A paper has been published by the Manufacturing Technology Centre (MTC) entitled “Effects of Centrifugal Force on Hydraulic Clamping”, which reports on the influence that rotation has on the efficiency of workholding equipment. The clamping equipment chosen for the study was provided by MTC member, Roemheld UK, Hitchin.

The purpose of the experimental trials was twofold. First, it was to understand the effects of centrifugal force on three types of hydraulic clamps – swing clamps, block cylinder clamps and work supports – to avoid potential over-engineering or under specification of fixtures during rotational machining. Secondly, it was to gain an idea of how to optimise the force required to hold a component for turning.

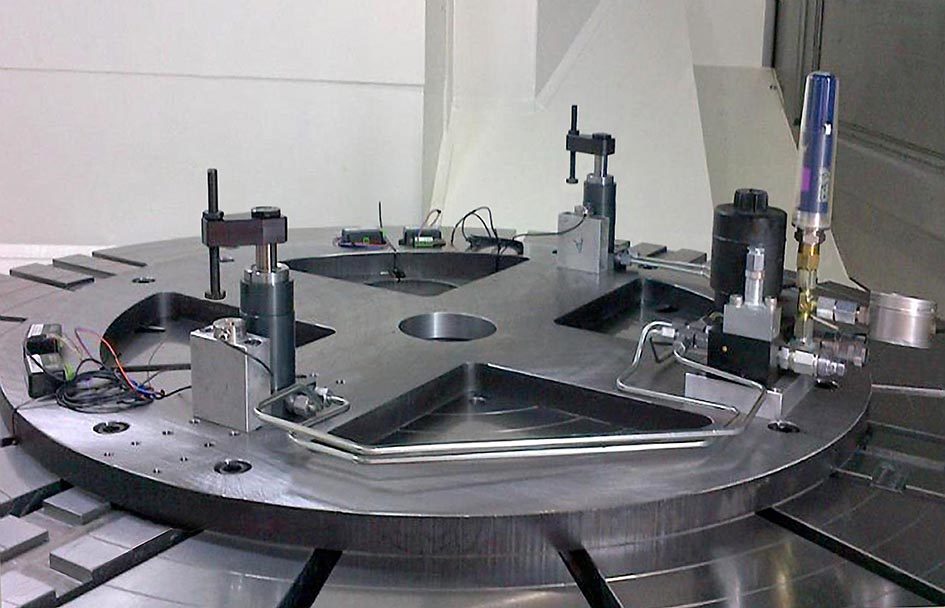

Experiments were carried out on a DMU 160 P duoBLOCK. 5-axis machining centre from another MTC member, DMG Mori. Two key parameters were measured: the pressure in the hydraulic system and the clamping load at different rotational speeds. The results showed that the centrifugal force had some effect on the workholding systems, the degree of change in the pressure and load readings being dependent on the type of clamp as well as its orientation on the fixture.

Overall, the clamps that showed least susceptibility to centrifugal force, i.e. change in holding force, were block cylinder clamps, recording an average change in load of 1.4 per cent between zero and 400 rpm. Swing clamps and work supports were affected to a greater degree, recording a higher average change in load of 3.14 per cent and 18.3 per cent respectively over the same speed range.

The report concludes that although the changes in load readings were minimal in some instances, it is still recommended to account for the effects of centrifugal force when designing a fixture for rotational machining in the horizontal, vertical or indeed any orientation.

Furthermore, if the component material is sensitive to compression due to clamping load, workholding devices should be positioned in a manner that lessens the increase in load due to the centrifugal force so that the part is not compressed. However, where material deformation due to workholding is not a concern, the clamps could be orientated in a manner whereby the load increases due to centrifugal force, offering more secure fixturing.

A copy of the full Manufacturing Technology Centre report is available as a PDF from Roemheld UK