Almost every component machined on the five Hurco 3-axis machining centres at Scottish subcontractor Euro Precision is programmed on the shop floor with the assistance of user-friendly menus in the machine tool builder’s proprietary WinMAX control software.

If a profile is relatively complex, as is the case about half the time, it is imported as a DXF file generated in CAD, which the Hurco control reads directly. Sometimes, using the NC Merge feature within the control software, conversational cycles programmed via the CNC touch-screens are combined with data blocks created in an off-line CAM system to define more intricate 3D features of a component.

Setter-operator Ian Blues with the Hurco VM20i vertical machining centre at Euro Precision’s Glenrothes subcontract machining facility.

Euro Precision’s production manager Mark Ramsay explained, “The Hurco software is very versatile, easy to use, and fast at producing 3-axis prismatic machining cycles.

“So all our quick turnaround work requiring a lead-time of, say, two weeks goes through these machines.

“We simply take a drawing down to one of our setter-operators and very often they have the job running within an hour.

“It is faster than if we had to wait for our off-line department to produce the program in our Esprit CAM system, as there is usually a backlog of work for our 5-axis machines.”

The component on the table of the VM20i is an aluminium lifting frame for an aerospace customer. The NC Merge feature within WinMAX was used to help produce the part, as the simple basic shape was programmed conversationally but a DXF file was imported to define the draft angle of the four radial arms.

Established over 25 years ago originally as Technicut in Auchterarder by Liam Torrance, who in 2009 took over Qualtronic located in the company’s current 30,000 sq ft premises located in Glenrothes, Fife, Euro Precision specialises in supplying complex precision components and assemblies. They are mainly machined from aluminium, but also stainless steel and steel, in batch sizes of typically one- to 30-off but sometimes into the thousands. Customers are to be found in diverse industries from aerospace, automotive and defence to electronics, energy, medical and telecommunications.

The current tally of Hurco machining centres at the subcontractor’s production facility includes a VM1, VM2 and VMX24 with WinMAX twin-screen control predecessor, Ultimax. Previously in operation at Technicut, they have been joined by a VM30i installed in 2015 and a VM20i with 4th axis that arrived last year (2018).

