Two years after gaining his GCSE’s at 16 and completing a BTec qualification, rising industry talent Jack McCarthy is studying for a HNC qualification at MGTS Coventry Academy while gaining industry experience as an apprentice at DMG MORI’s UK head office in Coventry.

Chris Cooper, Head of Engineering at DMG MORI UK and previous Technical expert for the WorldSkills event, supported and encouraged Jack to enter the national WorldSkills UK finals at the NEC in November 2017. Winning the silver medal in the CNC Turning discipline, Jack then went on to be selected to join Team UK 2019 for the international WorldSkills finals to be held in Kazan, Russia in August 2019. 250,000 visitors are expected at the event where 1,600 young participants from 60 countries will compete against each other in 56 disciplines.

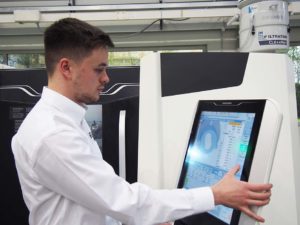

Jack McCarthy

DMG MORI is a Global Industry Partner of WorldSkills International, supports national WorldSkills competitions in many countries and is a Platinum Partner at WorldSkills Kazan 2019. This year the machine tool manufacturer is supplying 46 machines to Russia for use during the competition. DMG MORI also makes its Coventry facilities available for milling and turning team training further supporting the WorldSkills competitions. Competitors will be using the CTX310 Turn and Mill machining centre. This has 3-axis and driven tool capabilities enabling competitors to perform turning, grooving and boring operations, along with both axial and radial milling toolpaths. Being familiar with these machines will be an advantage for McCarthy

Now that the competitors have been selected training and education is increased, urging competitors to perform to the best of their ability. They will be showcasing their skills on a worldwide platform, therefore the smallest margins can make a big difference. Jack’s training process starts with a back to basics course at Training 2000 College and in DMG MORI’s Coventry facility. This is followed by coaching at Loughborough University to simulate the competition environment and nurture a winning mentality. DMG MORI promotes the wellbeing of the competitors, familiarising them with the WorldSkills culture and what to expect. During training, monitoring processes will inform expectations and projections of performance. More interim training will help Jack to familiarise himself with other competitors through trips to other countries and improve his own performance under pressure, including time management and working in front of an audience. Through this training process, Jack and other entrants will have the opportunity to meet and learn, in an environment that gets them competition ready for the event in Kazan.

Chris Cooper and Jack McCarthy with DMG MORI CTX lathe

The competition is held over 4 days, with competitors flying out as a team. Jack will be expected to work to a set brief competing in one module each day. A new batch production task is one of the practical elements in the CNC Turning event this year. Pairs of parts from the batch will be selected at random by judges to check for fit, finish and uniformity. Competitors will be assessed on core-competencies, using inspection equipment, mirroring industry best practice, demonstrating their abilities in producing components used in engineering and manufacturing. Marks will also be awarded for workplace skills such as positive attitude to work, good communications and adaptability. Competitors will also be using Mastercam CAD/CAM software to prepare their CNC programs.

WorldSkills Kazan 2019 is to be streamed live on TV and social media, and will be held at a new purpose built facility, the Kazan Expo International Exhibition Centre.

Steve Finn, Managing Director DMG MORI UK says, “We are investing in Jack McCarthy’s education, skills and productivity, enabling him to bring new knowledge and experience back to the company, following the WorldSkills event, which we can then share with our customers and our team. His success will demonstrate that young people in our industry have a lot to contribute in terms of knowledge and skill, which will be an inspiration to other young people, showing them what can be achieved. For companies within the industry it demonstrates the benefits of training and apprenticeships and the value new talent can bring to advanced manufacturing.”