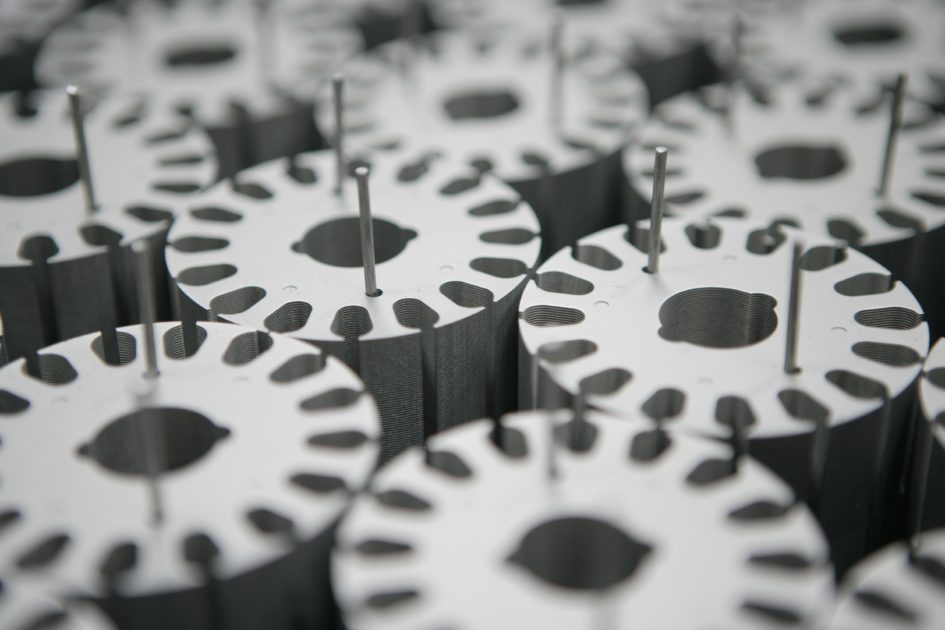

The electrical steel manufacturer Sitem S. p. A., founded in 1974, set itself a clear goal right from the start: to respond as flexibly and precisely as possible to the needs of its customers. That is why the family-owned company invests continuously in the improvement of production, efficiency and quality. The most recent example are two Smartline SA-315S high-speed presses, which Sitem has now ordered from Schuler.

The press force of the machines of 315 tons is fully available over the entire output range from 100 to 400 strokes per minute. The new interlocked packet control increases productivity by up to 30 percent. Die life is also extended by 30 percent thanks to Schuler’s depth penetration control and slide guidance without play. Both developments also have a positive effect on the process reliability of the complex dies designed by Sitem itself.

The industrial group based in Trevi, halfway between Rome and San Marino, has two further locations in Italy and one each in France and Slovakia. With more than 700 employees and a turnover of over € 160 million, it is one of the largest providers in the market. In 2016, Sitem took over Stanzwerk AG from Unterentfelden in Switzerland to prepare for the growing market of electric mobility. The latest investment in Schuler’s high-speed presses shall also be seen against this background.

Thanks to a clamping area of 1,200 to 2,700 millimeters, the Smartline SA-315S bed offers sufficient space for Sitem’s punching dies. The maximum weight for an upper part of 3,125 kilograms is also sufficient. The servo-motor slide adjustment allows for quick die changes and the massive cast body of the press provides further improved damping.

www.schulergroup.com/Drives_Generators