At the Seco ‘Inspiration Through Innovation‘ event on the 9th and 10th October, OPEN MIND Technologies will present the latest version of its hyperMILL® CAD/CAM suite through technical and live demonstrations. The company’s presence will focus on the hyperMILL® MAXX Machining performance package that brings together highly efficient machining strategies that make the most out of the options for the respective machine tool.

hyperMILL® MAXX Machining incorporates innovative methods for roughing, finishing and drilling; all of which will be comprehensively demonstrated on a GROB mill/turn centre and a 5-axis Hermle machining centre at the event. The MAXX Machining demonstration on the Hermle will see OPEN MIND produce a portion of an annulus filler aircraft engine part from aluminium with innovative CAM strategies that will apply the latest Seco conical barrel tools to achieve incredible cycle times.

Highlighting the benefits of hyperMILL® MAXX Machining rough, finish and drilling strategies that can deliver cylce time reductions in the region of 90%, OPEN MIND UK’s Managing Director, Mr Adrian Smith says: “The annulus filler will showcase the combined benefits of MAXX Machining‘s rough and finishing strategies and the cycle time savings with Seco conical barrel tools. The demo part will also introduce technology like our MAXX drilling feature that interpolates milling tools to create holes at speeds significantly faster than conventional drilling. Similarly, trochoidal milling is not necessarily the fastest route to material removal as the continual direction change doesn’t always allow the machine to achieve maximum feed rates. The optimised MAXX Roughing strategy undertakes intelligent straight-line tool paths and this permits the machine to reach the maximum acceleration and feed rates. In contrast, the GROB demonstration will be undertaking B-axis turning, which is a genuine eyecatcher on a mill/turn centre.“

Highlighting the benefits of hyperMILL® MAXX Machining rough, finish and drilling strategies that can deliver cylce time reductions in the region of 90%, OPEN MIND UK’s Managing Director, Mr Adrian Smith says: “The annulus filler will showcase the combined benefits of MAXX Machining‘s rough and finishing strategies and the cycle time savings with Seco conical barrel tools. The demo part will also introduce technology like our MAXX drilling feature that interpolates milling tools to create holes at speeds significantly faster than conventional drilling. Similarly, trochoidal milling is not necessarily the fastest route to material removal as the continual direction change doesn’t always allow the machine to achieve maximum feed rates. The optimised MAXX Roughing strategy undertakes intelligent straight-line tool paths and this permits the machine to reach the maximum acceleration and feed rates. In contrast, the GROB demonstration will be undertaking B-axis turning, which is a genuine eyecatcher on a mill/turn centre.“

OPEN MIND will also provide some sneak peeks at pending expansions to its performance package that will be introduced in the soon to be arriving Version 2019.1. For instance, in the not too distant future, hyperMILL® MAXX Machining will be available for 3D-optimised roughing as well as for turning. Meanwhile, 5-axis tangent machining is available for corner filleting and this function guarantees simple radius programming at surface boundaries with an excellent surface finish.

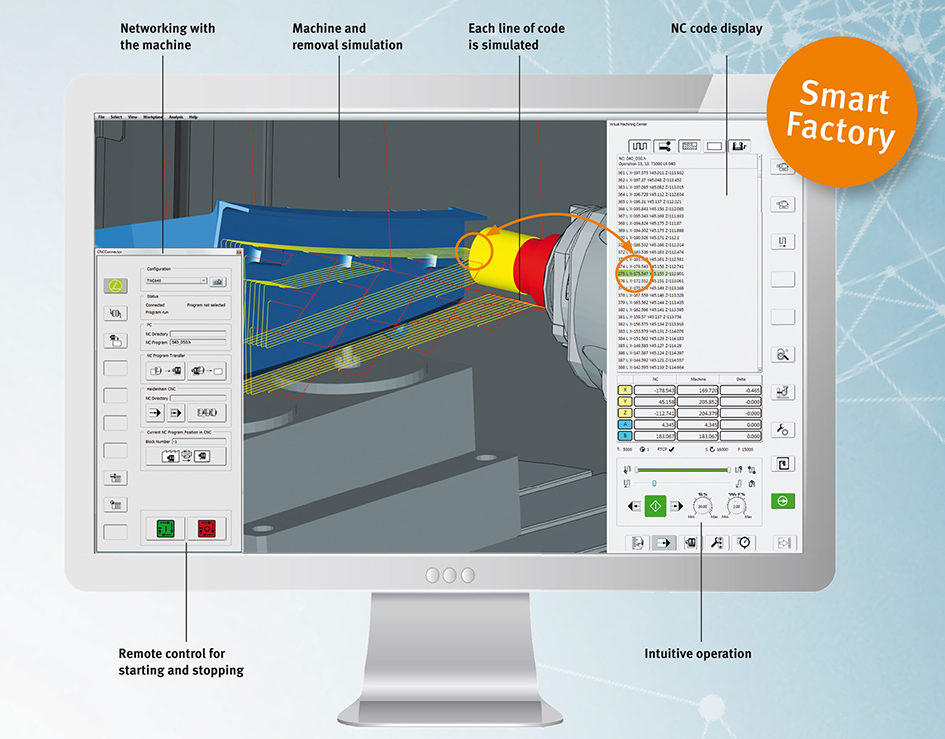

Stepping into the workspace – virtually

The highly developed hyperMILL® Virtual Machine simulation functions will make an appearance at the Seco event. Visitors will be able to delve into the machining area through a 3D machine simulation on a virtual reality station. Visitors will be able to view the clamps, holders, tools, toolpaths and even view simulations from any desired perspective. End users will be able to observe complex processes via virtual machining. Hidden processes will be made visible and it will be easier to detect collision risks. To register for the event, please follow the link to www.secotools.com/iti