted a significant number of patents. The DESS R&D department is aware of the production demands and thus can make the difference when it comes to think outside the box in order to find innovative solutions for the production of new components. The responsible experts have vast experience and can analyse any difficulties in detail, based both on their cumulative expertise and on extensive quality control. The parts manufactured undergo in-depth testing.

Both with regards to DESS Dental and the production of implants or of prosthetic parts for OEMs, expertise is the very essence of Terrats Medical’s activities. The goal is quite simple: it’s all about accepting the challenges ahead and transforming them into a product. It’s this flexibility that makes all the difference.

A long-standing partnership with Tornos

A long-standing partnership with Tornos

“22 years ago, our Tornos adventure began with the acquisition of a DECO 20 machine, a machine that accompanied us for more than 10 years. When we resold it, we incidentally found out that Tornos machines feature an excellent resale value, in addition to their outstanding reliability. Another decision criterion was the good reputation of Tornos, especially in the fields of medical and dental technology. For our customers, the fact that we are using Tornos machines is proof of rigor,” the COO declares.

He continues: “Taking this into account, it is not surprising that we have continued our partnership with Tornos. While our current machine inventory mainly consists of Gamma 20 and two DECO 10 machines, we recently purchased eight Swiss GT13 units with which we are extremely satisfied. They are very reliable and guarantee stable machining. The surface finish we can achieve is excellent too, and the new TISIS programming software is simply exceptional!”

Since we have to program part families, we benefit from the TISIS library that enables us to change the workpiece set-up in no time. All our machines are provided with the Connectivity Pack that allows us to directly monitor the production status via mobile phone, and this may prove to be very useful.

Thanks to our high flexibility, Terrats Medical is a rapidly growing business. In future, we will definitely continue to collaborate with Tornos,” Roger Terrats summarises.