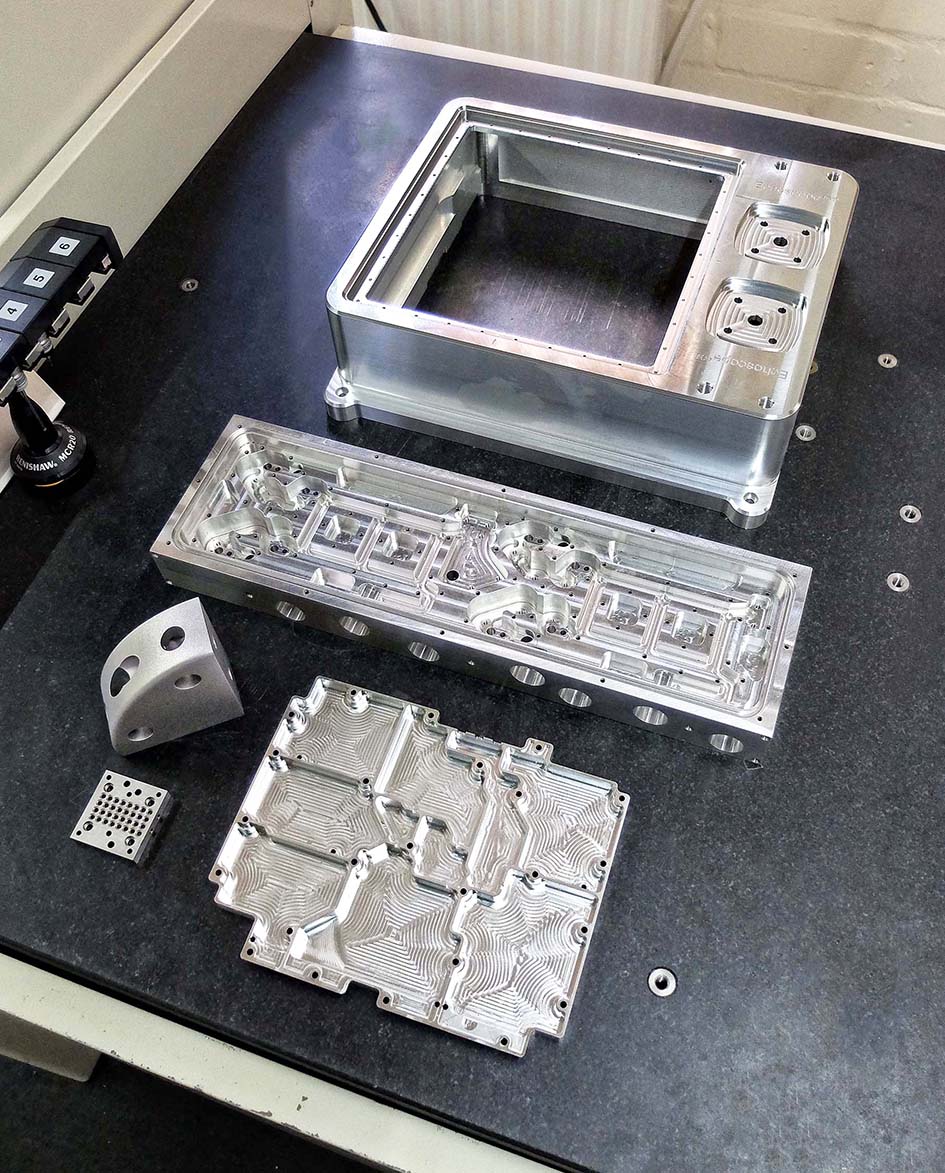

A selection of components machined by Euro Precision on its Hurco machining centres. At the back is the underwater camera housing; a telecommunications part is pictured centre; the aerospace component with complex pockets is shown front right; while two medical parts are to its left.

Investment in the latter machine was dictated by the need for extra capacity to meet an upturn in demand, particularly from customers in the aerospace and automotive sectors, as well as those producing automation machines for the medical and FMCG (fast-moving consumer goods) industries.

One of the setter-operators Ian Blues commented, “The WinMAX control is very easy to learn – you can practically do it straight from the manual – although we had three days on-site training from Hurco with the latest machine.

The twin-screen WinMAX control of the VM20i showing one of the aerospace components pictured, which has a 0.8 mm base thickness. The complex profiles of the pockets were imported as a DXF file to ensure there were no errors.

“There are some particularly useful features in the software, such as the way hole patterns can be copied and repeated, as well as the ‘loop linear’ routine that repeats a pattern a specified number of times along a line defined in the X-Y plane.

“All the Hurcos hold our usual tolerances down to ± 20 microns, but it is possible to achieve a quarter of that if you’re an experienced operator.”

Mr Blues mentioned an underwater camera housing milled and drilled from solid aluminium on the top and sides in two operations on the VMX30i in a cycle time of one hour and 20 minutes, half of which was taken up by engraving lettering imported via DXF. Inspection on a coordinate measuring machine verified that 5 µm flatness and 20 µm parallelism and perpendicularity are achieved.

The Hurco VM20i machining centre uses a spindle-mounted touch probe to position workpieces on the table.

Another example he cited of DXF input involves the complex pockets of an aerospace component with a 0.8 mm base thickness, designed in BobCad running on a PC on the shop floor. It ensures there are no errors in transferring the profiles. An instance where NC Merge proved useful was in the production of a different aerospace part, a lifting frame, whereby the simple basic 2D shape was programmed conversationally in WinMAX but a DXF file needed to be imported to define the draft angle of four radial arms.

Company owner Liam Torrance concluded, “Over the years we have developed a reputation for customer service as well as quality, reliability and flexibility.

“Hurco machines with their convenient shop floor programming capability helped us to deliver on those commitments right from the start and continue to do so, especially with the enhanced capabilities of the latest WinMAX software.”