First came smart phones, then intelligent cars and houses. Now, visitors to the Metal Cutting Pavilion at IMTS 2018 – The International Manufacturing Technology Show, can experience the explosive productivity growth possible with smart, connected machining centers.

“The conversations at IMTS have changed from spindle speeds and traverse rates to how to deliver pertinent information so job shops and manufacturers can better manage their assets,” says Marlow Knabach, Executive VP, National Engineering, DMG MORI USA. “To start the conversation, exhibitors in the Metal Cutting Pavilion at IMTS will demonstrate smart machines with the ability to monitor critical elements, such as spindle bearing temperature, spindle vibration, ball screw temperature, coolant level and tool wear to identify potential sources of downtime before they occur.”

“Lean companies need smarter approaches, and connecting with the exhibitors in the Metal Cutting Pavilion exhibitors in the Metal Cutting Pavilion at IMTS 2018 will help them develop new strategies for more efficient part manufacturing,” says Peter R. Eelman, Vice President – Exhibitions & Business Development at AMT – The Association For Manufacturing Technology, which owns and produces IMTS.

In addition to connectivity, Eelman says that technology highlights from the Metal Cutting Pavilion exhibitors at IMTS 2018 include more collaboration between CNC and automation providers, more process integration to create multi-tasking machines and more powerful software and user-friendly CNC controls.

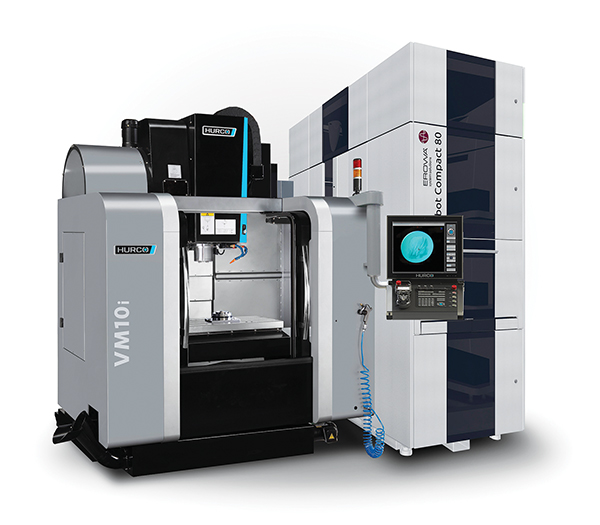

At IMTS 2018, Hurco will showcase a 3-axis machining center in their automation quadrant. The VM10i features a small footprint with a large work cube. No other mill packs as much productivity into such an efficiently designed package. The VM10i offers a maximum load capacity of 1,499 lbs. and will partner with a collaborative robot to create personalized brass coins for booth visitors.

Information for Everyone

Achieving overall equipment effectiveness (OEE) rates greater than 80 percent in job shops is a greater challenge compared to higher volume manufacturing. Traditionally, job shops could not take advantage of software-based systems for automation and process monitoring or Ethernet-based communication protocols because the cost and complexity were too prohibitive.

“Communication protocols and software-based systems process monitoring enable considerable cost and time reductions in total system operation,” says Paul Gray, Ph.D., Manager for Path Planning, Front-end Design and R&D at Hurco. “Smaller job shops and those with high-mix, low volume parts who attend IMTS 2018 will find that the benefits of intelligent machining and automation are within their reach.”

Knabach adds that, “The return on investment for machine monitoring is so pronounced that I would challenge anyone if they could not obtain a return on investment within one year.” ROI happens quickly because monitoring usually reveals an OEE much lower than expected. “Understanding utilization rates, causes of common alarms and premature tool wear and so much more are available with a connection, especially since the growth of devices compliant with the MTConnect standard.” For companies who are not prepared for a cloud-based operation or cannot do so because of industry regulations (e.g., defense contractors), he notes that connected machines, devices and systems can operate entirely behind a company firewall.

Automation & CNC Integration

In addition to Industry 4.0 machine and device monitoring demonstrations (likely numbering in the hundreds at IMTS 2018), exhibitors will show how enhanced data exchange is essential for intelligent manufacturing. One example would include a CNC, a robot for automated part loading/unloading and a CMM, all connected to create a closed-loop system that automatically updates tool offsets. Easy part change-over is another.

“Automation integration used to be more expensive and difficult because you had simple I/O connections and needed to reprogram a PLC when changing parts,” says Gray. “CNC manufacturers and automation providers have been working together to provide seamless integration between the CNC control and the robot control. With software systems talking with each other over an Ethernet connection, users can now bundle all aspects of the job together. We’ve created a new level of flexibility and simplicity in part change-over in production cells.”

Hurco will demonstrate automation integration as part of its 50th anniversary celebration at IMTS 2018. A collaborative robot will 3D scan visitors’ faces, generate a solid model from that data to create a tool path and then either a 5-axis CNC will cut the head from cylindrical aluminum stock or a 3-axis CNC will cut the form into a brass coin. Both CNCs will be connected to fully automated robot systems that are coordinated by a centralized job management system.

Process Integration

Like automation, process integration continues to fuel the technology needed to remove manual intervention to drive up OEE rates. Lathes and mills have morphed into a single machine platform, the mill turn.

“Machine manufacturers are now adding more capabilities. Examples to look for at IMTS include 5-axis CNCs that can also gear hob, gear skive and grind,” says Knabach (see photo). “By incorporating inspection software and a touch probe, the machine can confirm part profile before removing it from the machine, eliminating the need to re-orient the part if it requires additional processing. By reducing the number of times a part is handled and fixtured, process integration inherently increases part accuracy and improves OEE.”

These multi-tasking machines work well for companies that have limited floor space and for those who don’t need a dedicated gear hobbing/skiving machine, such as R&D or MRO centers and job shops serving the transportation industry.

Controls

CNC and control manufacturers all want to improve the customer experience, and the ways to achieve that are as nearly as diverse as the exhibitors in the Metal Cutting Pavilion. AMT’s Eelman says that, “The manufacturing industry is now being influenced by software experts who bring new perspectives. More commonly, entering G-code is being replaced by importing and editing the digital model, while graphically intensive controls engage younger generations as they enter the workforce.”

“Innovations at IMTS 2018 include solid model import, a technology that directly imports 3D CAD models to the CNC control,” says Gray. “Users don’t have to punch in numbers or scroll through screens. They just click on the parts of the CAD model that they want to cut, and solid model import automatically creates the data blocks. It drastically reduces programming time.”

Gray notes that editing part features can now be as simple as selecting the geometry on a touch screen and the corresponding code (NC) or data block (conversational) automatically appears without the user wasting time searching through lines of code to find what they need to edit.

Knabach adds that, “Today’s HMIs engage the operator by presenting information that is relevant to the operation of the machine at a specific point and time. Multi-touch monitors feature icons, while a series of apps help operators prepare, optimize and process production jobs — and of course, manufacturers continue to develop new apps.”

Knabach also reinforces Gray’s earlier message, saying, “Machine manufacturers now design controls so that they connect with higher-level enterprise and other production systems via standards such as MTConnect. Holistic integration of CNCs into the rest of the organization is now our standard approach so that we can harness the advantages of Industry 4.0.”

Eelman says that staying current with new metal cutting technology has a much broader focus at IMTS 2018. “The CNC still forms the heart of machining, but users that want high utilization rates will evaluate CNCs in the context of a digitally connected production cell that includes automation, CMMs, enterprise systems and other devices. With the Metal Cutting Pavilion and nine other technology pavilions at IMTS 2018, visitors have an unmatched opportunity to evaluate all these new technologies in one place.”