WEG, a leading global manufacturer of motors and drive technology, has always been at the forefront of innovation when it comes to offering energy efficient motors. In line with this, the manufacturer has recently announced that, as standard, it is now offering explosion-proof induction motors in the W22Xd series. This includes all motors over the full stated power range, which conform to the IE classification standards, up to and including energy efficiency class IE4. Special applications – including explosion-proof motors – are currently exempt from the motor efficiency regulations and this series, which combines reliable explosion protection with maximum efficiency, is now one of the most energy efficient series available on the market

“Particularly in energy-intensive industries such as chemical, oil/gas or mining, where very large facilities with, in some cases,thousands of motors often operating 24/7, energy efficiency is a decisive factor for reducing operating costs and CO2 emissions”, says Detlef Wortmann, Business Development Manager at WEG. “Energy costs for electric motors account for 95 to 97 per cent of total life cycle costs, depending on the application. This means that investments in energy-efficient drives usually have a very short return on investment. Thanks to the low operating costs, companies with explosion-proof motors in the W22Xd series can reduce their costs by 20 to 40 per cent compared to conventional approaches.”

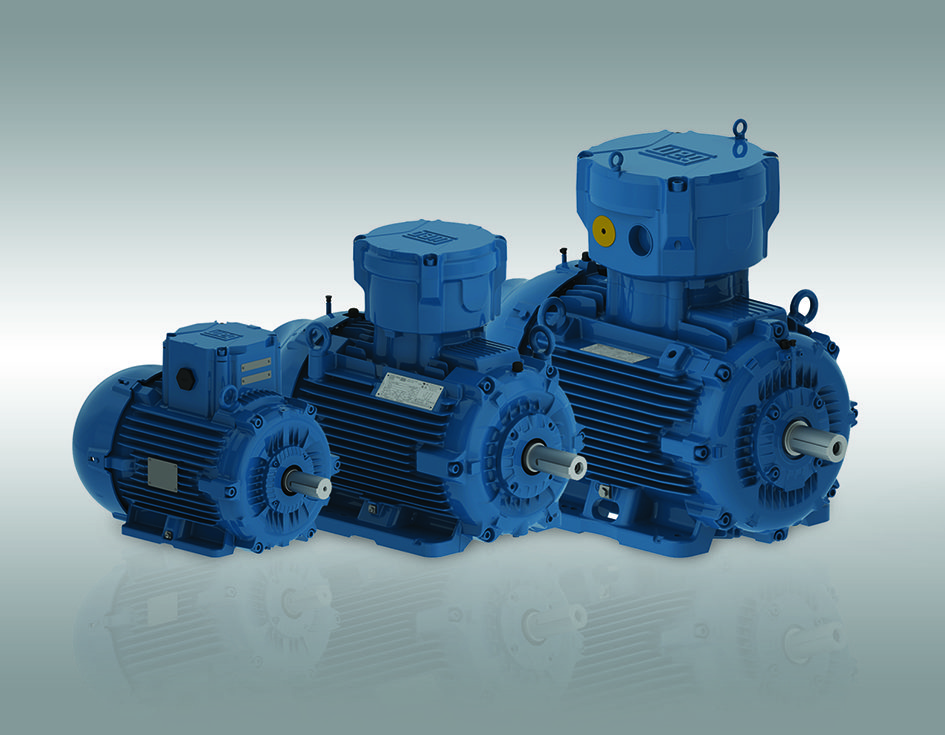

To make this energy-saving drive solution available for hazardous areas, WEG utilised the innovative housing design of the W22 standard induction motors.The W22Xd housing design features an advanced cooling system with an aerodynamic concept that both reduces noise levels and significantly improves heat dissipation. The sturdy housing with integrated mounting feet, allows the explosion-proof motors to be deployed in even the most demanding applications and minimises both vibration and noise emissions.

The robust, durable motors in the W22Xd series are designed to withstand the often harsh ambient conditions in explosion hazard areas. For example, standard IP56 ingress protection prevents penetration by liquids. Standard integrated thermistors additionally protect the motor winding in the event of overload and heaters within theinterior prevent condensation thus increasing the service life of the winding insulation, thereby prolonging the lifetime of the motor. A special polyurethane coating protects the surface of the motor housing against harsh conditions andsturdy eyebolts simplify handling, transport and storage. Furthermore, numerous optional modules enable flexible motor adaptation to virtually every application.

The standard W22Xd series is intended for use in explosion hazard areas conforming to the following IEC classifications: Zone 1 and 2, group IIA and IIB (W22XdB versions) or group IIA, IIB and IIC (W22XdC), as well as temperature class T4 and EPL Gb. The W22XdBD and W22XdCD versions additionally provide protection against explosive dusts for use in explosion hazard areas classified as Zone 21 or 22, group IIIA, IIIB or IIIC, and EPL Db. The W22XdM versions are suitable for use in coal pits with classification Group I, Category M2 and EPL Mb.