With the launch of its Safe EFI-pro System, SICK has delivered standard industrial Ethernet-based safety network integration for highly-adaptive and dynamic safeguarding in automated production and logistics environments to SIL 3/PLe.

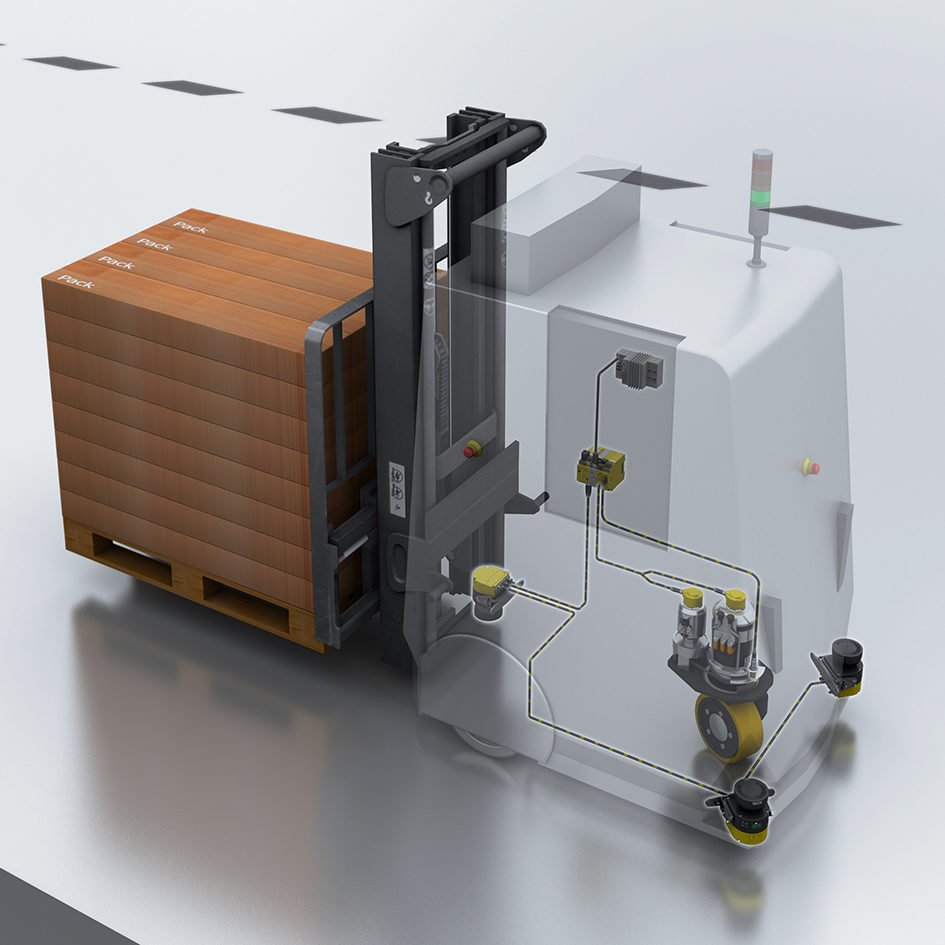

The SICK Safe EFI-pro System is a single-source solution that provides the foundation for simpler, more productive and responsive machinery safety, particularly valuable for dynamic applications like autonomous vehicles and human/robot collaboration. It comprises the SICK microScan3 EFI-Pro safety laser scanner and the SICK Flexi Soft safety controller with EFI-Pro gateway.

“Safe EFI-pro is SICK’s safety network for industrial automation, based on the CIP Safety protocol,” explains Dr Martin Kidman SICK’s UK Safety Specialist. “The next step in the development of SICK’s successful EFI interface, the system offers the prospect of more productive and flexible safety solutions founded on rapid, high capacity transmission of both “safe” and “non-safe” data across all levels of communication.”

The innovative SICK Flexi Soft EFI-pro Gateway facilitates simple and safe system integration via EtherNet/IPTM CIP SafetyTM and EFI-pro, allowing connection to SICK EFI-Pro devices like the microScan3 as well as third party CIP-SafetyTM devices like robot controllers from leading manufacturers, remote I/O modules and safety PLC’s. Connected to SICK’s Flexi Soft modular controller, the system provides scalability, facilitating the integration of encoders for Safe Motion Control, devices with analogue outputs, hardwired I/O as well as additional gateways for non-safe communication to any other network such as PROFINET or ETHERCAT, for example.

The SICK microScan3 EFI-pro safety laser scanner enables simultaneous field evaluation with the possibility of monitoring up to eight protective fields at the same time on one device. The user can also configure up to 128 monitoring cases per scanner. Powered by SICK’s robust safeHDDMTM scanning technology, the microScan3 EFI-pro minimises machine downtime, even in challenging industrial conditions such as welding, reflections, high ambient light, dirt and dust.

With SICK’s new license-free engineering tool, Safety Designer, configuration of the Safe EFI-pro system is facilitated with an intuitive ‘drag and drop’ user interface. System-wide access to all networked components ensures commissioning is easy, and extensive diagnostic options are available to optimise processes, e.g. for analysis of machine downtime.

The SICK Safe EFI-pro system offers an open and powerful system to enable safe human and robot collaboration with minimal effort. Especially where speed and distance are issues, it offers intelligent and responsive safeguarding for situation-dependent robot protection. Integration of robot controls into the safety system is straightforward via EtherNet/IPTM CIP SafetyTM.

With Safe EFI-Pro, Automated Guided Vehicles and Carts can work more quickly, intelligently and safely. High-performance simultaneous protective monitoring of multiple fields means less need for switching between monitoring cases, so dynamic protective fields can be shorter, and therefore more responsive and efficient. The safe contour detection field, which is unique to the microScan3, supports applications such as safe AGV docking and protecting workers at narrow access points as well as providing signals for self-muting.

The microScan3 can also provide accurate Ethernet-based measurement data for navigation – a “non-safe” function that saves the need for additional scanners. Data is available as part of UDP frames either on request or through continuous transmission. As well as data such as the number of beams, distance, status and reflectivity of every beam, additional data such as field interruption, application I/O, device status and configuration can all be output.

“To be truly productive, autonomous and/or collaborative robots and mobile machinery all need safety that can adapt in real time. So, SICK has developed intelligent and responsive on-board sensing with simultaneous protective fields and highly accurate measurement data,” Dr Kidman continues.

“To operate effectively and productively, systems also require fast, high capacity data transmission with time synchronization of multiple devices. By basing the SICK Safe EFI-pro System on CIP Safety™ we have assured this with industry standard communication over Ethernet for Industry 4.0-ready applications.”

For more information on the SICK microScan3 EFI-pro and other SICK safety systems, please contact Andrea Hornby on 01727 831121 or email andrea.hornby@sick.co.uk.