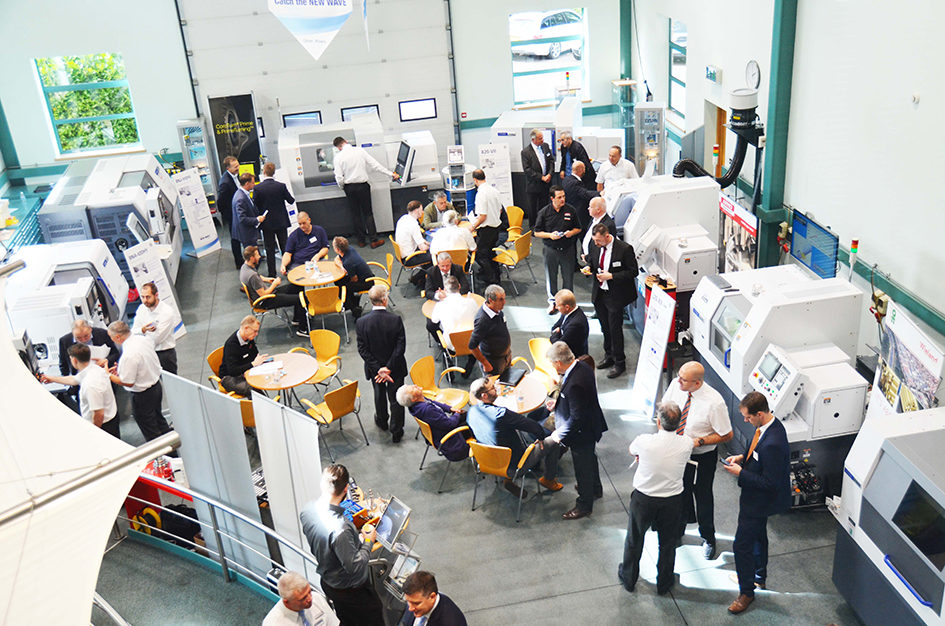

Low Frequency Vibration (LFV) machining technology will be an important theme to customers at Citizen Machinery UK’s Annual Open House event being staged at the UK headquarters in Bushey between 16 and 18 October. Amongst the 16 machines on view will be the UK launch of the LFV versions of the Citizen Cincom L32-VlllLFV sliding head turn-mill centre and the Miyano BNA-42GTYLFV sliding headstock turning centre.

In addition, Citizen will be demonstrating 5-axis machining technology on the latest Cincom D25-Vlll sliding head turn-mill centre using the ground breaking latest Mitsubishi 800, a true 5-axis simultaneous machining control platform combined with Citizen’s Cincom operating system.

As part of Citizen’s progressive introduction of feeding the patented LFV technology across its range of Citizen and Miyano machines, the L32-VlllLFV and Miyano BNA-42GTYLFV’s have been eagerly awaited to provide major advantages from programmable control of chip size on larger capacity machines from both stables.

Why progressive inclusion of LFV? LFV is a fundamental in the machine design and is not achieved through simple macro programming. It is selectable at the machine control to provide rapid oscillation of the cutting tool creating, in effect, precise air gaps in synchronisation with the rotation of the machine spindle.

To maintain machining integrity when selectively employing LFV to turning, drilling, grooving and even thread cutting to difficult materials from plastics to copper and high alloy content steels, the machine requires upgrading in its overall rigidity, vibration damping and drive systems. The Citizen L32-VlllLFV with 38 mm bar size option and removable guide bush can carry up to 30 tools, according to specification six for gang turning, four to six gang driven, four to nine front drilling and between five and 11 for back drilling. Both main (7.5 kW) and sub-spindle (3.7 kW) have 8,000 revs/min motors with 1 kW driven tools with 6,000 revs/min motors. Rapid traverse rates are fast at 32 m/min.

Adding LFV to the Miyano moving headstock hybrid BNA-42GTYLFV design, it has been significantly developed as a rigid yet compact machining platform taking just 2.3 m by 1.5 m of floor space and using plain, hand scraped slideways on each axis with special ballscrews and roller bearings on the X1 cross feed to the headstock. Through the Cincom ‘Superimposition’ operating control software, simultaneous cutting with up to three tools can be achieved.

There are two spindles, the 42 mm main, with 3-axis X1, Y1 and Z1 having 11 kW 6,000 revs/min drive and 34 mm, 5.5 kW, 5,000 revs/min 2-axis X3 and Z3 for the sub-spindle. Up to 45 tools can be carried. The eight station turret has 1 kW power, 6,000 revs/min driven tools with half-indexing enables up to 16 tools to be carried. The gang tool slide can carry up to 13 tools.

A further 18 companies will be supporting the Open House event covering CADCAM, tooling, quality, materials and machine accessories.

Lunch will be provided each day and, of course, on Wednesday 17 October the Open House will be extending its visitor hours of 09.00 to 17.00 until 21.30 when all are welcome to the traditional highly sociable Citizen Curry Evening.

While Citizen Machinery UK has an open invitation to all, in order to help with catering, those wishing to attend are able to register online at citizenmachinery.co.uk/open.house.event or telephone: 01923 691500.